In-situ composites sensors for increased production rates, smart processes and life cycle monitoring

Com&Sens FBG sensors are embedded into pressure vessels, rudders and bridges, with new edge and surface connection technology, aimed at cost-effective serial production and monitoring of composite structures.

Share

Com&Sens (Eke, Belgium) claims it has a non-intrusive, in-situ sensor for measuring changes in temperature, strain or pressure within a composite, but which also provides resin flow and cure monitoring during processing and strain mapping throughout a structure’s manufacture, assembly and service life. Applications? Think beyond structural health monitoring (SHM) of bridges, wind turbines and ship rudders — all of which they currently do — to assessing strain levels within the plies of composite pressure vessels during filament winding and cure, and then using those same sensors to monitor the tank’s integrity during thousands of refueling cycles to predict needed maintenance and enable recertification.

“What we are offering is a digital solution that provides a digital twin data-pool for every composite pressure vessel produced,” says Grégoire Beauduin, business development director for Com&Sens. “With one set of sensors, data is gained from parameters during composites processing, through quality testing, certification and service life to recertification.” This same digital solution is being developed for many other composites applications, from satellite parts to bridge decks.

The power of light

These optical fibers are like tiny glass strands with small dimensions (100-200 micrometers in diameter) and can guide an enormous amount of data compared to electrical wires. Fiber optics have replaced copper cables for transmitting information and are used, for example, to provide broadband internet and medical imaging. Because fiber optics can transmit data from multiple sensors in a single strand — i.e., multiplexing capacity — they are replacing electrical resistive strain gauges (RSG).

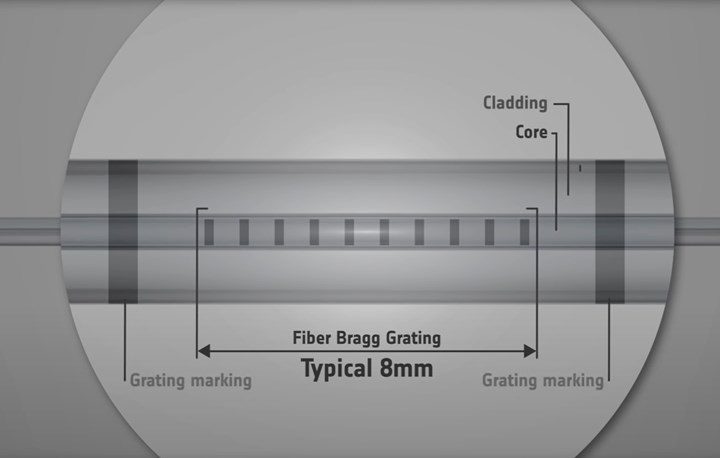

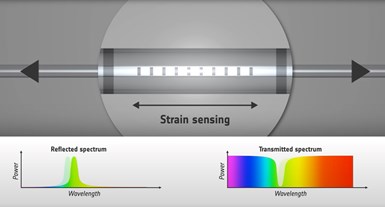

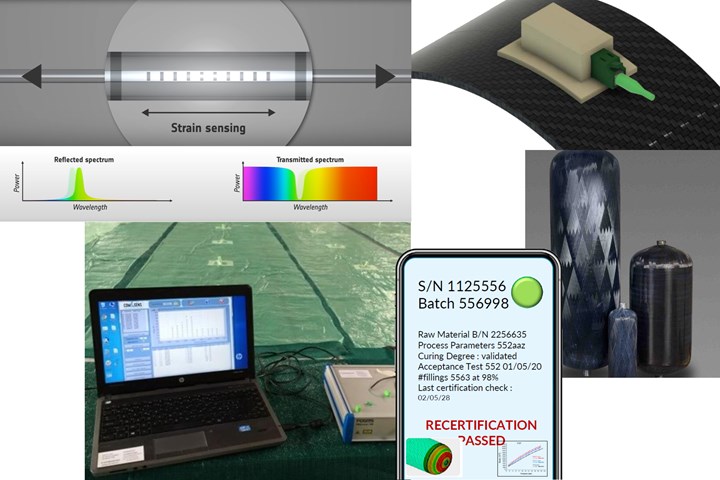

To be used as sensors, fiber optics use Fiber Bragg Gratings (FBG), which is a small section of the fiber that is inscribed with a pattern that reflects light and acts as a sensor. The distance between the reflection points that comprise this pattern are always equal. Only the wavelength of light that matches this distance between two reflection points is reflected; all other wavelengths pass through unaffected. When an FBG is subjected to strain, the distance between the reflection points — as well as its refractive index — changes, and thus, a different wavelength is reflected. FBG are sensitive to temperature, as well as strain, and in cases where both are changing, measurement of each can be isolated by using well-known compensation methods.

Fiber optic sensors (FOS) using FBGs have been studied for decades, including successful demonstrations with a wide range of composites structures and processing methods, as well as for long-term structural health monitoring (SHM), both for “smart structures” but also within adhesive bondlines. FOS are also being used to validate designs and finite element analysis (FEA) and as a tool for digital testing and certification (see “Fiber-optic sensors shed light on the toughest composite design challenges”).

Making FOS practical

If this technology works so well for composites and is already so well-proven, why is it not more widely used? “It is being used in composites, but mainly in a test environment and at lab scale,” says Com&Sens co-founder Eli Voet. “There is a perception that fiber optic sensors have great advantages but are really fragile and expensive. Our goal is to make this technology easy and cost-effective for even small companies to use on an industrial scale, both to monitor process parameters as well as the finished structures during service.”

Com&Sens was founded in 2012 as a spin-off from Ghent University (Ghent, Belgium) by Voet and co-founder Geert Luyckx. Both completed PhD research in the use of FOS and FBG to monitor complex, aerospace composites, made using both thermoset and thermoplastic matrices. Com&Sens — which stands for composites and sensing — followed via their collaboration on technology to embed these sensors in a cost-effective, practical way.

“We make the fiber optic more robust by embedding it inside a single flat or round composite strip,” notes Voet. “This enables versatile and cost-effective installation within and on the surface of almost any construction material that also can withstand harsh environments. We use an in-house pultrusion line and can produce strips from one to hundreds of meters in length. These typically include from 20 up to 40 sensing points. We have experience embedding sensors in almost any composites production process, including filament winding, pultrusion, braiding, prepreg layup, AFP and ATL [automated fiber placement and tape laying], and every version of RTM [resin transfer molding] and infusion.”

But can FOS be embedded within the composite part and not degrade mechanical properties? “There is a huge number of papers documenting this,” says Voet. “We are talking about optical fibers that range from 100 to 200 micrometers in diameter, including the fiber coating. A human hair is on the order of 75 micrometers. The FRP yarns are in the same order of magnitude as the optical fiber, depending on the materials being used. On a micro level, yes there is an influence, but on the structure, there is negligible influence. For example, the effects of process variability and woven fabric patterns in a laminate are typically much higher. We also try to place the fiber optic line along the reinforcement orientation or between two UD fibers so that it really doesn't affect mechanical properties.”

Improved connection technology

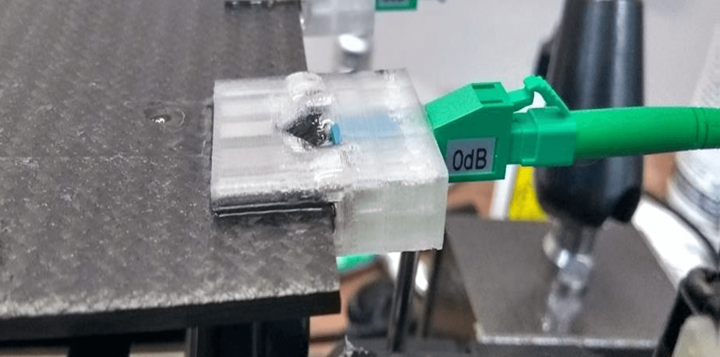

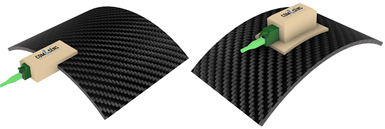

Com&Sens has made sensor interrogation easy via its patented edge and surface connection technologies (bottom). A prototype is shown at top. Photo Credit: Com&Sens

Another issue is interrogation. In order to access the information provided by the FBG sensors, a physical connection must be made between the FOS and a data acquisition unit. This is another area where Com&Sens has developed key technology. “The challenge to embed the required connector to interrogate the sensor was always a struggle in the composites production process,” says Beauduin. “We developed a unique edge connection technology that allows us to reconnect to the embedded fiber optic that has been cured and machined as part of the composite part. The fiber optic is just another element in the stacking sequence — you don't modify the mold or cure cycle. After the part has been machined, we are able to align and connect the embedded optical fiber using a non-intrusive connection method on the edge of the part to any standard fiber optic pigtail.”

This patented technology (US 10466419) is being further developed for a surface connector. “This will allow interrogation of the embedded fiber optic sensors from the surface of the part,” says Voet. “We see this technology as a game changer,” adds Beauduin, “that will really open the door for automated and series production of smart composites.”

“As a forerunner in fiber optic technology,” says Voet, “Com&Sens is closely following and evaluating the newest developments on the market and working with state-of-the-art interrogators which fit our requirements. These FBG interrogators are becoming smaller in size, and when plugged into a smart composite panel with an embedded sensor network, they provide constant monitoring up to 5 kHz or even more depending on the manufacturer.”

“No re-calibration is needed once installed,” Voet continues, “because we use absolute value measurement. The interrogators — via the patented Com&Sens connection — then transmit the FOS data to a PC for immediate monitoring, data visualization, archiving and further post-processing analysis.”

Making FOS cost-effective

Voet and Beauduin cite a list of advantages that make FOS and FBGs more cost-effective than other sensors because they don’t require special protection for lightning strike, static discharge, electromagnetic radiation (e.g., induction heating and welding), chemicals, sea water, oil, vibration, pressure or temperature, with a maximum for the latter of 10 bar and 300°C long term. Another key point is that each FOS line can include up to 40 sensors with a minimum spacing of 1 centimeter in between. The exact number depends on the application, including the optical bandwidth of the interrogator and expected strain ranges.

The average cost of an FBG sensing point is €50-125, says Beauduin, “for non-automotive composite pressure vessels, where the volumes are lower, or where we deal with one-of-a-kind products and designs (e.g., space). This goes down with volume. In our work with composite pressure vessels, we typically need a low number of sensors, so that very few fiber optic lines are required, or even just one.” He adds, that if applied to 100,000 vessels, the cost would come down to roughly €25–35 per sensor. “Taking into account the added value over its complete lifetime,” says Beauduin, “this is a negligible cost.”

This life cycle monitoring for multiple design, production and in-service benefits is another cost advantage, he says. “We can offer different benefits with just one set of sensors: We optimize and digitize the process and make every composite structure that leaves the factory ‘smart’ and ready for monitoring during its service life. We are enabling a complete flow of digital data from understanding and proving the part design, to optimizing the production process and then to a digital ID card that supports its digital twin.”

This could facilitate recertification of composite pressure vessels at the currently required 10-year inspection intervals. But, actually, it would enable the same for all composite structures at the end of their service and/or design-specified lifetime. “That digital twin that our sensors enable takes all the life cycle information, from design to production to data during service and feeds it also into a larger repository,” adds Voet. “For example, this could be from every composite vessel that a producer makes. By then applying AI [artificial intelligence], and/or machine learning data analysis approaches, even more understanding and optimization can be gained.”

Resin flow and cure monitoring

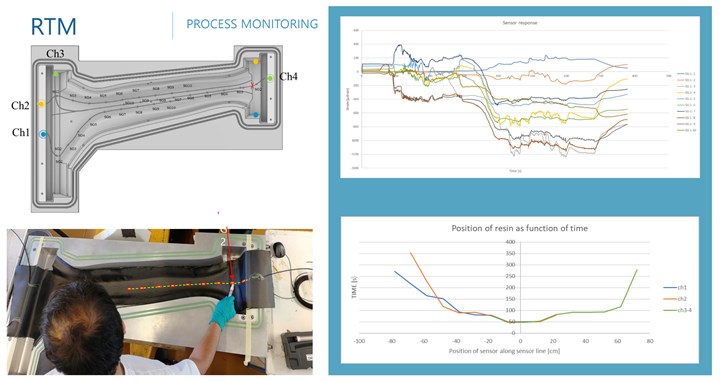

The image below is from an RTM application where Com&Sens provided resin flow monitoring. “We used a network of four channels, with up to 10 sensor points per channel,” explains Voet. “We showed both the strain and resin position as a function of time. And we can see this also for resin infusion of very large structures, including tracking at resin inlets and exits throughout the cure cycle.”

Process monitoring of an automotive structure showing strain (top right) and resin position (bottom right) as a function of time during RTM. Photo Credit: Com&Sens.

“We have done this also on very large composite pressure vessels,” says Beauduin. “And those results are confidential, but we get really in-depth information on what is happening. So, we are not using a strain gauge measuring the surface, but instead we are working to understand the effects within the layers of the composite laminate.” Voet notes the FOS lines are placed inside the ply stack, “depending on the critical zones of the part. Customers obviously know what they want to measure and where they want to manage temperature, pressure, strain or waste.”

Pressure vessel process control, tank monitoring and recertification

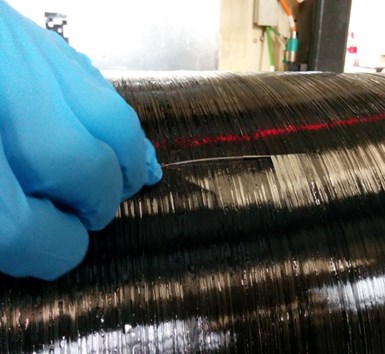

Manual placement of a fiber optic sensor in a filament-wound pressure vessel. Photo Credit: Com&Sens

For pressure vessels, Com&Sens is manually embedding the fibers during the filament winding process, says Beauduin, “but we are also working on automatic placement. As soon as they are placed, however, we can begin online measurement during the process and clearly see, for example, the change in different parameters between hoop and helical layers.”

“Even in small production batches of standard vessels,” he continues, “we have seen huge differences in fiber tension of the different layers, which has a large impact on product quality. So, we can already monitor during the process and use the embedded sensors for design validation, as well as to monitor and gain a better understanding of the cure cycle and the strain effects during cure. Producers then can use this to achieve better properties and efficiencies during the winding and cure cycles.”

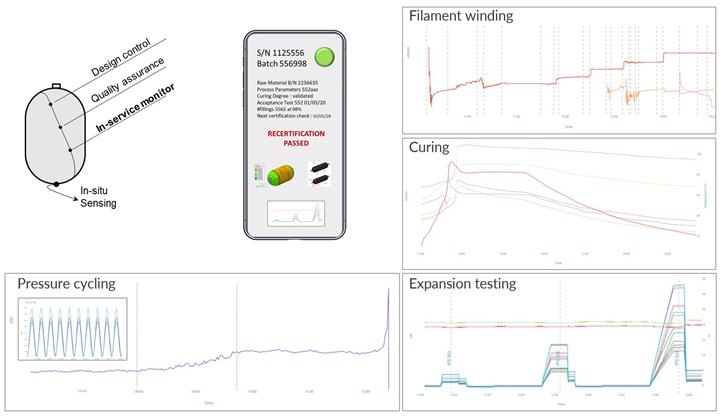

“That same set of sensors can then look at the pressure vessel during fillings to see any degradation in tank integrity and if there is a need for maintenance,” says Voet. “Our goal is to extend the lifetime of these pressure vessels. The graph at top right in the image below shows the strain evolution, between 10 cycles, 2,000 cycles and 5,000 cycles. And how the tank performs can then be fed back into design.”

Com&Sens fiber optic sensors are used to monitor parameters such as strain during composite pressure vessel winding and cure (graphs at right) and between the different layers during refueling/filling and expansion testing (bottom right) as well as for thousands of refilling cycles (bottom, left). The same sensors can help to create each pressure vessel’s unique thumbprint/digital twin comprising its material, process, testing and in-service data. Photo Credit: Com&Sens

One of the key issues in composite pressure vessel design is the need to increase storage efficiency and reduce cost. As a manufacturer of hydrogen storage tanks for its Mirai fuel cell car, Toyota improved the storage efficiency in its tanks by reducing the carbon fiber-reinforced polymer (CFRP) laminate by roughly 20%. “Pressure vessel manufacturers will have to prove their designs in order to decrease material usage and reduce costs,” says Beauduin. “And they will also require monitoring as they ramp up production and try to meet the required volumes in the coming 5 to 10 years.”

“We also see that these companies will need to be much quicker to market when developing new vessel designs,” says Voet. “Today, the time from start of a new design to hitting the market is much too long for the demand that must be met. We also see that for pressure vessel and vehicle operators, there is no traceability in these tanks today. A tool is needed to help predict failure, trace the root cause when failures occur and enable predictive maintenance. There is little to no information available today on vessel integrity or vessel usage. And those vessels should also pass recertification. If not, that increases cost. The recertification processes today could be made much more cost-effective.”

Other case histories

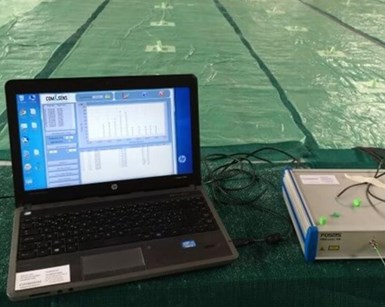

Com&Sens is already very active in deploying FOS in pipelines, monopile foundations of wind turbines, underwater turbines and rudders and in civil engineering applications including bridges and roads. The company has worked on several projects with FiberCore Europe and InfraCore (Rotterdam, Netherlands), including:

- 2015 installation of several FOS lines to measure creep and in-service forces on one of the 12.9-meter-high, 6.2-meter-wide, composite lock gates in the Wilhelmina Canal (Tilburg, Netherlands);

- 2016 construction of bio-composite pedestrian bridge at the Technical University Eindhoven campus (Eindhoven, Netherlands) where FBGs were embedded to monitor resin infusion of the bridge deck, to validate FE modeling parameters of the design and to enable long-term remote monitoring of the bridge (SHM);

- 2019 installation of more than 200 FBGs for long-term SHM of the 66-meter-long, 4-meter-wide Ritsumasyl bio-composite bicycle/car bridge in the Dutch province of Friesland;

Com&Sens installed fiber optic sensors in one of the composite lock gates for the Wilhemina Canal, to measure creep and in-service forces. Photo Credits: Com&Sens, FiberCore Europe

The latest project was completed earlier this year. “We performed a full-scale test to evaluate a new infusion monitoring technology with great results,” says Beauduin. “We explored the issue of demolding and were able to measure the residual stresses inside the composite laminate. We can also monitor key parameters during infusion and curing and then give the green light when each is complete and when it’s okay to demold without incurring too much residual stress in the laminate. The goal is to make these processes as efficient as possible, for different resin and fiber combinations, based on what is really going on the laminate.”

Com&Sens embedded FBG sensors into this CFRP yacht rudder to validate FEA, monitor loads in service and provide force feedback to the helm operator for more efficient steering. Photo Credits: Com&Sens, Royal Huisman

Two years ago, Com&Sens began work on another large structure — a composite rudder for an 80-meter-long Royal Huisman (Vollenhove, Netherlands) yacht. Composite materials and engineering supplier Gurit (Wattwil, Switzerland) asked to integrate sensors, says Voet, “because they had never designed such a large CFRP rudder and wanted to understand the loads during service. We embedded the sensors during the rudder fabrication and did some load testing of the structure in the factory. We also made several sea trials where we could see the strain levels in the rudder during sailing.”

He adds that Royal Huisman is now working with the rudder fabricator Rondal (Vollenhove) to use the sensors to develop a force feedback system. With smaller rudders, there is a sense of feeling, of push back in the rudder, that the boat operator uses to gauge how much force to apply in steering. “But this is such a large yacht and rudder,” Beauduin explains, “you lose this sense of feeling and it’s more challenging to steer.” This force feedback system will amplify measurements from the Com&Sens FBG sensors to enable the operator to feel the load in the rudder and react in real-time to steer the boat more efficiently.

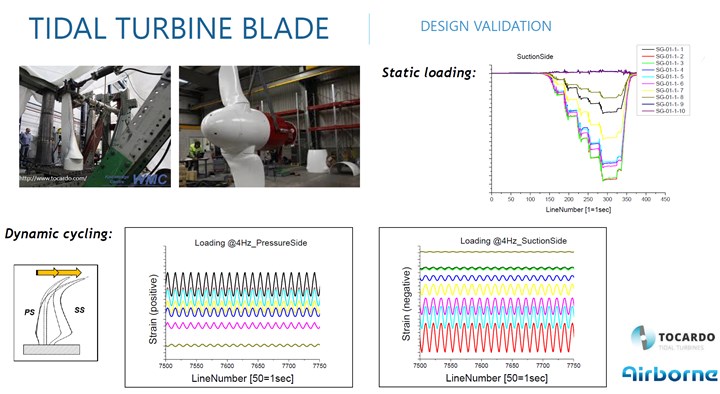

The company has also embedded FBG sensors in glass fiber-reinforced polymer (GFRP) tidal turbine blades, working with Dutch partners Airborne (The Hague) and Tocardo (Wieringerwerf). The sensors were used for design and FEA validation as well as testing at a certified test center as well as structural monitoring once the turbine was installed in the ocean.

“We are also doing an R&D project with Damen Shipyard (Gorinche, Netherlands) to test an adhesively bonded hybrid joint between a GFRP superstructure and steel substructure,” notes Beauduin. “We are monitoring the adhesive bondlines between these two materials with the goal to develop a certification protocol in collaboration with the marine classification society Bureau Veritas.” He notes Com&Sens is also performing metal weld monitoring for more than 30 offshore wind turbines. “We install four fiber optic lines in the monopile foundations and monitor the welds for initiation of cracks.”

Voet notes that Com&Sens could also provide monitoring for thermoplastic composite welds. Speaking at CW’s June 2021 webinar on induction welding, Voet pointed out that because FBG sensors are unaffected by electromagnetic force, a single fiber optic line could be placed in the weld substrate and not only provide real-time measurement of temperature and pressure during parametric studies and the actual welded assembly process, but also monitoring throughout certification testing and service. All of these issues are key if induction welding is indeed to be used more widely in aircraft structures.

Another high-growth area for FBG application is space launch structures. Com&Sens is working with Dawn Aerospace (Christchurch, New Zealand and Delft, Netherlands) to enable production of turnkey small satellite propulsion systems, including pressure vessels for space. “These typically have long development cycles,” says Voet. “Our goal is a design tool based on our FBG sensor data to help speed time to market for serial production of specialized pressure vessels for space vehicles. We have already obtained EASA approval for use in space pressure vessels and estimate we can help cut development time by 50% and reduce mass, cost and process variability by 10%.”

Enabling increased production rates

New Space is not the only industry looking to ramp production rates while reducing costs and increasing sustainability. These are, in fact, the major drivers Airbus has stated for future commercial aircraft production. “We’ve been talking with Airbus, Safran and many key aerospace players,” says Beauduin, “but so far, progress has been slow. So, for now, we are focusing more on pressure versus because those manufacturers see the value of cutting time to market and improving their ability to increase production rates while improving quality.”

He continues, “To achieve, in a cost-effective way, the current dramatic increase in pressure vessel production that is being demanded, manufacturers will need to have much better control of the production process. With our technology, they can control process parameters and then we can link this with the product quality and also enable monitoring of the pressure vessel during its service life — all with one single sensor line.”

Voet and Beauduin see a huge potential to make a difference in composite pressure vessels. “They see the benefits that we can bring to the market,” says Beaudin, “and we have had a great response from the producers so far.” Voet notes that Com&Sens is a small team, currently totaling nine members, “but we are unique in this field due to our composites expertise, and that is aimed at serial production. The days of using FBG sensors only for lab tests and R&D are over.”

Related Content

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More