CW Blog

This foiling racer is crazy fast thanks to composites

The Exocet racer’s hull and its foils, designed via computer model, are fabricated using hand layup and resin infusion methods, respectively, with PRO-SET epoxy.

Read MoreSwedish multi-sectorial innovation network aims for a lighter tomorrow

The LIGHTer network works to coordinate what is happening in research, development, technology and competence development in Swedish industry.

WatchNew Composites Products: May 2018

CW’s monthly roundup of new products for the composites industry.

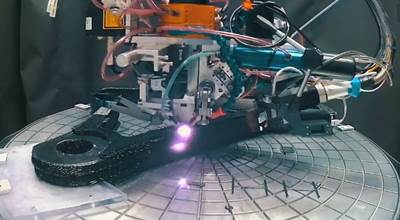

Read MoreArevo in 2018: Industrialized production of continuous fiber 3D-printed parts

With new CEO and $12.5 million in B-series financing, Arevo will have eight direct energy deposition (DED) cells attacking its parts production backlog by year-end.

WatchGetting carbon fiber cost down

4M Carbon Fiber Corp. says its objective is to demonstrate that standard modulus carbon fiber can be made from textile grade PAN precursor using significantly less energy and in less than half the processing time, thus cutting carbon fiber manufacturing cost by about 50%. Plasma oxidation is the key.

Read MoreSurfacing Films Enhance Aircraft Surfaces While Minimizing Prep

Composite materials naturally come with more surface imperfections than metal, and aircraft paint schemes for composites are becoming more complex. That’s why surfacing films need to rise to the challenge by providing a smooth, blemish-free surface. (Sponsored Content)

Read MorePultruded composites market growing, says EPTA

The European Pultrusion Technology Association (EPTA, Frankfurt, Germany) has published an in-depth report on its highly successful 2018 conference, held in Vienna on March 1-2, 2018. The 12-page document, World Pultrusion Conference 2018: Attractive Long-Term Prospects for Pultruded Composites, is available to download from the EPTA website.

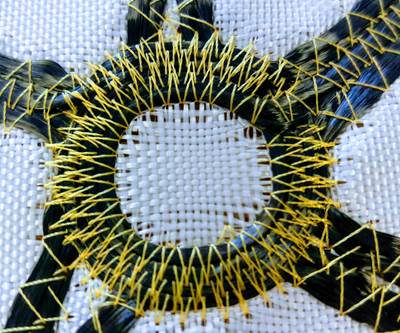

Read MoreShape offers novel visual options with preforming technology

The ShapeTex preform uses a continuous tow of carbon fiber laid down to create a zero waste, optimized and accurately sized preform.

WatchThe future of CFRP aerostructures assembly

Metrology, robotics and inline inspection cut cost, reduce shimming and enable future automated production of three vertical tail planes per day.

Read MoreAdditive manufacturing: Big and going commercial

A demonstration of large-format 3D printing delivers parts for an excavator cab, from CAD data to ready for assembly, in only five hours.

Read MoreSurfacing Films Improve Safety, Appearance and Processing Time

Surfacing films are evolving to meet challenging demands for lightweight solutions to protect composite structures and enable high-quality surface finishes with reduced preparation times.

Read More