CW Blog

Centrifugal casting

Centrifugal casting of pipe ranging from 25 mm/1 inch to 356 mm/14 inches in diameter is an alternative to filament winding for high-performance, corrosion-resistant service. In cast pipe, 0°/90° woven fiberglass provides both longitudinal and hoop strength throughout the pipe wall and brings greater strength at equal

Read MoreAll-carbon bicycle rims cost-competitive with aluminum

Iterative design process improves performance and manufacturability of one-piece carbon rims.

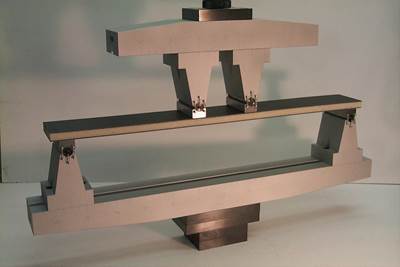

Read MoreSandwich panel flexure testing

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) comments on the composite materials testing community's move toward the use of the terms "long beam flexure" and "short beam flexure" when addressing sandwich panel testing.

Read MoreAdvanced materials for aircraft interiors

Applications aren't as demanding as airframe composites, but requirements are still exacting — passenger safety is key.

Read MoreTube rolling

Tube rolling is a long-standing composites manufacturing process for producing finite-length tubes and rods. It is particularly applicable to small-diameter cylindrical or tapered tubes in lengths up to 6.1m/20 ft. Tubing diameters up to 152 mm/6 inches can be rolled efficiently. Typically, a tacky prepreg fabric or

Read MoreThe world of composites: An overview

Commercial applications growing despite tight material supplies.

Read MoreRIM Molding for Wind Blade Skins

Low-cost, high-volume molding method and carbon fiber/epoxy spar show promise for replacement wind turbine blades.

Read MoreThe ABCs of FEA

Computerized and adapted for composites, finite element analysis reduces R&D expense and shortens time to market.

Read MoreIBEX Show Preview - 10/1/2006

Boatbuilders attending the annual exhibition will again find composites industry exhibitors located in a specially dedicated composites pavilion.

Read MoreGlass-Reinforced Thermoplastic Succeeds in Car Crash Structure

Thermoformable, recyclable composite yields production-worthy front-end structure.

Read MoreTooling Paste Reduces Wind Blade Model Production Time

When Vostermans Tooling and Prototyping BV (Venlo, The Netherlands) wanted to reduce production time for its large wind blade master models, the company turned to computer-aided designs and CNC-machinable modeling paste. Vostermans selected RenPaste 4503R/Ren 4503H seamless epoxy modeling paste from Huntsman Advanced

Read MoreComposites in Boat Accessories and Hardware

All the stuff that goes inside, stem to stern.

Read More