Cannon Tipos, Coriolis Composites mold complex automotive structural part from single preform

Dosing equipment for precise injection and mold engineering enable near-net-shape dry preform for HP-RTM CFRP composite part with rapid cycle time.

Share

Read Next

The final, molded composite part. Photo Credit, all images: Coriolis Composites

Cannon Tipos (Varese, Italy), a Cannon Group company specializing in tooling processes for a wide range of technologies for polymer and composite materials, collaborated with Coriolis Composites (Quéven, France) for the fast and precise high-pressure resin transfer molding (HP-RTM) of a near-net-shape dry preform manufactured with Coriolis’ patented automated fiber placement (AFP) technology.

Coriolis Composites globally supplies AFP robotic equipment and machines which enable the laying of continuous or discontinuous fibers with minimum material waste in various orientations — including complex geometrical surfaces — and has reportedly developed an innovative and exclusive process to make dry fiber-functionalized preforms of composite parts for a range of industrial sectors, notably aerospace and automotive.

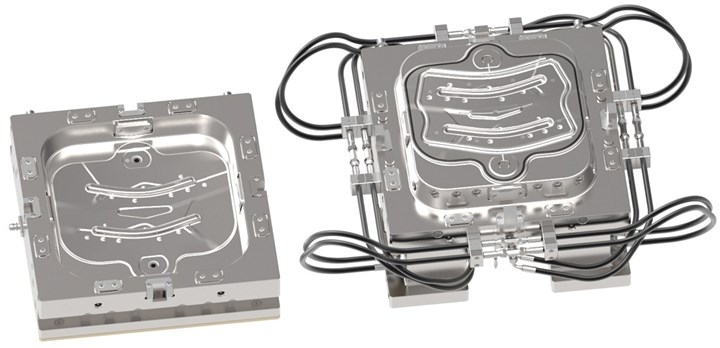

“It is only in the last decade that advanced, cost-effective engineered preform technologies have emerged, replacing the need for labor-intensive and accurate alignment of several preforms in an HP-RTM mold,” Andrea Castelnovo, technology and R&D manager at Cannon Tipos, says. “The innovative, near-net-shape dry preform developed through Coriolis’ AFP process, our steel mold, polished to a mirror finish, and high-pressure dosing machines and injection equipment helped realize a complex body-in-white [BIW] structural part for local reinforcement using a single preform in a fast and easy process with high productivity and sustainable costs.”

The AFP 2D dry preform is composed of an optimized fiber orientation of unidirectional (UD) nonwoven carbon fiber layers (280 grams/square meter – 8.25 ounces/square yard ply) with a 55% fiber volume fraction (FVF) — for optimized mechanical properties in the final part — and proprietary binding technology compatible with a fast-cure epoxy resin system, ready to be injected. The functionalization improves formability, permeability and trimming (3D waterjet) to obtain a net-shape contour and can achieve an overall reduction of up to 50% in scrap.

Cannon Tipos engineered the steel mold to withstand up to 120 bar (1,740 psi), thereby avoiding microporosity; to maintain constant temperature to within 2º to ensure optimal resin reaction with the hardener; minimize counterpressure during the infusion phase and maximize vacuum time to avoid washout and air bubbles; and due to the highly polished cavities, fully exploit the surface aesthetics of the final molded part obtainable with Coriolis’ preform technology.

The resulting BIW local structural part for series production is undergoing qualification trails. It has a 20-second takt time and displays equivalent mechanical performance when compared to incumbent application while offering up to 80% weight reduction.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.