Gulfstream expands G400 business jet manufacturing facilities

A $150.7 million investment ensures streamlined, efficient operations for next-gen composite fleet production, meets increasing demand.

Read MoreIndustrial thread company Coats Group opens Huanmantla manufacturing facility

Mexico facility will support the company’s development of high-performance material threads, yarns and fabrics for the automotive and composites industries, among others.

Read MoreNational Composites Centre joins new digital series to explore advances in sustainable materials

“Material Change: Resourcing Net Zero” campaign highlights critical role of composites in a net-zero future.

Read MoreHexagon Digital Wave signs long-term MAE requalification agreement

Three-year agreement will enable in-situ Type IV COPV assessment for Certarus, a virtual pipeline solutions company, alleviating pain points and ensuring effective requalification.

Read MoreMussel Polymers announces new multifunctional carbon, aramid fiber coating

Specialty materials company produces poly(catechol-styrene) polymer that effectively bonds with many materials, providing enhanced adhesion and other surface functionalizing benefits.

Read MoreComposite truck component carrier from Lanxess wins GKV/TecPart Innovation Award

Injection-molded glass fiber-reinforced PA6 component is jointly developed with system supplier and truck manufacturer for 35% less weight, replaces DLFT-based design.

Read MoreToray, Specialty Materials strengthen partnership for next-gen aerospace applications

Commercial partnership enables novel solution innovations with domestically produced, high-quality products within the U.S. supply chain.

Read MoreTNO research offers circularity solution for discarded wind turbine blades

Thermochemical method involving pyrolysis extracts fibers, which can then be reprocessed as thermoplastic composites for various recyclable products.

Read MoreNew report reveals U.S. saw 60% growth for offshore wind targets

Business Network for Offshore Wind’s inaugural quarterly report details market trends, supply chain and technology advancements.

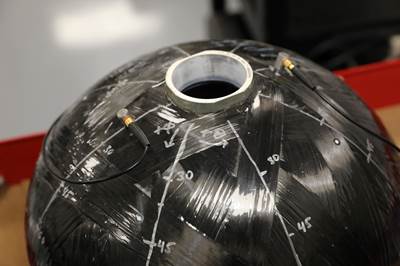

Read MoreCannon Tipos, Coriolis Composites mold complex automotive structural part from single preform

Dosing equipment for precise injection and mold engineering enable near-net-shape dry preform for HP-RTM CFRP composite part with rapid cycle time.

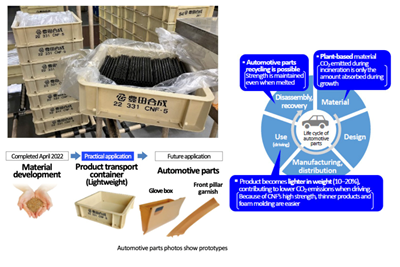

Read MoreToyoda Gosei develops nanocellulose fiber-reinforced plastics for automotive parts

Newly developed CNF-reinforced plastic used in product transport containers combines 20% CNF in a general-purpose polypropylene, aims to reduce CO2 over the lifecycle of components.

Read MoreScott Bader expands partnership with composites supplier Hans Claussen in Scandinavia

Partnership extension continues to grow Scott Bader’s presence in Norway, Scandinavia, enhances composite and adhesive offerings for customers.

Read More