The digital thread: Transformation to automation

Dr. Leslie Cohen traces the “digital thread” on which automation of composites fabrication processes depends.

Let me offer you a simple definition of sales, marketing and new business development: If there is nothing to ship tomorrow, you failed. If there is no backlog, you failed. If you go out of business because there were no orders, you failed. If you’re not competitive, you have failed.

First, you must be able to recognize your company’s identity to help you relate to what you are about to read here. The operative words are prime and responsible. As before, everyone works for the prime, but under the new model that has emerged with the 787 Dreamliner and the Airbus 350 XWB, the lower-level suppliers have new and different responsibilities: Tier I suppliers have design and build responsibilities, and Tier II suppliers (the next level down) often have responsibility for subsections and design build. Lower down the line, the familiar build-to-print fabricator is now a Tier III. Down further in the stack, the commodity supplier and the material supplier, such as the prepreg supplier, have moved down to Tier IV.

In these times of change, the key to prospering is the ability to adapt. The smart ones change before they have to. The lucky ones manage to scramble and adjust when push comes to shove. The rest become history. Aerospace is the traditional market for advanced composites, where the requirements are performance-driven. In recent years, the industry has demanded — and the suppliers have responded with — lower-cost manufacturing practices and procedures, and the word affordability now has teeth. If you cannot make the affordability aspect of the business case for composites, the probability of implementation to production is drastically reduced.

For the past 20 years, we have been migrating from manual fabrication methods to automation. Automation has been the key to reduce touch labor and drive to affordability, be it metal or composite. Touch labor is expensive and produces lower quality than automated or mechanized manufacturing. Many have said to me, “We are too small to invest. We must simply keep the cost of labor down,” and a lot of other such comments. The fact of the matter is that there’s not much future in this strategy. If you are a lower tier contractor, you need to find a home in this global world.

As we design for manufacture, with automation embedded up front, we will see performance, quality and affordability as a result. We do not want to go in the opposite direction. During the past decade, several prime contractors were either acquired or converted to subcontractor status. It is not just consolidation (as we saw when the prepreg community consolidated from seven or more quality prepreggers to two). It is obsolescence as a result of missing the market — trying to sell what is not wanted. Those of you familiar with downtown Pittsburgh remember well how the whole south side of that city was one large steel mill populated by companies like Carnegie and J&L. Now we have a shopping mall and food courts. If you do not pay attention to the business case, bad things can happen. Automate, emigrate or evaporate.

We at HITCO automated: two automated tape laying machines, seven autoclaves, with two more on the way. We put in a new cleanroom, enhanced with CNC high-precision trimming and drilling machines, four large NDT tanks and much more. With this automated capacity and these robust processes, we captured top-line growth programs, both civil and military.

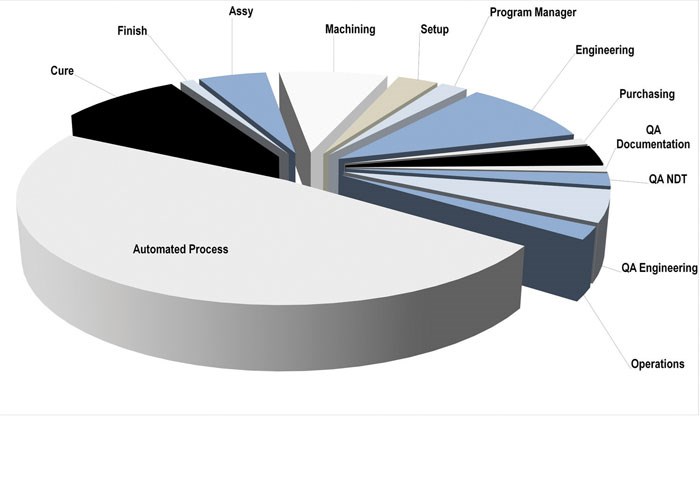

But this is only a small part of the journey and only a portion of the message. Yes, automate, emigrate or evaporate. That is certain. But there is a much deeper aspect of the competitive edge in using composites. That is the implementation of the “digital thread” concept. The pie chart on p. 11 shows the breakdown for automated fabrication and assembly of a typical, modern complex aerostructure subsystem using slit tape, based on several studies. About half of the recurring cost is tied up in the automation function and the other half is tied up in people: engineering surveillance, inspection, tool setup, quality assurance and other processes. These people have not changed since I came to the industry. It’s not that they are not required functionally; it’s that most of what they do is not done digitally. It’s touch labor and analog. And that drives up cost, increases cycle time, decreases quality and hurts the company’s ability to capture both affordability and performance, in both the short and the long-term.

The digital thread goes from conceptual design through detail design and into manufacturing and MRO. That same digital thread that starts with design engineers is used for the entire lifecycle of the airplane. Just as we made the journey from wooden aircraft to aluminum and now composites, I am sure our community will make this digital journey to capture both affordability and performance for composite aerostructures. The front end of the process — trade studies, structural concepts, loads, design for manufacturing — is no longer done with pencil and slide rule, but it uses a spectrum of digital tools that rapidly produce concepts using PC-based codes. The database is completely digital. The digits are passed to finite element codes that generate models using 3-D solids that permit complete visualization of the design concepts, construction details, manufacturing processes and flow. As we move through the process, we can transform the digits’ conceptual design rapidly to create a simulation of automated manufacturing, such as tape width, machine protocols, lay-down rates and the path of the slit tape. The simulation quickly flags areas of the concept design that are not possible to manufacture.

But we no sooner made the digital journey than we went right back to paper for part production and documentation, including the quality “travelers” that go along with each part. Now, let’s be clear: Quality assurance is paramount to making hardware. It’s mandatory. But the real questions are: How efficiently do you do it? What are the technologies that allow one to validate that conforming hardware has been made? What new technologies should be developed? Suffice it to say that the overarching strategy should include complete integration of the digital thread right through quality assurance. That famous quality chop — the official Seal of Permission to proceed and the supporting ink pad and paper that is stamped — is, in the world of the digital thread, “road kill.” It has been leaned out by digits that do not weigh anything and are understood by any recipient, independent of where they are in the world.

So, in our new world, where we have taken the automation journey and implemented a strategy, rather than emigrating or evaporating, we must now harness and leverage the digital thread to drive down both the nonrecurring and recurring cost of the composite hardware.

Take these digits from inception all the way through MRO. By doing so, the fullest potential of the performance and the widest possible use of our composite materials and structures discipline will be captured for the benefit of mankind.

Editor’s note: This article is excerpted from Dr. Cohen’s keynote address, given at the SAMPE Europe gathering in Paris on April 12, 2010, with associated visual materials.

Related Content

Busch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

Read MorePlataine unveils AI-based autoclave scheduling optimization tool

The Autoclave Scheduler is designed to increase autoclave throughput, save operational costs and energy, and contribute to sustainable composite manufacturing.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreIndustrial composite autoclaves feature advanced control, turnkey options

CAMX 2024: Designed and built with safety and durability in mind, Akarmark delivers complete curing autoclave systems for a variety of applications.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More