INFINITE consortium tackles wireless sensor integration for life-long aircraft monitoring

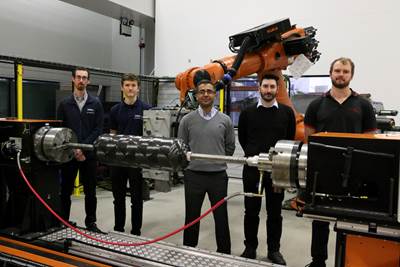

Engineers from University of Sheffield AMRC will support the embedding of highly specific sensors into composite aerospace structures for MHM and SHM and recylability opportunities.

Share

The INFINITE consortium, supported by engineers from the University of Sheffield Advanced Manufacturing Research Centre’s (AMRC, Catcliffe, U.K.) composites team, is to integrate wireless sensors — as thin as a human hair — into composite materials and embed them in aerospace components to monitor the condition of parts from manufacture to recycling, with the aim of extending their life span, improving quality and reducing cost.

The INFINITE consortium, funded by Horizon Europe under grant agreement No 101056884, was launched to tackle some of the biggest challenges facing the European aeronautics industry, like control of the aerostructures manufacturing processes and operating conditions, and bringing down components’ cost. The project, led by Spanish research center IDEKO (Gipuzkoa), a specialist in advanced manufacturing, is working toward developing a technology that will see wireless sensors incorporated into materials at the early stages of aeronautical structure manufacture. This will make it possible to track the entire life cycle of aeronautical structures, from on-site supervision of their manufacture and optimization of maintenance work, to thorough repair and service review through structural health monitoring (SHM) and recycling of parts at their end of life (EOL).

The package of works by the AMRC has been funded by Innovate UK. Composites research engineer, Fatma Omrani, is leading the AMRC’s involvement in the initiative for next-generation digital aircraft transformation in design, manufacturing, integration and maintenance.

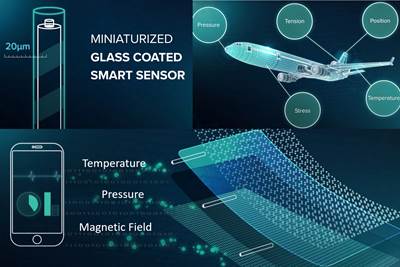

Omrani says INFINITE will be a game changer for the aviation industry. “Being able to integrate highly specific sensors into composite aerospace structures so early in the manufacturing process, and monitor the full life of a component, will represent significant progress in what we call manufacturing health monitoring [MHM] and SHM,” she says. “The early integration of these sensors and their wireless capability is a unique feature that is not currently available within existing solutions. It will provide means to manufacture higher quality components, as well as predict defects and damage more accurately. Imagine being able to tell if a part in the aircraft is safe without having to unnecessarily replace it as a precautionary measure?”

“This will be a game changer,” Omrani adds. “It will increase aircraft safety and component longevity, and reduce costs with predictive targeted maintenance, which will give a competitive advantage to [the] European and U.K. aircraft industries.

The AMRC composites team will combine its knowledge and expertise in SHM, dry fiber manufacturing and preforming, composites manufacturing and repair to support the project. The impacts of this project are reported to be substantial on the manufacturing of multifunctional and intelligent aircraft structures and will reinforce the AMRC’s leadership in these critical sectors.

The sensors to be used are based on magnetic materials and amorphous ferromagnetic microwires capable of reacting to electromagnetic radiation and will yield valuable information on the condition of the part at any time. These will be incorporated together with the dry carbon fiber, so they are embedded in the composite and their status monitored with a portable system to analyze the forces and temperatures to which the part is subjected and its condition.

According to Peio Olaskoaga, the technical coordinator of the INFINITE project, “The incorporation of these sensors at the very early stages of the life cycle will allow traceability of all subsequent stages of each component, and monitor their status with a non-invasive system to optimize their performance.”

To ensure INFINITE is meeting the needs of the industry, an advisory panel has been established consisting of experts from major players in the European aeronautical landscape.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

Twenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

Read MoreAMRC, industrial partners develop Type IV hydrogen tank for long-haul vehicles

In the 12-month project, the University of Sheffield Advanced Manufacturing Research Centre (AMRC) has built prototype tanks and worked to build a secure U.K. supply chain.

Read MoreContactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

Read More