iComposite 4.0 — cutting composites cost by 50%

An intelligent, integrated process using 3D fiber spraying, inline inspections/simulation and embedded RFID chips to cut scrap and rejections for structural HP-RTM epoxy parts.

Share

The mission of the Aachen Center for Integrative Leightweight Production AZL (Aachen, Germany) is to develop breakthrough technologies for the mass production of lightweight composite parts. It began the iComposite 4.0 project in 2016, and by its completion in Dec 2018, AZL and its partners will have demonstrated an integrative and self-regulating process for large-scale production of hybrid (glass and carbon fiber) composite parts. The goal is to cut cost 50% versus current processes for structural automotive parts, but the intelligent process chain developed will also have application in other industries.

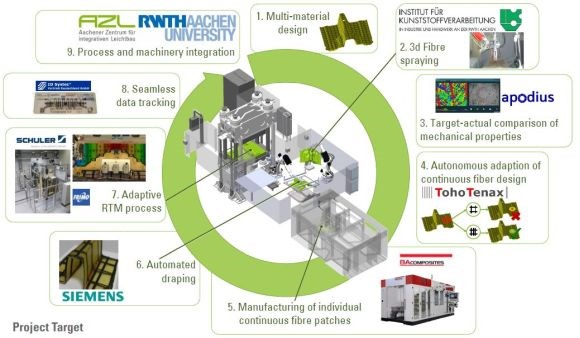

iComposite 4.0 aims to develop an integrative and self-regulating process chain to produce adaptive, automated preforms, resin-infused and consolidated via an intelligent HP-RTM process into lower-cost, high-volume structures for applications in automotive and beyond. SOURCE: AZL.

CW interviewed Sebastian Stender, a research engineer at AZL, and Patric Winterhalter, composites product manager at German press manufacturer Schuler (Göppingen, Germany). “AZL contacted Schuler with the idea of this project,” says Winterhalter. “We worked together to obtain funding from the German government (BMBF).” They also assembled a network of strategic partners:

| AZL | Process automation Process and machine integration |

| Schuler | Adaptive press control Project coordination. |

| Frimo | HP-RTM mold (2 tools) Three-component HP-RTM injection unit Adaptive RTM control |

| Siemens | Preform draping simulation to derive producible patch designs Intelligent production control system |

| BA Composites | STAXX 1700 for carbon fiber patch production |

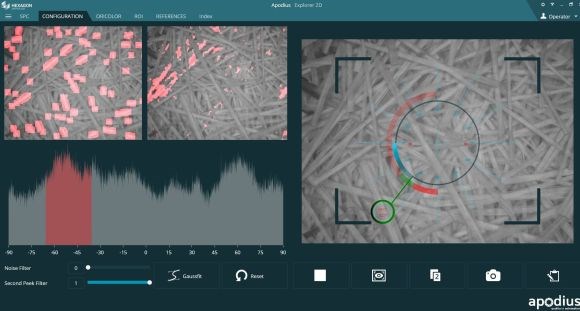

| Apodius | Optical quality control system for determining preform properties and evaluating draping quality |

| Toho Tenax | Process and part performance simulation |

| ID Systec | RFID chips and data acquisition |

| IKV | Fiber spraying process Material testing and analysis |

| PTKA | Project management for BMBF |

In addition to these project members, iComposite 4.0 is also supported by several other companies, such as Busch Vacuum Pumps and Systems, Dow Automotive Systems, Kuka Roboter GmbH, LAP GmbH Laser, J. Schmalz GmbH and Karlheinzbauer representing EMS Grilon.

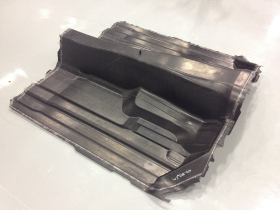

“In our first two years, we looked at the overall process design and worked to develop each component process,” says Stender, “including preforming and high-pressure resin transfer molding (HP-RTM). Now, in our third year, we are combining all of the technologies and researching dependencies and effects, in pursuit of zero defect manufacturing.” The first trial case is an automotive floor pan which integrates three previous parts (including tunnel) into one large integrated module. This floor pan is roughly 1.5m x 1.5m with a depth of 45 cm.

Fiber deposition preforming

iComposite 4.0 begins with an HP-RTM process chain, but instead of conventional noncrimp fabric (NCF) preforms, it uses fiber spraying as the preforming process. “We save money and reduce scrap by using rovings instead of fabric,” says Stender. He notes that using fabric in the composite preform can generate as much as 60% scrap. “Faurecia and Toho Tenax [Teijin Carbon Europe as of Apr 2018] have been using fiber spraying as a preform method for several years. There are two versions: wet fibers and dry fibers. We use the latter.”

Wet fiber preforms have historically been used in boatbuilding and in the production of glass fiber reinforced plastic (FRP) tubs, showers and spas, referred to as “sprayup” using a “chopper gun”. Being an open molding process, this sprayup method has historically presented issues with volatile organic compound (VOC) emissions from the polyester resin typically used. However, this is not an issue in iComposite 4.0 because the glass fiber is dry and later injected with resin in a closed-mold HP-RTM step.

Glass fiber rovings (currently 2400 tex) are fed into a chopping robot which then sprays long fibers — desired lengths range from 25mm to 50 mm — onto a mold equipped with vacuum/suction to draw the fiber down onto the preform mold. The mold sits on a rotary table. Combined with the multi-axis movement of the robot, complex-shaped preforms are possible. “We are able to orient the fibers as desired by regulating the spray outlet,” explains Stender. “Doing so, we gain some anisotropy in stiffness — such as a ratio of 3:1 in the spray outlet direction.”

“IKV has performed research on the oriented fiber spraying process and determined the requirements for this demonstration part, which features corners and steep flanks,” Stender explains. “For the preform design, they have found how to adjust the process to the part, for example, changing the fiber length per local deviations to best obtain the shape.” Thermoplastic binder is used, which will be heated to fix the preform.

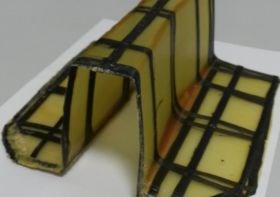

These early trials show how UD carbon fiber patches produced by a Broetje STAXX 1700 machine are added to the sprayed glass fiber preform to add local reinforcement where needed. SOURCE: AZL and Siemens.

Adaptive preforming

Though the local fiber areal weight of the preform varies by about 10%, Stender notes this fluctuation is not an issue because the preform will be adaptively strengthened in the next step of the process.

A Broetje STAXX 1700 machine (see “Preforming goes industrial: Part 1”) is used to produce tailored patches from continuous, unidirectional carbon fiber (CF). “Siemens provides the preform simulation,” he explains, “taking the 3D part shape and transforming that into 2D unidirectional patch designs producible by the STAXX machine.” These patches are then placed to locally reinforce the sprayed glass fiber preform where needed. “The patches are adapted based on simulation using data from the fiber spraying,” says Stender. “This will balance out the fluctuation in the base preform areal weight.”

The fiber spraying data Stender refers to is generated by scanning the glass fiber preform with an Apodius (Aachen, Germany) Vision System (AVS). Using a camera and laser sensor, the AVS provides a 3D fiber orientation and fiber area weight measurement of the preform. These are fed into a part performance simulation and later into an HP-RTM process simulation— both completed by Toho Tenax (now Teijin Carbon Europe, Wuppertal, Germany).

The preform is scanned after fiber spraying and again after UD patch placement. “A single robot is currently being used for both spray deposition and preform inspections,” says Stender. “This is our bottleneck right now, but in production, these functions can be split across separate robots.”

iComposite 4.0 uses the Apodius Vision System (AVS) to scan the preform

after fiber spraying and again after UD carbon fiber patch placement to:

- Characterize product fluctuations

- Adapt subsequent processes to balance out fluctuations

- Control not just process parameters but part properties.

SOURCE: Apodius.

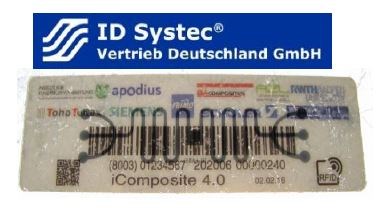

In addition to adaptively modified UD carbon fiber patches, every preform will also get its own RFID chip. “Every UD patch may get one as well,” says Stender. “We are still deciding this. With these embedded chips, we will know which preform is in which floor pan part and also which process settings were used.”

ID Systec (Neumünster, Germany) is the supplier, developing RFID chips that can work with CF and composites. “They already provide one for injection molded plastics,” he notes. “However, because the CF has electrical conductivity, you must block the chip. We almost must show there is no impact to the part forming or mechanical properties by embedding the chips.”

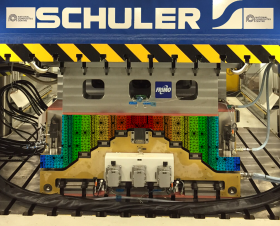

The HP-RTM press supplied by Schuler can adapt the force distribution across the demonstration automotive floor pan part (left) to adapt for shape and fiber volume (right). SOURCE: FRIMO, Schuler, AZL.

Intelligent HP-RTM

The finished preform is then placed into an HP-RTM mold and press. Schuler and FRIMO founded a collaborative initiative called the Composites Alliance several years ago. Schuler develops press technologies and FRIMO supplies the HP-RTM molds, mix/meter/dispense (MMD) units and other equipment. It is this collaboration which has supplied the intelligent HP-RTM equipment for the iComposite 4.0 process line.

Schuler installed a new 18,000-kN press at AZL in 2016. “This is a very big and multifunctional press,” says Winterhalter, “able to build structural parts like this seat pan. It has also been developed to help reduce scrap via intelligent functions. For example, we can adapt the force distribution across the press and the part. In other words, you can open the mold a bit more in the areas where there is more fiber. We can also control and adapt the resin injection as well as the closing profile of the press to optimize the process parameters for a reduced cycle time.

Winterhalter notes this is a short-stroke press, “the same type as the one installed at the IACMI facility in Detroit, but a bit smaller.” This type of press reduces the amount of vertical space required, achieving the work stroke from the bottom via several pistons. “We can control these individually and by this design the operating costs can be reduced dramatically due to a significant reduction in the energy consumption,” he adds.

The beginning installations for the iComposite 4.0 process chain at AZL, with the 18,000-kN Schuler short-stroke press in the background. SOURCE: AZL.

The resin injected is Dow VORAFORCE 5300 fast-cure epoxy. All parts of the process are geared toward a 5-minute HP-RTM cycle time.

Reducing cost and scrap

“We are comparing this demonstration part to the previous version made with 3 continuous fiber, NCF preforms and HP-RTM,” Stender explains. “We started with calculating typical costs for an RTM process chain — 15% investment, 35% operation, 50% material. We then began working to detail where and how iComposite 4.0 reduces this.” Cost savings were estimated for multiple areas:

- 30% cost savings via increased production.

- 30-40% reduced labor via automation of preforming.

- 30-40% material reduction via fiber vs. fabric – using the right material at the right location and also scrap reduction of 25-50%.

- 5-20% improvement in production rejects via zero defect manufacturing.

“All of this combined gives 49-64% overall improvement,” says Stender. “We established a goal of 40% improvement with BMBF and exceeded that, reducing cost by 50%.”

For more information, visit AZL at JEC World 2018 (Mar 6-8, Paris, France) in Hall 5A, Booth C55 and Schuler press in Hall 6, Booth C56.

Related Content

CompoTech uses integrated loop technology to create high-performance mountain bike

CompoTech features its CDuro Epona mountain bike fitted with custom suspension forks, manufactured using its AFL winding and integrated loop technologies.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreJCB Aero aircraft interior flooring panels incorporate SHD composites

High-performance carbon fiber prepreg using SHD’s FRVC411 epoxy resin system resulted in a durable, compliant design for the MRO market.

Read MoreTCR Composites introduces TR1116 snap-cure epoxy prepreg resin system

Designed for press-cure applications, the resin system is highlighted for its snap-cure capability and tailored properties.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More