CW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

We editors here at CW see a lot of what the composites industry has to offer. We go to trade shows, we visit companies, we talk to people, we listen, we take pictures, we take notes, we research, we write. And each of us is expected to be well-versed enough about composites to write intelligently about almost every aspect of the industry: Resin, fiber, tooling, processes, software, machining systems, structures, aircraft, cars, trucks, boats, wind blades, pipe, surfboards, golf clubs, satellites, manhole covers . . . you get the idea.

Given this, we are launching this year a new report (annual, I hope), called CW Ideas in Action. Why “in Action”? Because anybody can think of a new way to do something. But ideas are just ideas until someone does the hard work of putting them into action and seeing practical, real-world results. That’s really the only thing that counts. So this year, I’ve asked each editor to look back on the year that was (2015) and offer her/his opinion on the most promising, innovative or just plain interesting composites-related idea or concept that is finding its way into useful form. The result is below, and I think you’ll find our assessments as diverse and thought-provoking as the people who wrote them. Let us know what you think, and have a good 2016.

— Jeff Sloan, Editor-in-Chief; jeff@compositesworld.com

3D printing adds an exciting new dimension

By Heather Caliendo, CW Managing Editor – Electronic Products; hcaliendo@gardnerweb.com

I’ve watched this year as 3D printing has moved from a relative curiosity to what looks increasingly like a serious contender for real-world industrial applications. Here are two of the many reasons why:

Arevo Labs (Santa Clara, CA, US) has introduced a scalable Robot-based Additive Manufacturing Platform (RAMP) for industrial fabrication of 3D-printed composite parts. The first-of-its-kind offering consists of a standard commercially available robot, composite deposition end-effector hardware and a comprehensive software suite. Arevo’s offering is tailored to ABB’s (Auburn Hills, MI, US) smallest 6-axis robot, the IRB 120, but the scalable software can support larger ABB robots. The additive end-effector hardware consists of a deposition head with advanced thermal-management technology for processing continuous or chopped carbon fiber-reinforced thermoplastics. The platform’s multi-axis toolpaths enable production-quality parts constructed with 3D surfaces in variable orientations.

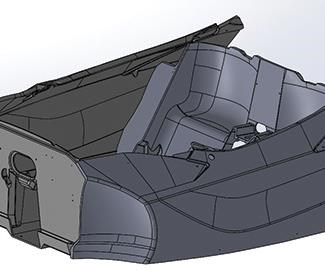

Local Motors (Chandler, AZ, US) got the auto industry’s attention by using the Big Area Additive Manufacturing (BAAM) machine, built by Cincinnati Inc. (Harrison, OH, US) with help from Oak Ridge National Laboratory (ORNL, Oak Ridge, TN, US), to build the world’s first 3D printed car (first photo in series at left) at the IMTS show last year (see "Additive manufacturing: Can you print a car?" under “Editor's Picks,” at top right). Local Motors is now moving into intensive testing and development that will culminate in a road-ready series of cars, under the name LM3D, built using direct digital manufacturing (DDM). About 70% of the LM3D will be 3D-printed, including body panels and chassis, which will be carbon fiber-reinforced ABS plastic. SABIC (Riyadh, Saudi Arabia) provides the materials used to build the LM3D and Siemens (Munich, Germany) developed the software.

Industrial, automotive … we’re well past the novelty stage.

Getting past lifecycle cost to cost parity

By Sara Black, CW Technical Editor; sara@compositesworld.com

I see suppliers who are, finally, finding ways to optimize products and processes to create a viable value proposition that puts composites at or very near cost parity with conventional materials. Instead of touting composites’ benefits to justify the greater material cost, companies are now increasingly able to say, “This composite product costs about the same as [insert steel, aluminum, or…] and provides incredible benefits.” Some great examples come to mind:

The first is a basalt fiber-reinforced rebar product from Neuvokas (Ahmeek, MI, US), which CEO Erik Kiilunen says costs the same as steel. The rebar is intended for flat concrete slabs that require no special shapes, stirrups or onsite bending.

Another is a new cooperative venture between Wabash National (Lafayette, IN, US) and Structural Composites (Melbourne, FL, US), under which Wabash will manufacture a new composite refrigerated truck trailer that is close to cost parity with aluminum (the technology was on display at the recent CAMX 2015 show, and a CAMX award candidate). Low-cost polyester resin is tweaked for better performance, using urethane, and low-cost, off-the-shelf structural preforms are combined with a thin laminate in a patent-pending assembly line that delivers a lighter-weight yet still durable solution. Wabash believes in the concept to the extent that it is building a new production line to produce the panels.

If composites are to expand into automotive platforms, then this cost parity trend is an absolute necessity. For many years, I’ve sat in keynote sessions at the Society of Plastics Engineers (SPE) Automotive Composites Conference and Exhibition (ACCE) and heard OEMs say that the value proposition isn’t there — yet — for composites. But this year, a “yes, it is” example came to light. Automotive specialist Antony Dodworth, managing director at Bright Light Structures (Peterborough, UK), exhibited an all-carbon fiber composite chassis tub, using recycled carbon fiber, (see photo #2 and #3, at left) for British kit-car maker Zenos (Norfolk, UK). The five-piece tub can be made quickly (less than 15 minutes) and features a very inexpensive plastic core that’s crushable, enabling thermoforming of the tub elements. The Zenos E10 car is not a fancy supercar but an affordable (kits from £24,995) sports convertible that costs less than just about any comparable sports car on the market today. Cost parity — hope that trend continues.

Crossing the thermoplastic/thermoset divide

By Ginger Gardiner, CW Senior Editor; ginger@compositesworld.com

As composites move into high-production industries, there is a need for shorter molding cycles and recyclability. In the automotive sector, for example, 85% by weight of end-of-life vehicles in the European Union must be reusable or recyclable as of Jan. 1, this year. Thermosets crosslink as they cure, offering high structural performance and lighter weight. They also offer the low viscosity necessary to thoroughly wet out fiber reinforcements — essential for those high mechanical properties. Thermoplastics can be processed very quickly but their high viscosity, low temperature resistance and moisture uptake at the amorphous, engineering polymer end of the spectrum cause problems. At the high-performance end, the issues are control of cool down for the required crystalline structure and high cost. What the industry needed was resin systems that combined the positives of each but avoided the negatives.

In 2014, Arkema (Colombes, France and King of Prussia, PA, US) launched Elium reactive liquid acrylic thermoplastic resins, which boast low viscosity (100 cps) at room temperature, enabling resin injection without heating in resin transfer molding (RTM), high-pressure RTM (HP-RTM) and infusion. Elium composites attain mechanical properties comparable to epoxy without post-curing but boost toughness by 50% and are recyclable, weldable and thermoformable at 200-220°C. Cure times range from 20 minutes to a few hours at room temperature, but drop to 30-120 seconds at temperatures above 100°C. Recycling has already been demonstrated and water pickup is only 0.5% vs. polyamide’s typical 5-10%.

Also launched in 2014 is Connora Technologies’ (Hayward, CA, US) Recyclamine hardener, which applies photoresist chemistry (now common in microchips) to epoxies, enabling a cleavable bond to be programmed into the resin so that, under specific conditions (e.g., pH level or light) crosslinks can be broken, leaving recyclable thermoplastic molecules. Connora’s technology is applicable to all types of epoxies; it does not diminish their processability or properties, but makes them recyclable, a claim which Connora has demonstrated (see photo #4 at left, and for more information, click on "Connora Technologies makes epoxy truly recyclable," under “Editor's Picks,” at top right).

Most recently, Cornerstone Research Group (Dayton, OH, US) introduced MG Resins, based on a novel polymer system, which cure to a thermoplastic state below 110°C and convert to a thermoset above 180°C, offering high-temperature resistance like that of a polyimide (service temperature of 300-450°C) as well as ultra-low flammability, heat release and smoke release, yet are similar to two-part epoxy resins in processability and cost (for additional insight, see "New low-cost, high-temp resins" under “Editor's Picks”).

The products listed here, and those that will inevitably follow, hold an amazing amount of promise. I hope our industry responds by working with these and other suppliers to convert this potential into real success stories CW can write about in the near future.

Wise engineers still put pencils to paper

By Mike Musselman, CW Managing Editor; mike@compositesworld.com

I’m 66 years old. So for me (and CW), it’s still Web site, not website. Yes, I’m Old School, not old school. But don’t get me wrong. I’m no naysayer when it comes to technology. Digital tools, particularly in the realm of design and simulation, are on my thumbs-up list (I do love my Mac, and I’ve been almost paper-free for a decade). I’ve watched CAD/CAM/CAE and FEA/simulation software evolve into powerful means to circumvent costly, time-consuming guesswork and iterative physical testing, and make composites more competitive in some unforgiving marketplaces.

That’s why I was surprised and … well, touched, when a young fellow by the name of Collin Petersen, lead design engineer at Janicki Industries (Sedro-Woolley, WA, US), wrote a guest column for CW recently titled, “Hybrid analysis: Making the most of FEA by leveraging traditional analysis.” In it, Petersen gave examples for which FEA and related digital tools were used to model a mandrel prototype (pictured here in photo #5 at left), but because the customer’s desired factor of safety allowed it, he was able not only to simplify the FE analysis but also to tackle portions of the design — the mandrel spindle, welds and fastener joints, which are quite difficult and, therefore, very time-consuming to model with FE tools — using simple hand calculations laid out in classic mechanical design textbooks.

Implementing such techniques, Petersen quips, “can give valuable context and verification to go along with all of those colorful FEA stress plots.” And this practical decision not only saved much time but also, he claims, increased confidence in the tool outcome. (For the whole story, see the article matching his title under "Editor's Picks.")

For me, and I hope for others, it was an epiphany. Those engineers I watched on black-and-white TV send the first men to Earth’s moon back in the 1960s? They did it using formulas from books and slide rules, with pencil and paper. Those who today use the digital tools but also know their way around those formulas from dusty old books? I believe they’ll have the edge.

This business — and it is a business — is still about people, people who have to make intelligent decisions. Something software can’t do for us. At least, not yet.

With access to all the tools, digital and manual, and starry-eyed fascination with and overdependence on none, composites engineers who make wise choices, and take practical actions that balance performance, cost, resources and time will be able to produce products that truly meet customers’ needs in the real world in which we live.

The tools will be as useful as the educated people who use them.

Turning the corner toward commercial CNTs

By Jeff Sloan, CW Editor-in-Chief; jeff@compositesworld.com

For several years, there’s been a difficult-to-bridge gap between making carbon nanotubes (CNTs), and making them work. Lab research has demonstrated massive mechanical and conductivity benefits to be derived from composite structures that make use of CNTs. But the trick has been how to make them functional and cost-effective in a resin matrix or fiber reinforcement. The main problem has been agglomeration — the tendency of CNTs in solution (resin matrix) to aggregate and clump, which negates their benefits in the final part or structure. There have been some successes: Zyvex Technologies (Columbus, OH, US) has commercialized a full line of CNT-based additives. Another supplier, Nanocomp Technologies (Merrimack, NH, US), is fabricating CNT sheets, tapes and yarns that have been integrated into a variety of composite layups in anti-ballistic, aerospace and other applications.

In 2015, however, I saw two companies stake a claim in the market with technologies that could take CNTs to a new level of functionality, signaling that CNTs have likely turned the corner.

The first is N12 Technologies (Cambridge, MA, US), a spinoff from the Massachusetts Institute of Technology (MIT, Cambridge). N12’s technology focuses on vertical aligned CNTs (VACNTs), which are “grown” in “forests” on a substrate surface in a furnace-based process and then placed between prepreg plies to provide the interlaminar properties that help minimize cracks and delamination. Tests have shown >30% improvement in interlaminar shear stress values. N12 also has demonstrated that VACNTs can increase fatigue life by 100%.

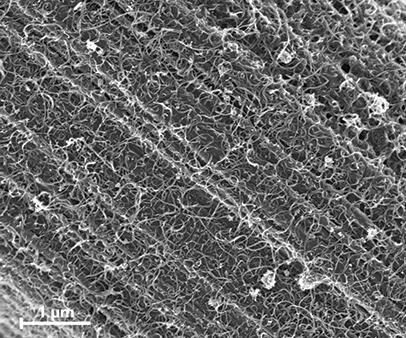

The second, SP Nano Ltd. (Yavne, Israel), has developed SP1, a thermally stable protein that tightly binds to CNTs to form a stable SP1/CNT complex (photo #6, at left). SP1/CNT can be applied as a sizing-like coating to dry carbon fiber at loadings of 0.3-0.4 wt-%. SP Nano tested this material, wet-laid and autoclave-cured, using a phenolic resin, and compared the results to those from the same test conducted on a carbon fiber/phenolic without the SP1/CNT coating. The interlaminar shear strength of the SP1/CNT composite was 47% greater than that of the non-SP1/CNT composite. Moreover, through-thickness tensile strength tests demonstrated a 176% increase in the SP1/CNT composite.

Also, keep an eye on two other players in the nanosphere: OCSiAl (Luxembourg), which makes cost-efficient single-wall carbon nanotubes; and Haydale Ltd. (Ammanford, UK), which uses plasma treatment to functionalize CNTs in resin matrix.

Nanomaterials are here to stay, and these CNT offerings might just be the tools the composites industry needs to make them work.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreDesigning an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

Read MoreRead Next

Hybrid analysis: Making the most of FEA by leveraging traditional analysis

CW guest columinst Collin Petersen (Janicki Industries, Sedro-Woolley, WA, US) suggests the use of more traditional analysis methods, where it is sensible to do so, making your finite element analysis (FEA) significantly simpler in the process.

Read MoreAdditive manufacturing: Can you print a car?

Collaborative demonstration dispels doubt about 3D printing’s disruptive potential for direct-to-digital manufacturing of just about anything BIG.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)