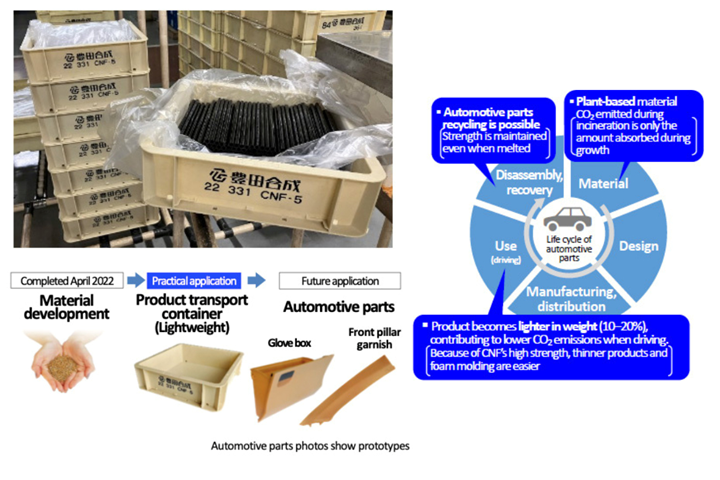

Toyoda Gosei develops nanocellulose fiber-reinforced plastics for automotive parts

Newly developed CNF-reinforced plastic used in product transport containers combines 20% CNF in a general-purpose polypropylene, aims to reduce CO2 over the lifecycle of components.

Toyoda Gosei Co. Ltd. (Kiyosu, Japan) has successfully applied a cellulose nanofiber (CNF)-reinforced plastic it developed for interior and exterior automotive products to make lightweight containers, which are currently being used in one of Toyoda’s manufacturing plants. The company says it will accumulate records on material use, with the goal of applying it to automotive parts in the future.

As one part of its efforts to reduce CO2 in the lifecycle of automotive parts, Toyoda Gosei is using its strengths in materials technology to incorporate various biomaterials such as CNF, a plant-based material with one-fifth the weight and five times the strength of steel. When mixed with recycled material from old polypropylene (PP) containers, CNF enables the production of lightweight, more recyclable parts. Specifically, the company says 6% weight reduction and a 6% reduction in CO2 over its entire lifecycle when compared to previous containers (the trial calculations were made assuming the containers will be used in product transport for four years). Moreover, when the material is reused, little strength is lost from heating and melting, making recycling in automotive components possible.

While the decline in impact resistance was a challenge, Toyoda Gosei says it leveraged its material mixing design and kneading technology and succeeded in raising the impact resistance to a level suitable for use in automotive parts.

Toyoda Gosei is one of 16 companies within Toyota Group. The company began as a rubber R&D division of Toyota Motor, becoming independent 70 ago. It has since grown to be a global company that researches, develops and manufactures high-quality automotive products such as cockpit modules, steering wheels and airbag systems for automakers globally. Toyoda Gosei creates a range of products across additional vertical markets, and is the only Toyota Group company specializing in plastic and rubber products, with operations in the Americas, China, Asia, Europe and Africa.

Related Content

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.