In a lot of industries, the aphorism “garbage in, garbage out” is a reliable maxim. If your inputs are of poor quality or little value, your final products will probably be as well. However, the automotive industry is turning that adage on its head by repurposing waste materials normally considered to have no use into functional, beautiful and valuable automotive parts for vehicles already on the road. In doing so, automotive companies are keeping materials out of landfills and waterways, providing jobs in distressed communities and giving farmers another income stream, all while reducing part weight and cost, stabilizing long-term material prices, and greening their vehicles. This is a good example of another saying: “One man’s trash is another man’s treasure.”

Ag waste

A lot of these repurposed waste materials are the agricultural by-products of food production. They’re generally the outer wrappings of crop plants, such as tomato skins from ketchup production or agave fiber from tequila production. These inedible wrappings (often from seeds) are the parts of plants that either will not compost or will not compost easily, and that have little or no utility as animal bedding. Their lack of utility causes these wrappings to accumulate in waste piles where they can prove a nuisance or, if ignored long enough, become a health and safety challenge. However, these fibrous outer wrappings are proving to be useful as natural fiber reinforcements for a variety of composites.

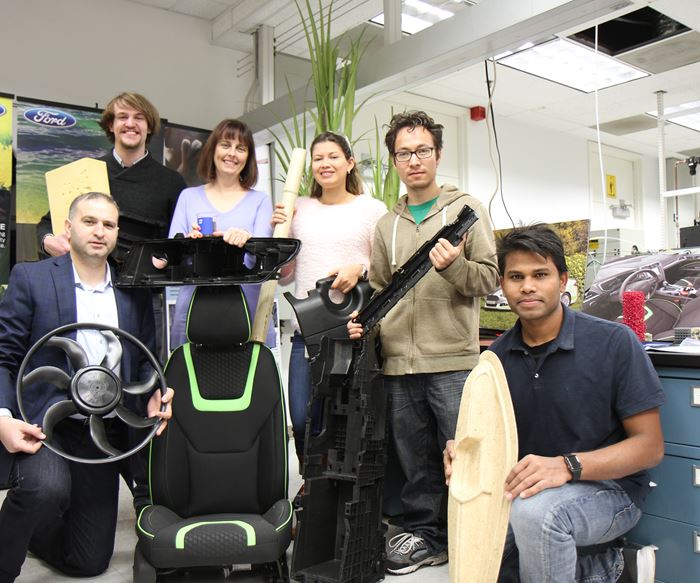

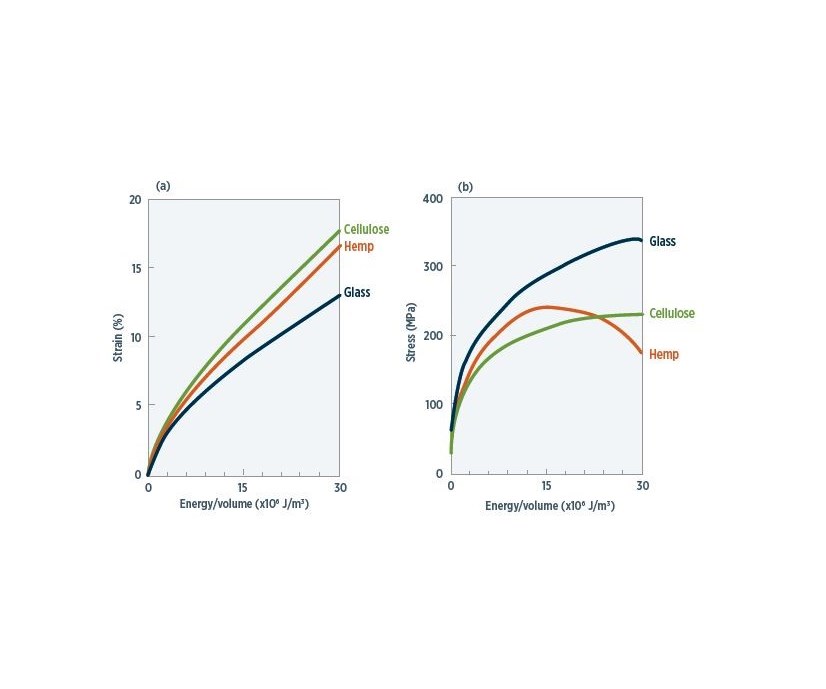

“People don’t understand that natural fibers are lightweight alternatives,” explains Debbie Mielewski, Ph.D., senior technical leader for sustainable materials research at Ford Motor Co. (Dearborn, MI, US). “They think that natural fibers are just for greening products and they look to far more costly materials like carbon fiber to cut pounds out of vehicles. At Ford, we believe we can remove tens-of-pounds [from a vehicle] using natural fibers. Not only are they an abundant local resource nearly everywhere, but our studies suggest they’re very good at absorbing impact energy, far outperforming glass [fiber]. Furthermore, natural fibers are far more recyclable than glass in that they tend to bend rather than break during processing like glass, so you don’t have to downcycle performance expectations for recycled materials. They’re also more flexible and bendable, and much more isotropic to design with than glass.”

It is no surprise that Ford has taken up the mantle that former DaimlerChrysler (DCX, now FCA US LLC, Auburn Hills, MI, US) carried in the early 2000s by using many natural fiber products in vehicle components. However, unlike DCX, which primarily worked with conventional bast-type fibers from inner bark/phloem from plants like kenaf, flax, sisal and jute, Ford has a knack for finding previously unused fibers that are equally effective. In fact, Mielewski says Ford’s vision is to use whatever natural resources are locally available near its production plants to reduce the costs and carbon footprint of shipping natural fibers around the world. For example, Ford might use agave fiber from tequila production in its Mexico facilities, bamboo fiber for Asian part production and tomato skins from ketchup production in North America. The automaker is even reportedly studying uses for dandelions, algae and the durable linen/cotton blend from retired currency.

Going nuts

Coconuts might seem an odd choice to reinforce automotive parts, but it turns out they’re plentiful between the Tropics of Cancer and Capricorn, and their properties are consistent from season to season, species to species, and soil to soil across that geographic region. Once coconut meat and milk are extracted at processing plants, the shell and its outer (coir-fiber) husk tend to accumulate in refuse mountains because villagers often lack the ability to dispose of them. Unfortunately, neither shell nor husk are edible, they have no animal or human bedding use, they don’t burn easily and they compost very slowly. On the positive side, at 250 µm, coir fiber’s diameter is significantly larger than that of most other natural and synthetic fibers, which contributes bending stiffness, strength and ductility to composites. Owing to the fiber’s high lignin content, it’s also inherently flame retardant, indigestible to insects and microbes (reducing odor) and is less prone to swelling under humid conditions.

In addition, coconut shells can be ground into a fine powder and used as a lighter, less abrasive replacement for mineral fillers like talc in plastics and composites. Ford, working with suppliers like Essentium Materials LLC (College Station, TX, US), has developed a number of applications for coir fiber and coconut shell powder starting with 2012 model year (MY) Ford Focus battery-electric vehicles (BEVs). In that case, coir was commingled with polypropylene (PP) fiber, then carded, needled and converted to a nonwoven felt. The felt was then die-cut, bonded to pressboard (itself containing recycled fibers), and sandwiched between recycled carpet on the A (face) side and polyester scrim on the B (reverse) side to produce a load floor/package shelf to cover (yet allow access to) onboard battery packs — all while providing a stable surface for consumer packages in the rear trunk. The porous felt core was light, stiff and absorbed sound on the vehicle interior.

The automaker next turned to ground coconut shells combined with rubber from shredded tires to produce a thermoplastic elastomer (TPE) that was injection molded into structural guards for 2013 MY Ford F-250 Super Duty pickups. The parts were lighter, less costly, and less abrasive on tooling than mineral-reinforced predecessors. In 2015, coconut powder was used for injection molded thermoplastic polyolefin (TPO) decklid appliqué brackets and side-door cladding on Ford Mustang sports cars in combination with shredded battery cases and magnesium-silica fibers from Milliken & Co. (Spartanburg, SC, US). This interesting combination reduced density, wall thickness, cycle time and cost.

Cereal part production

Cereal grain leavings are another group of agricultural waste that Ford has explored in reinforced plastics and composites. First used in 2010 on Ford Flex cross-over utility vehicles (CUVs), wheat straw replaced talc in injection molded PP quarter-trim bins. More wheat straw is produced in Ford’s home state of Michigan and in the Western Canadian provinces than can realistically be sold as animal bedding or composted in the region’s cold, wet soils. By using wheat straw to reinforce car parts, farmers gained additional income and avoided sending plant material to landfills, while the automaker improved dimensional stability of parts vs. unfilled versions and reduced part mass with a greener alternative than talc.

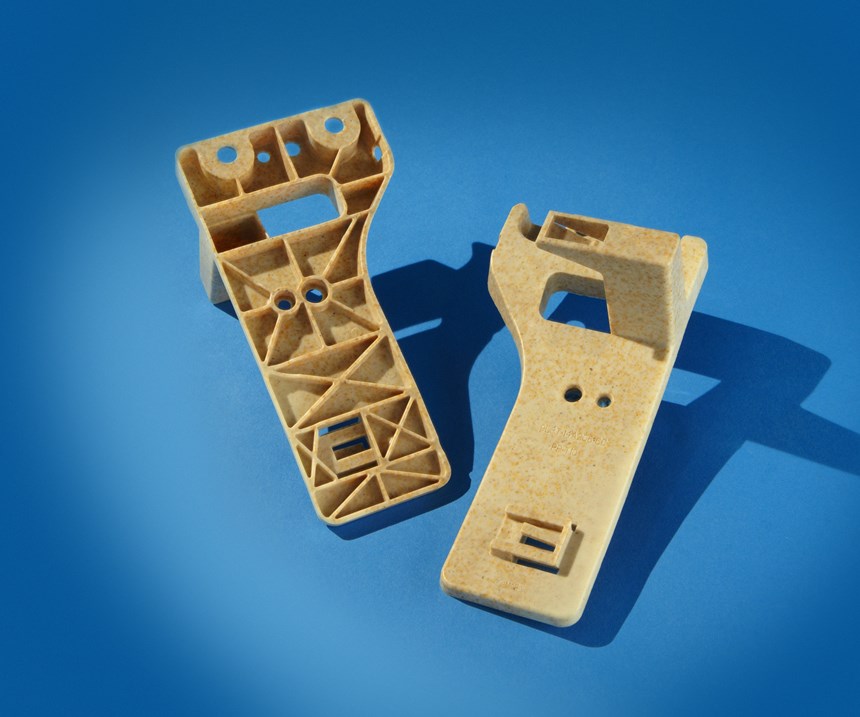

Rice hulls from the US Gulf Coast were another reinforcement Ford experimented with on high-volume 2014 MY F-Series pickups. Normally landfilled after extracting from fast-growing rice crops, the hulls were combined with polypropylene (PP) — itself containing 25% post-consumer recyclate (PCR) — to form injection molded electrical cowl brackets that are renewable and recyclable. Although this first application was cost and weight neutral, the novel reinforcement was environmentally beneficial and brought additional revenue to farmers.

Wood you believe trees?

Ironically, one successful environmental effort — to reduce US paper usage — has led to economic challenges for pulp and paper companies that now are searching for new markets for cellulose fiber, a by-product of lumber operations in sustainably harvested forests. In turn, that’s led to another non-traditional natural fiber reinforcement that Ford is exploring — at both the macro and the nano level — to replace glass fibers. The first automotive application of cellulose fiber was console armrests on 2013 MY Lincoln MKX luxury CUVs that were injection molded with 20% cellulose-reinforced PP. The parts were cost neutral, 6% lighter, less abrasive on tooling, and reduced injection molding energy requirements by 10% thanks to faster molding cycles and lower molding temperatures. Ford also estimated that, versus glass fiber/PP, the greener parts reduced CO2 emissions by more than 11% and would save 9,464 liters of fuel over the life of each vehicle.

Another tree product that has found its way into vehicle interiors is cork — the inner bark of cork oaks that is harvested once a decade and is most commonly found stoppering bottles of wine. In this case, Hyundai Motor Group (Seoul, South Korea) is using cork-wood films to replace multilayer hardwood veneers (which are costly, labor-intensive to produce and non-renewable) on door-trim panels for 2017 MY Hyundai Azera (called Grandeur in Asia) midsize hybrid-electric sedans. By eliminating the 20-step process normally required to produce hardwood veneers, the simplified insert-molded cork films plus acrylonitrile butadiene styrene (ABS) produces parts that are 24% lighter and 65% less costly. Furthermore, cork’s honeycomb structure provides elasticity, thermal insulation and sound damping, in addition to good looks. The automaker indicates that its researchers are also considering cork’s use as a possible noise/vibration/harshness (NVH) material.

And in the 2018 SPE Automotive Innovation Awards Competition, Ford nominated what it described as the industry’s first use of a hybrid composite combining long-fiber(glass) thermoplastic (LFT) polypropylene with cellulose (in post-industrial recyclate resin). The center console components were produced via injection molding.

Rockin’ fillers

Another interesting Hyundai application involved the use of the mineral scoria — a low-density volcanic rock similar to pumice, but higher in density — that tends to form tall cones around volcanic sites. Its porous structure (created as gas escapes cooling lava) provides high surface area and strength vs. weight, plus it is available in a range of colors — from dark brown to red, purple and black. Scoria is typically used as a landscaping stone, in drainage works, in gas barbeque grills, as a high-temperature insulation, to improve traction on icy roads and around oil wells to keep heavy-trucks from sinking into mud. Perhaps its most famous use was on Easter Island, where the Rapanui people used it to form the topknots and some bodies of their renowned moai statues. Hyundai extended scoria’s use to automotive parts on the 2011 MY Kia Pride subcompacts and Optima midsize sedans, plus Hyundai Elantra midsize sedans. In this case, crushed scoria was combined with polyethylene terephthalate (PET) fiber pile and glass microspheres in a PP compound that was injection molded to produce textured pillar trim panels for vehicle interiors. The unusual filler combination creates a surface with tiny flecks of color and eliminated the need to paint or fabric-wrap the molded trim panels, reducing mass 10% (vs. talc) and direct costs 50%, while eliminating the cost of fabric wrapping and the cost and environmental burden of paint.

“We developed (these) novel materials to make an imitation cloth-feeling composite,” notes Daesik Kim, Ph.D., Hyundai part leader of the plastic materials development team. “The combination of volcanic rock and PET pile was the most efficient approach. PET pile alone was too costly. The volcanic rock was low in price and had good processability and durability. When we applied common minerals like talc and mica, it didn’t work at all.

Waste not, want not

Automakers are turning to other non-traditional waste products to make car parts, too. An intriguing closed-loop recycling application that General Motors Co. (GM, Detroit) used on 2011 MY Chevrolet Volt extended-range hybrid-electric vehicles (HEVs) helped with clean-up efforts in the Gulf of Mexico after the 2010 Deep-Water Horizon oil spill. First, companies collected post-industrial recyclate (PIR) automotive packaging waste made up of PP and polyethylene (PE). That material got another life when it was used to produce absorbent materials for oil-containment booms, which help prevent oil spills from spreading and allow the mess to be mopped up from bodies of water. After cleaning up the oil spill, petroleum products were removed from the absorbent materials, which were then given yet another life when they were combined with equal parts styrene butadiene (SBR) rubber from shredded tires, more packaging aids from GM facilities and post-consumer recyclate (PCR) PE bottles. The resulting compound was injection molded into air-baffle components for Volt HEVs. The automaker described the application as a way for automotive engineers to help improve the response to Gulf cleanup efforts, conserve materials and support local communities.

GM also spearheaded another closed-loop recycling program that turned the problem of lead-contaminated drinking water in Flint, MI, US, into an opportunity that brought jobs to disadvantaged communities while repurposing valuable waste consumer packaging back into car parts, assembly-plant goods and clothing for the homeless. To date, very few of the lead-contaminated water pipes have been replaced in Flint, so residents still rely primarily on bottled water, which has created a waste problem with empty PET bottles. Led by John Bradburn, now retired project leader and global manager of waste reduction at GM, a multi-stakeholder supply chain was assembled to collect water bottles from Flint’s municipal recycling program as well as from GM’s assembly plants, engineering centers and administrative facilities throughout Michigan. These bottles were recycled into PET fiber, which, in turn, was converted into nonwoven fleece. The fleece was then used to produce insulation for the B-side of 15% glass fiber-reinforced polyamide 6/6 (PA6/6) engine manifold covers on 2017 MY Chevrolet Equinox sport-utility vehicles (SUVs). The fleece also was used by at-risk individuals in a Flint-based jobs training program called St. Luke’s N.E.W. Life Center to produce large air filters for 10 GM manufacturing plants. Still another use for the fleece was as insulation for coats sewn by formerly homeless women employed by the Detroit-based Empowerment Plan.

There is a water-bottle recycling program under way at Ford as well. Although not as ambitious as GM’s, PET water bottles from Ford’s Research & Engineering Center, local community materials-recovery facilities (MRFs) and Ford’s own post-industrial scrap are recycled and spun into PET fiber, which in turn is used to weave durable REPREVE seat fabrics. The 100% PCR/PIR fabric debuted on 2012 MY Ford Focus BEVs and expanded in 2015 into Ford F-150 pickups and 2016 MY Ford Explorer SUVs, supporting the automaker’s goal of translating the fabric across all its vehicles. With just the F-150 platform, use of the 100% recycled fabric diverts 5 million water bottles/year from landfills. Further, what fiber and fabric Ford doesn’t use is converted for use in clothing, tote bags and socks.

Where do automakers think this waste-repurposing work could ultimately go? Mielewski says there are more ideas out there than there are hours in a day and staff to investigate. Corporations and trade associations are starting to see the opportunities that partnering with the automotive industry can bring and are reaching out to OEMs with ideas of their own. For example, a project at Ford, where researchers are trying to sequester the greenhouse gas CO2 to produce automotive parts, happened because of involvement by and funding from the Canadian Carbonization Research Association (CCRA, Hamilton, ON, Canada). Ford also has been approached by other organizations, including the California Almond Board (Modesto, CA, US) to explore the use of ground almond shells. “The sheer number of materials that could be used to make more sustainable car parts far exceeds our ability to research them,” Mielewski muses. “And that doesn’t even consider what we could do with blends that might combine several different kinds of material, like hybrids of natural fibers or natural resins with fibers,” she adds. “However, what we’re trying to do [at Ford] right now is to remove every reason not to make the move to more sustainable materials. If you’re serious about lightweighting, for example, we’ve got materials ready to go that have already been tested and proven out.”

Related Content

Belzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreToray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

Read MoreWomen in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreAMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)