Composites: A Band-Aid or a Fix?

Having spent many years developing composite materials, applications, and solutions for industry issues, I believe we have come to a crossroads. We all too often take quick, short-term actions to address our tasks and issues at hand. I characterize these as Band-Aid solutions. For example, sending government represe

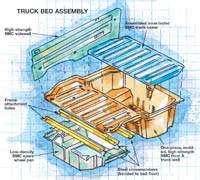

So how do we in the composites industry trade Band-Aids for solutions? This may sound obvious: We need to make composites the mainstream solution in the all markets in which our industry participates. For many applications, composite solutions still are a secondary or a parallel effort that might replace metal or other material developments. For many years, that was the case for the composite pickup truck box. Beginning the 1980s, many OEMs tried to make composite boxes a commercial reality and failed. Why? The composite bed, typically, was optional equipment and a more expensive option as well. A steel box was standard equipment. The one exception is the 2006 Honda Ridgeline. Honda embraced composites as the only solution for its vehicle and actively promoted this feature in its sales and marketing efforts. The SMC composite box, with its integrated storage system, became the design centerpiece of the vehicle. The Ridgeline composite pickup box continues to be a viable design and marketing solution for Honda.

How do we apply this object lesson in the future? In the transportation segment, I believe OEMs need to accept improved performance, light weight, and lower investment costs in composite processes as the preferred basis for vehicle development. All too often, composite solutions are shelved because of their perceived costs rather than their true overall cost and performance benefits. Newer, lighter weight, composite-intensive vehicles should not be classified as less safe than older, heavier steel-based products. Safety can be inherently designed in with higher performing composites solutions if designers start with a clean sheet instead of trying to force-fit composites — at the 11th hour — into a design developed originally for steel. What about higher costs? Ask a car dealer with a fleet of heavy, gas guzzling vehicles sitting on his/her lot about costs vs. the potential to sell a better performing product.

We need to change the mindset of our customers and product end users so they believe that composites are the right choice. Better designs and engineering, all-around cooperative efforts, and successful application developments will give us the momentum to rightfully position composites as the lightest material with the highest energy absorption, the lowest lifecycle cost, and the greatest design freedom.

We are facing an unprecedented opportunity for the growth and vitality of our industry. The energy crisis and rapid increase in the cost of steel both present us with a tremendous opportunity to bring our composite solutions to the forefront. In fact, new composite applications will come from the energy segment itself. Ask an oil producer if he/she would prefer a high-performance composite pipe that solves chemical, heat, and durability issues and that can be delivered in months vs. waiting years to obtain higher cost, heavier steel pipe with far shorter useful life and its tremendous production lead times.

Have we arrived at a point where the composites industry can take the lead in materials and application development in all segments? Probably not. There are, of course, many factors that influence our industry, economy and society over which we have little control. But as we stand at the crossroads, we need to focus on getting there. We'll succeed much more often if we make it an imperative to pursue complete composite solutions, settling for nothing less than composites as the preferred, long-term fix for our industry's- and greater society's- problems. To do that, we have to leave behind forever our Band-Aid thinking. That road leads nowhere.

Frederick S. Deans has more than 39 years of manufacturing, sales and marketing, and product development experience, with the past 23 years spent in the composites industry. A member of SPE’s Composites and Automotive Divisions Board of Directors, Deans has been a planning member of the SPE Automotive Composites Conference & Exhibition and Composites on the Move programs. Currently, he is a principal of Allied Composite Technologies LLC (Rochester Hills, Mich.), a business-development enterprise that specializes in materials, application development and validation, manufacturing, and new product and market introduction. Deans can be contacted at fdeans@alliedcomptech.com.

Related Content

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreSMC BMC Design Award 2024 winners showcase projects at JEC World

Awards ceremony to be held on March 6th will recognize the top three selected SMC and BMC designs submitted by European design students and young design professionals.

Read MoreComposite materials, design enable challenging Corvette exterior components

General Motors and partners Premix-Hadlock and Albar cite creative engineering and a move toward pigmented sheet molding compound (SMC) to produce cosmetic components that met strict thermal requirements.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

Inside-the-box thinking pays off for Honda

New Ridgeline pickup features innovative composite box with first-ever molded-in trunk.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)