Hydrostatic membrane consolidation: Skin-stringer panels in 60 minutes

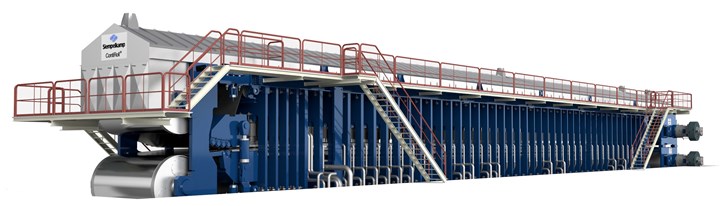

Airbus and Siempelkamp demonstrate press process as alternative to thermoplastic welding, aimed to enable rate 100 aircraft and future mobility manufacturing.

Share

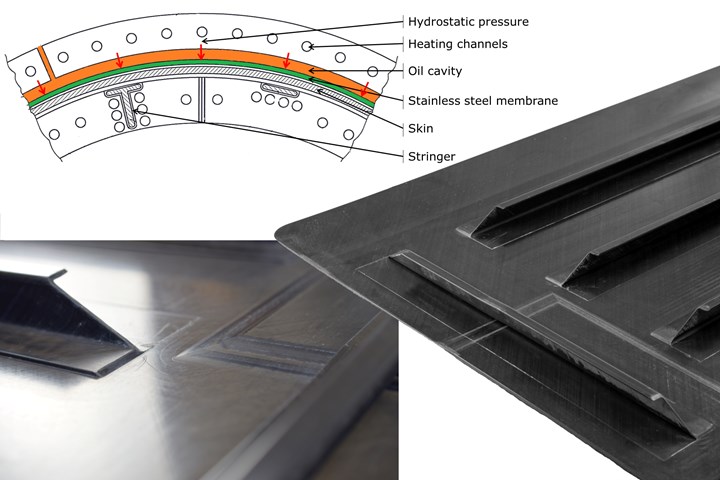

Consolidated skin-stringer panel

This 1.2- x 0.7-meter carbon fiber/PAEK challenge panel features prefabricated stringers fused to a skin that was simultaneously consolidated using a solid lower tool with cavities for stringers and a thin metal membrane as upper tool with heated oil behind it to exert hydrostatic pressure during a single, short press cycle. Photo Credit, all images: Airbus, CTC, Siempelkamp

Within Germany’s Federal Aviation Research Programme V-3 (LuFoV-3), the TRumpf project — short for “highly-integrated thermoplastic fuselage” (or rumpf in German) — is designed to develop autoclave-free consolidation of thermoplastic prepreg laminates as an enabler for aircraft fuselage manufacturing. CW has already reported on one of many such TRumpf subprograms and partners in the article, “DLR Institute of Structures and Design increases maturity of thermoplastic composite fuselage structures,” where the German Aerospace Center (DLR) Institute of Structures and Design (Stuttgart) demonstrated its vacuum consolidation technique (VCT). DLR used VCT to produce curved skins with integrated stringers combined with resistance welding for attaching frames and cleats. But thermoplastic composite welding also has issues, and thus, a variety of approaches are being developed within TRumpf.

This article discusses a subproject led by Airbus Operations in Hamburg and Stade in collaboration with the Airbus subsidiary Composites Technology Center (CTC, Stade, Germany) and press production line supplier Siempelkamp (Krefeld, Germany) to design an alternative manufacturing process that replaces welded stringers with a single-step heated press technique that consolidates skins while integrating stringers, clips and potentially even frames.

“Airbus is developing technologies for the next aircraft generations,” explains Alexei Vichniakov, composites technology development for Airbus Operations in Hamburg. His current focus is on thermoplastic technologies for the Fuselage of Tomorrow. “Today’s aircraft use aluminum and thermoset composites, which require drilling and fasteners for assembly, including nine manufacturing steps required for the fastening process. But thermoplastic composites offer the ability to simply reheat and reform the pre-manufactured material [which is shelf stable and solid], enabling very quick consolidation cycles and the elimination of cold storage and cleanrooms currently required for thermoset prepreg layups.”

He notes that thermoplastic composites can also be fused together by applying pressure and heat, which enables dustless joining and low-cost manufacturing compared to riveting. “This is a significant enabler for future manufacturing,” says Vichniakov, “where we can pre-install systems and equipment into very complex modules, which can then be joined together cleanly. However, we don’t know which technology will be the best.”

“Thus, we [at Airbus] are pioneering a variety of approaches,” he continues, “including the Clean Sky 2 multifunctional fuselage demonstrator (MFFD, see “STUNNING project …” and “Manufacturing the upper half of the MFFD”) and other European projects, including German-, French- and Spanish-funded national efforts where our partners are developing enabling technologies. And this project within TRumpf to demonstrate hydrostatic pressure consolidation is one of these technologies, where we can join parts very quickly without an autoclave or auxiliary materials required for vacuum bagging.” Although this technology is not yet mature enough to be included in the MFFD, he concedes, it has been demonstrated on a 1.2- x 0.7-meter part made using carbon fiber-reinforced polyaryletherketone (PAEK) unidirectional (UD) tape and, “with the current state of knowledge, could be applied for small parts on current aircraft as well as further developed for larger components.”

Developing the concept

Within the TRumpf program, Airbus defined the test parts to be manufactured while CTC was responsible for the composite manufacturing preparation, including production of skin layups and stiffeners, as well as project documentation. Siempelkamp was responsible for the concept and design of the tooling and also manufactured the test panels in its laboratory presses.

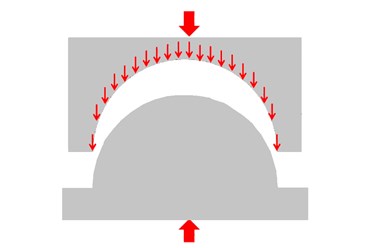

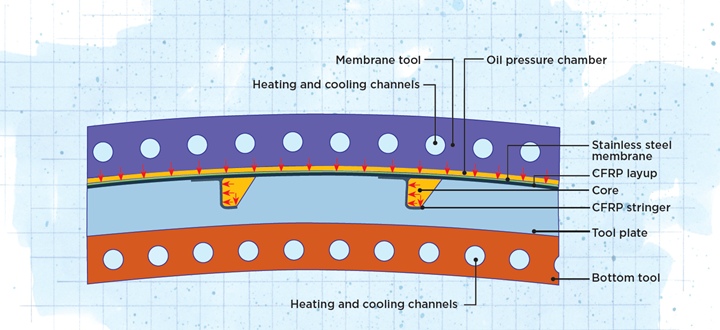

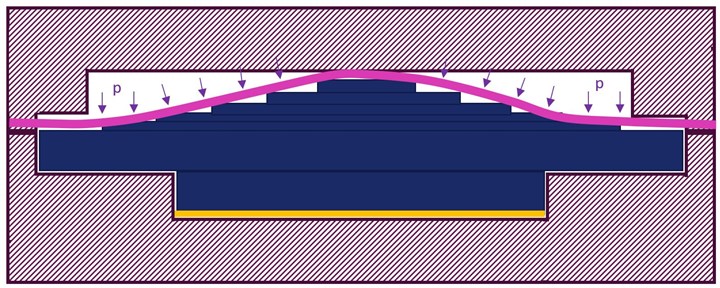

Fig. 1. Press tooling problem

One issue with using machined metal for both upper and lower molds is the lack of orthogonal force in a vertical-only press and inability to apply even pressure on curved surfaces due to the decrease in force over the radius.

Hydrostatic pressure, defined as pressure exerted by a fluid equally in all directions, inherently applies even pressure, explains Lennart Finger, project leader at CTC. “Such even distribution of pressure is crucial for proper consolidation of thermoplastic composite laminates and high quality in the internal structure of the finished part.” This has been a challenge using conventional hard steel molds, says Michael Schoeler, head of research and development at Siempelkamp. “Due to thickness tolerances of the material, too much pressure is exerted in some areas, and as a result, too little pressure is applied in others. Also, hard tool molds cannot produce an even pressure distribution for curved components, because the force decreases over the radius due to the increasing angle [Fig. 1]. By using a metal membrane with a heated fluid behind it, we can exert very even hydrostatic pressure across the part and mitigate the disadvantages and tolerance issues of using hard tooling for both upper and lower molds.”

CTC supervisor Remo Hinz gives more detail: “We needed a tooling concept that could address the problem where, in the past, prepreg layers were a few percent thicker and thinner in the preform. There are also dozens of layers, each with a positional tolerance of maybe 0.5 millimeter in one direction but 2 or 3 millimeters in another direction. And when you close a solid tool — without a membrane — then you have overpressure in some areas and underpressure in other areas.”

The process solution conceived by Airbus and Siempelkamp, Finger explains, “places pre-consolidated stringers into the lower mold and then the skin is laid on top, facing the membrane which acts as the upper tool. We then move through the consolidation process, heating both tools to the melt temperature of the thermoplastic matrix in the skin and stringers. We then use a press to keep the mold closed, while simultaneously building up the oil pressure behind the membrane with a pump or pressure accumulator so that the membrane presses on the surface of the preform. During this process, everything is completely remelted and then cooled to form a consolidated, fused and integrated structure.”

“The goal is also to have fast consolidation of thermoplastic layups into parts,” says Hinz, “and a technology that can be transferred to thermoset prepregs as well.” There is also a need for solutions to meet increased production rates, says Jörg Schwickert, composite manufacturing engineer at Airbus Operations in Stade, which produces all of the vertical tail planes for Airbus. Schwickert also works on the Fuselage of Tomorrow project. “We need to find a solution to produce a high rate of aircraft per month without doubling the number of autoclaves,” he explains. “I am part of the team looking at the industrialization of large CFRP [carbon fiber-reinforced polymer] parts including assembly processes like welding. We need the capability to manufacture more or less perfect parts and get rid of processes like shimming, which requires measuring every part prior to the next step so that it’s not possible to meet higher production rates.”

Temperature and tooling

Membranes have been used before. For example, CF/polyetheretherketone (PEKK) UD tape was formed into a demonstrator rib in the RApid high-Performance Manufacturing (RAPM) program led by Boeing (Chicago, Ill., U.S.). As explained in CW’s May 2020 article, “Manufacturing the complex geometry parts of RAPM”:

“The tooling approach developed used a thin aluminum bladder that was pressurized with inert gas at high temperatures, expanding to apply even pressure to all of the part’s surfaces during stamping. This made it possible to maintain hydrostatic pressure horizontally against the part’s vertical flanges while using a press that lacked horizontal hydraulic system and controls and thus acted only in the vertical direction.”

“The German project TP-Closed-Box used a silicone membrane for compaction of a thermoplastic composite preform,” says Paul Jörn, TRumpf project manager at Airbus, “but there were problems. To counteract the issues with a silicone membrane, Siempelkamp devised the metal membrane used in TRumpf.”

Hinz points out that this is a consolidation process, not a complex shape forming process — the stringers are already fabricated, and the skin is relatively flat. Still, tolerances are an issue, and the temperature is quite high. “For a thermoplastic composite consolidation process, the temperature is up to 400°C,” he notes. Siempelkamp chose to use a stainless steel membrane that is relatively thin, less than 1.0 millimeter thick, says Fabian Koeffers, technical lead for the TRumpf project at Siempelkamp. “This allows enough flexibility to apply pressure from the heated fluid across the membrane onto the surfaces of the part, including molding of surfaces with some curvature in the future,” he says.

“To meet the requirements for distributing heat along the tooling,” Koeffers adds, “we use oil, which we have used for decades to heat our presses. The upper and lower tools have channels for heating and cooling with oil, and we understand how to get good heat distribution, especially for cooldowns. Cooling demands a very good distribution because if you have large temperature differences over the surface of the part, this leads to poor quality. Also, the cooling process is the most critical point during consolidation and needs to follow a special profile to develop the necessary crystallinity for high mechanical properties in the thermoplastics used for aircraft fuselage structures.”

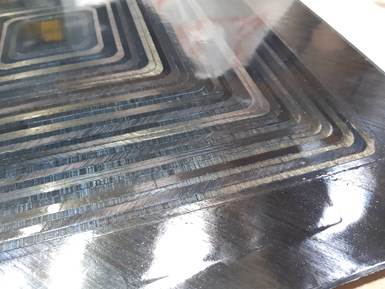

TRumpf test panels began as simple geometries to understand the membrane and material behavior. However, as the parts being manufactured became more complex, so did the press tooling. “The lower tooling enables the addition of stiffening elements via cavities,” explains Schoeler. “The prefabricated stringers are fit into these cavities, but we needed cores [inserts] to exert horizontal pressure on the stiffener webs and achieve consolidation through the complex geometry.” Koeffers explains that “the membrane acts like it’s elastic and can thus apply pressure through the skin layup onto the cores [see diagram with design results above]. Horizontal pressure is created by the angle of the cores to apply uniform compression in the stringer webs and maintain their geometry. The overall membrane concept is relatively simple, but it works well.”

The cores also enable easy demolding of the part, notes Finger. “We’re also using a liquid release agent in the molds to dispense with release foil, reducing waste.” The design and tolerances of the cores are crucial for a good quality part, notes Schoeler. “If the fit is too loose, then sufficient pressure is not applied to the stringers. If the fit is too tight, then we might squeeze material out of the stiffener cavity amongst other problems.” Siempelkamp trialed various core designs to find one that performed well throughout the process.

One issue Siempelkamp faced is that thermoplastics have a very low coefficient of thermal expansion (CTE), which is quite different from the large expansion of steels typically used for molds and cores. “It is important to match the CTE of the part and the mold to ensure good consolidation during the cooling process,” notes Schoeler. One solution is to use Invar or Kovar metal alloys, which have minimal expansion with heating, but these are also very expensive, with long lead times. Siempelkamp thus turned to its foundry division, Siempelkamp Giesserei, which has decades of experience in large metal castings and alloys. It examined a variety of alloy concepts and molecular lattice structures before achieving a material that fits optimally with the thermal expansion behavior of thermoplastic composites and the TRumpf consolidation process. “The new casting alloy was used to produce a 500- x 500-millimeter test mold including cores,” says Schoeler. “Both the machining of the cast mold and the consolidation tests with the mold and cores showed optimal results.” He notes this alloy provides a competitive advantage over classic machined Invar molds, due to its manufacturing advantages and superior behavior demonstrated during composites consolidation.

Challenge part demonstrators

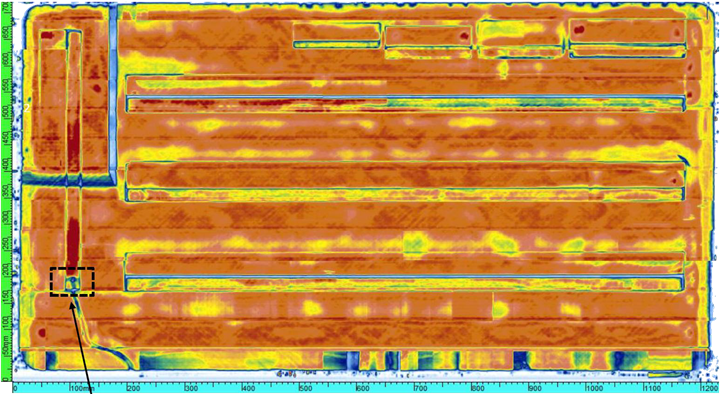

Fig. 2. High-quality consolidation

Prefabricated stringers and clips are shown sitting on the machined lower tool, where they are inserted before placing the skin layup on top and then pressing to consolidate. Ultrasonic C-scans of the resulting challenge panel (top image) showed no defects other than a thermocouple placed in the part (dashed box at lower right of scan).

As the test parts increased in complexity, several challenge panels were designed to demonstrate the ability of this process to co-consolidate a stringer-stiffened fuselage panel made using CF/PAEK UD tape in one shot.

“The penultimate challenge panel has a skin which is about 1.2 x 0.7 meters,” says Finger, “with three straight stringers, one joggled stringer and four clips to demonstrate different core inserts and our ability to consolidate such features.” A joggled stringer has local changes in shape to conform to its mating surface throughout ply buildups and drop-offs in the skin. “We manufactured the challenge panel in about 70 minutes,” says Koeffers. This cycle comprised a 30-minute ramp up, 10-minute hold and 30-minute cooldown. “This was a demonstration trial,” he notes, “but with sufficient heating and cooling capacity, the cycle could be reduced to one hour.”

“We checked the consolidation of the challenge part using ultrasonic C-scan inspection and found no defects,” says Finger. The color gradient seen in Fig. 2, he says, “is a common pattern according to our inspection technicians, a result of the ultrasonic probe frequency and coupling with the part. The black dotted box shows the main defect detected, which was a thermocouple used to monitor temperature in the part. No other defects were found.” A final challenge part, measuring 1.35 x 2.0 meters and curved with a radius of 2.0 meters is in the process of being manufactured and tested.

What about process control? “We have a control system in the press,” explains Schoeler, “and for the pressure from the oil cavity behind the membrane, we are using another control system which we can add to our press controls. For temperature, we place thermocouples into holes at different depths in the lower tooling plate, which gives us the temperature distribution. We also place some thermocouples in the part, and we have a good knowledge of the tooling itself, so we can maintain the specified pressure and temperature profile throughout the process and know this is sufficient for good part quality.”

Demonstrated benefits, future applications

The team is pleased with its success so far and sees many benefits. “We are combining the speed of the press with the homogeneous pressure applied by the autoclave, but without the vacuum bag and ancillary materials,” says Koeffers. Also, because stringers are integrated while consolidating the skin, says Vichniakov, “you don't have additional manufacturing processes, so this further reduces time and cost. It also opens new possibilities with the stringers, for example, because you don't need to weld them, and you are only welding the fuselage frames.”

Regarding the integration of frames, the team has investigated consolidating stringers in two directions. “We produced one such test panel and the stringers were already connected together,” says Vichniakov. “This is another real benefit that I think we can achieve with this technology and the enabler is thermoplastic consolidation, not welding.” But wouldn’t that require very complex tooling? “Yes,” he concedes, “this is part of our investigation. We are looking at what level of integration makes sense, stiffeners in one direction or two directions, and various applications of this technology. But this also will depend on the production rates. We could just use this process to produce the skins very quickly and then weld the stringers and frames. But the panels we’ve produced in this project show excellent consolidation of the stiffeners — which we are the first in the world to achieve in this way — and we believe this approach has potential for significant cost savings.”

Vichniakov notes that the autoclave process used today for composite aircraft parts “is very time consuming and uses a lot of ancillary materials. And in the case of fuselage panels and other curved parts, if you try to consolidate these with simple vertical pressure, then you don't have the necessary horizontal pressure.” He adds that instead of 6 to 15 bar of pressure typical for an autoclave, “we are applying a 20- to 30-bar hydrostatic pressure across the complete surface. There is no other technology that can do that now.”

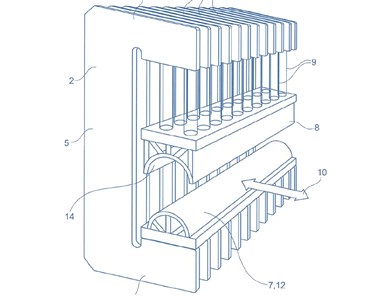

Fig. 3. One membrane, multiple ramped layups

The flexibility of the metal membrane (top) enables ramped laminates on the upper/outer side of the consolidated part (bottom). The membrane will adapt to the overall geometry of the part, while remaining in its elastic material state, without permanent deformation. This enables one tool to be used for different layups, and in general, parts with different thicknesses.

Schwickert comes back to rate and the speed this approach offers not just during and after the process, but before. “For the test parts we have produced, the skin plies were very loosely stacked together, so an AFP [automated fiber placement] layup only needs to be easy to handle and could be produced very quickly. We should also aim to get rid of all the release foils, because these materials for high-temperature thermoplastics — such as Kapton — are very expensive. This is an additional burden that this membrane-based production would alleviate.”

Another cost savings, says Jörn, “is that the membrane lets us get rid of one of the two rigid tools, so slight changes in geometry can be implemented with low cost.” Koeffers adds, “For example, we have shown that the membrane can compress a ramped layer preform. This makes it possible to use one tool to produce different layups in the part and, in general, components of different thicknesses [Fig. 3].”

The focus now, says Hinz, is to mature and scale this technology, as well as show its potential for all components, not just fuselage skins. “Any flat or curved skins with thickness variation could be made in this way, with or without integrated stringers and stiffeners,” he says. “That could include flap designs or doors, for example, and also for thermoset composites not just thermoplastics.” Because of the short cycle time, there is potential to translate this technology to urban or advanced air mobility [UAM/AAM], for example.”

Well before UAM/AAM begins to demand thousands of aircraft per year, Airbus will have significantly increased its production rate for narrowbody jetliners. In May 2021, it announced a rate of 70 aircraft/month by Q1 2024 for the A320 family that will possibly reach rate 75 by 2025. “It’s not a secret,” says Vichniakov, “and for even higher rates, our lead time for producing parts will be significantly less. This is exactly why we need this technology, which is able to reduce the lead time for shell production.” And, adds Schwickert, “without all of the current process materials and waste in thermoset composites production. When you think about higher production rates for big parts, there are massive technological advantages and differences which make this technology, for us, one of the fundamental bricks for future aircraft manufacturing.”

The project LuFo TRumpf was supported by the Federal Republic of Germany, Federal Ministry of Economic Affairs and Climate action on the basis of a decision by the German Bundestag.

Related Content

STUNNING project completes lower half of MFFD

Clean Sky project has delivered the 8 × 4 meter welded aerostructure component, aided by advanced thermoplastic composite technologies and smart robotics.

Read MoreHexcel, Arkema present CFRTP aerospace demonstrator in HAICoPAS

Project optimized design and production of UD composite tapes reinforced with a PEKK matrix, using a continuous in-situ welding (ISW) assembly system.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)