Measuring temperature inside composites and bondlines

ThermoPulse sensors offer Industry 4.0 temperature measurement and digital cure cycle management for bonded composite repairs, laminates and more.

Share

Having full visibility into a composite and/or adhesive bondline during cure has been an issue for decades. Current temperature sensors — thermocouples — are too large to be embedded without causing a defect in the part. Thus, it is now only possible to read temperature at the surface and perimeter of parts and bonded repairs. It is difficult to know the temperature of an adhesive at the bottom of a repair patch, inside a thick fuselage or wing skin laminate or between those skins and thick stringers. Yet, that temperature is crucial for proper resin flow, wetting and cure.

Currently, the composites industry compensates for this shortcoming by spending months and millions of dollars testing to ensure that estimated time and temperature recipes do indeed complete cure and produce the necessary properties. Despite this, suppliers still spend many man-hours and dollars each year reviewing and certifying parts where thermocouples fail or where leading/lagging thermocouples are sufficiently outside of prescribed boundaries to cast doubt on properties and in-flight performance.

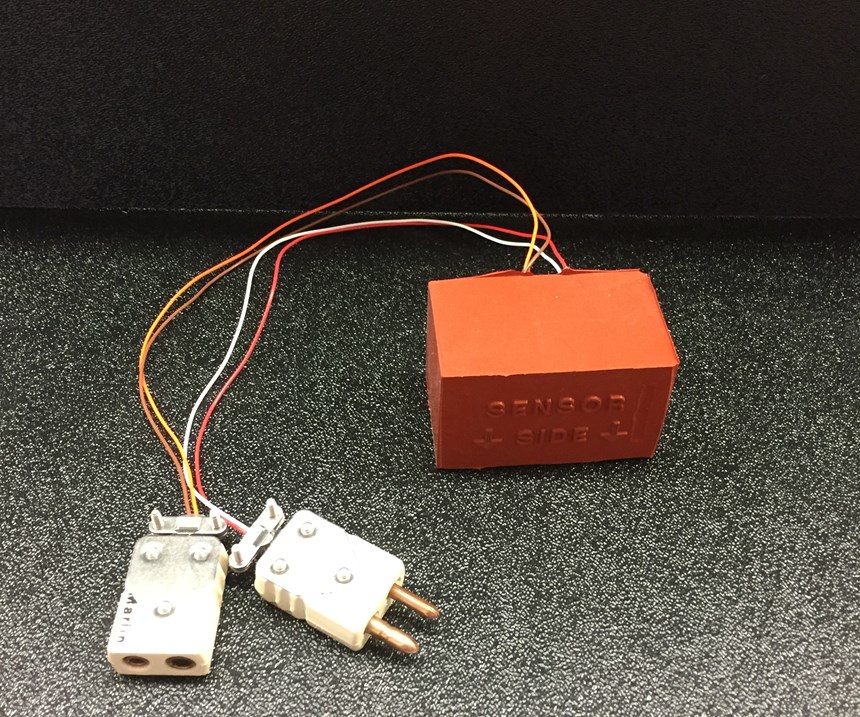

In an effort to solve this temperature-measurement problem, AvPro Inc. (Norman, OK, US) has developed the ThermoPulse system, which enables wireless, remote, in-situ temperature monitoring during cure. The system comprises microwire sensors, a transmitting/receiving antenna and a reader box that collects antenna signals and uses software to convert that information into temperature data. The sensors remain embedded in the part and the system can be used with autoclave, oven, infusion or resin transfer molding (RTM) processing. AvPro has already completed a Phase I Small Business Innovation Research (SBIR) program with the US Air Force and is currently performing a Phase II effort, directly measuring bondline temperatures during composite repairs and composite part fabrication and verifying the accuracy of ThermoPulse via round-robin testing at four independent sites.

The potential for this technology is significant, offering real-time Industry 4.0 data for not only thermoset composites, but also the temperature-dependent melt and crystallinity formation of thermoplastic materials. Further, measurement is actually not the system’s end goal. ThermoPulse ultimately will manage cure cycles based on the composite’s viscoelastic change. Cure cycles can be shortened because completion can be seen from real-time data vs. a legacy time/temperature recipe. Cure cycles also can be optimized, enabling the use of microwave and induction heating to deliver highly targeted and near-instaneous temperature as needed to achieve fast cure rates without “overcooking” the composite.

Macro vs. microwire sensors

Thermocouples are the most common temperature sensor used in composites processing today. Formed by two wires of different metals joined at one end, they generate a current with change in temperature. Thermocouples are inexpensive and can provide accurate temperature readings, but they must be plugged into a voltmeter. Even though the individual wires may have a very small diameter, the completed, data-generating assembly cannot be embedded into a part or bondline without reducing structural properties and also posing vacuum bag challenges (i.e., source of potential leak paths) which may lead to poor quality composite parts.

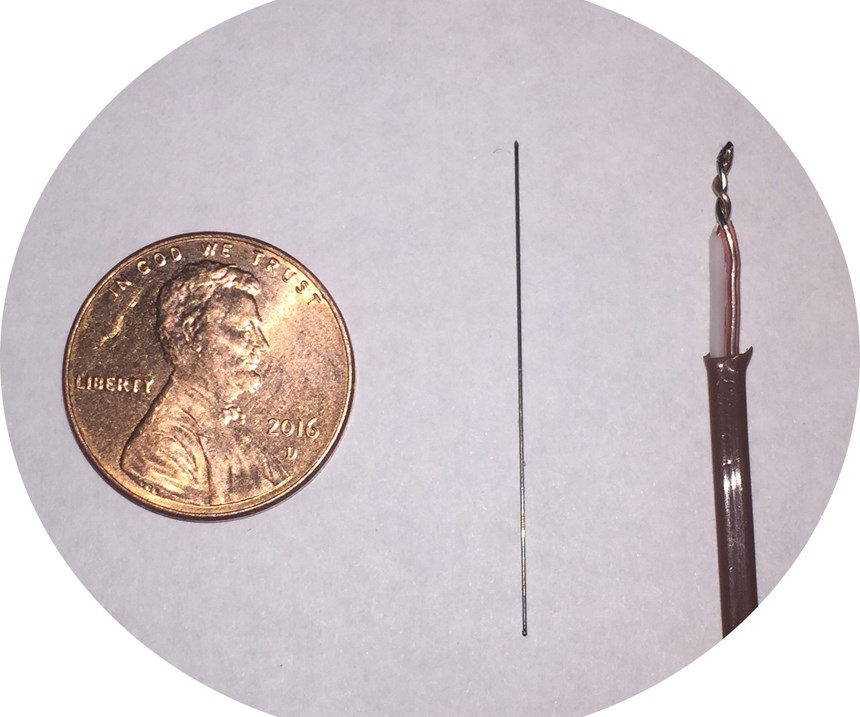

In contrast, the microwire sensors in AvPro’s ThermoPulse system are 0.25 mm in diameter and 32 mm long,and have successfully measured temperature while embedded beneath a carbon fiber-reinforced polymer (CFRP) laminate more than 25 mm thick. In lap shear test results, coupons with and without embedded sensors in the adhesive bondline are indistinguishable. The microwire sensors are made from amorphous metal alloys, mainly cobalt and iron. Their magnetic properties are unique. First, they polarize in only two possible states — along the wire length in one direction, or the opposite direction. Furthermore, the polarity changes nearly instantaneously — referred to as a Barkhausen Jump. When an alternating electromagnetic field is applied to a sensor, these Barkhuasen Jumps cause sharp voltage pulses that can be detected remotely with an antenna. The integral of each pulse is temperature-dependent.

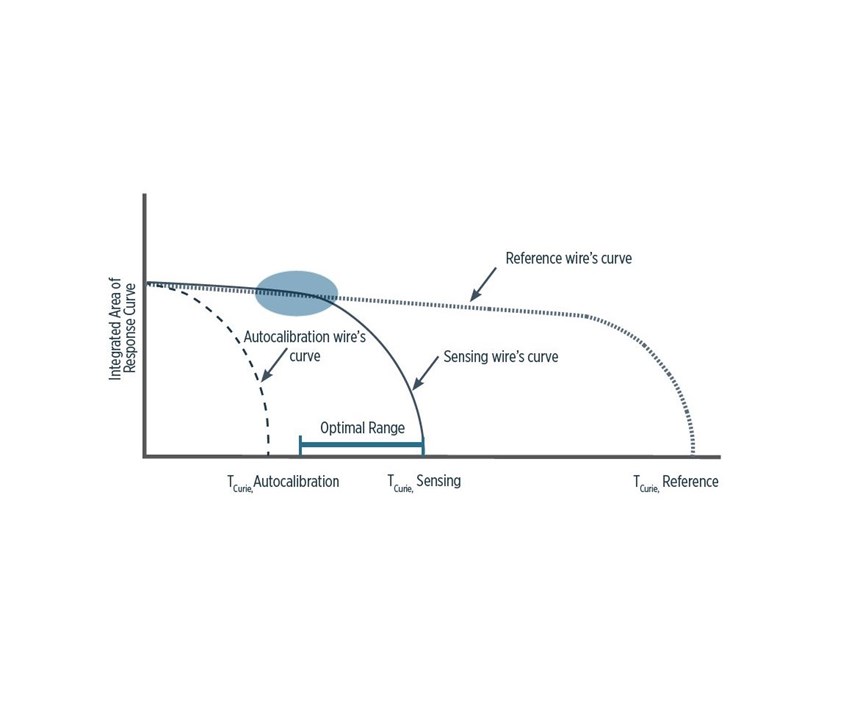

One more key component to this measurement mechanism is that the microwire metallurgy can be tailored to a specific Curie Temperature, which is the temperature above which the voltage pulse will no longer occur. Note, this is a certifiable physical property of the manufactured microwire. Precise temperature is able to be extracted from the microwire’s voltage pulse because the magnitude of the integral decreases nonlinearly as the microwire’s temperature approaches its Curie Temperature (Fig. 2).

Thus, the ThermoPulse antenna sends out a low-frequency electromagnetic field to interrogate the embedded sensor and then receives the resulting voltage pulse, which is then converted by the reader box into a temperature measurement at that sensor location.

ThermoPulse sensors are autocalibrating and are actually made up of three microwires encapsulated in a rigid tube. (It is the tube that is 0.25 mm in diameter; each of the wires is 0.03 mm in diameter.) One wire functions as the measurement wire and is alloyed to have a Curie Temperature approximately 50°F/10°C above the cure temperature for the resin system for which the sensor is designed. A second wire is termed the reference wire and is alloyed to have a Curie Temperature several hundred degrees above the desired dwell temperature, providing a constant pulse to normalize against. The third wire, called the autocalibration wire, is alloyed for a Curie Temperature above room temperature but significantly below the cure temperature. It will provide temperature readings until its known Curie Temperature is reached, at which point its pulse will disappear. At that instant, the temperature of the sensor is accurately verified and the ThermoPulse system has the calibration temperature needed to proceed with measurements and calculations.

SBIR Testing

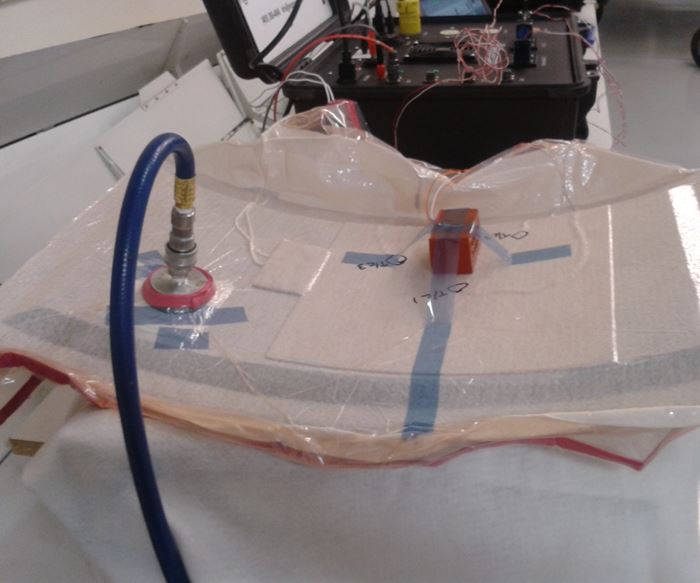

Having completed an initial Phase I SBIR with the Air Force to demonstrate feasibility, AvPro and its partners are now roughly halfway through the Phase II project, designed to validate the accuracy and precision of the ThermoPulse system. This is being achieved by testing at four independent sites, each using 25 ThermoPulse sensors and a prototype reader box incorporated into a type of hot bonder. Hot bonders are portable, small suitcase-sized equipment used to control the application of heat and vacuum to an adhesively bonded composite repair. The four test sites are AvPro’s facilities, Abaris Training (Reno, NV, US), TSI Technologies Inc. (Wichita, KS, US) and AFLCMC/EZPT-ACO at Hill Air Force Base (near Ogden, UT, US).

AvPro has worked with Abaris Training for years to help validate and refine its Material State Management (MSM) system, while TSI Technologies is a key partner in developing and refining the microwire sensors. Hill Air Force Base is home to the Ogden Air Logistics Complex, which performs depot maintenance on several Air Force weapon systems, and the Air Force Life Cycle Management Center’s Air Force Advanced Composites Office (AFLCMC/EZPT-ACO), a centralized resource for fielded composite materials. The research program is led by the Air Force Research Laboratory (AFRL, Wright-Patterson, OH, US) and project manager Kara Storage, with a view toward aircraft manufacturing and repair applications.

Each test site will complete 25 standardized bonded composite repairs using a 5-inch diameter scarf repair patch made from six plies of prepreg over a layer of film adhesive with a microwire sensor in the bondline. Each of these 25 repairs will also use thermocouples as a control for comparison with ThermoPulse microwire sensor results.

“We’ve completed all of the 250°F-cure repair tests and are now analyzing the data,” says AvPro president Tom Rose. “So far, the microwire measurements are within ±5°F of the thermocouple measurements.” Rose says all of the test sites are using CFRP laminates and patches except for Hill AFB, which has specific reasons for testing glass fiber laminates and repairs. “We are now starting testing with an additional 100 sensors for 350°F repairs and will complete the SBIR work by October 2019.”

Another goal of this testing is to develop the statistical basis for an ASTM method. ASTM International (West Conshohocken, PA, US) is an organization that develops industry standards, including most of the test methods used for composite materials and structures. “The ASTM method for measuring temperature in a bondline during composite repair would also apply to any composite bondline,” says Rose, “and will give the industry confidence in the accuracy of the ThermoPulse sensors.” Completing the repairs for the SBIR testing will also provide feedback for refining the hot bonder prototype as a closed loop temperature control device. “Our goal is to control the repair cure based upon temperatures within the bondline,” says Rose, “with the ultimate objective of providing significant time and cost savings.”

Modernizing cure, documenting quality

“This sensor was developed to feed into our cure management system,” Rose explains. “There really hasn’t been much fundamental change in the way we’re managing cure in composite structures.” AvPro’s material state control, however, is a significant change, which is one reason why its adoption has been slow. “The aerospace composites community is very conservative,” notes Lou Dorworth, longtime instructor at Abaris Training. “Using AvPro’s Material State Management system has required training and, initially, the units were not as user friendly as those being developed with ThermoPulse.” Rose acknowledges that the goal of current development is to have a commercial product that is easy to use. “We are also refining the software and scaling the wire and sensor manufacturing for industrial production. Currently, we are projecting a cost of $25-$30 for each sensor, which is roughly the same price as a thermocouple.”

“Our first priority is to get the technology finalized for commercialization and industrial production,” says Rose. He adds that AvPro will next move forward with establishing an ASTM test method; the final step will be to conduct whatever additional testing is required for structural certification (i.e., effects of defects programs). “Getting equivalent results with and without the sensor bonded in is a good start,” says Rose, “but structures engineers have to be convinced that the sensors can be placed at critical locations and improve their ability to achieve properties, without creating a defect.” His goal is to pursue an initial qualification of the ThermoPulse system at an all-composite light sport aircraft (LSA) manufacturer, which tend to have a flatter corporate structure than OEMs and large Tier suppliers.

Though change in composites aerostructures design and production is notoriously expensive and slow, there is more impetus now than ever to implement process control technologies that can accelerate the pace of composites manufacturing. Rose and Dorworth see the potential not only for aircraft manufacturing and repair, but for much wider applications such as managing temperature-dependent processes based on real-time, in-situ data. “Our system is giving the parts manufacturer the power to optimize its own cure cycles and correlate those to actual material properties,” says Rose. “We now have the ability to measure temperature and viscosity as a function of time in the part and bondline. That gives us the ability to truly establish digital control and have documented confidence in the quality of our parts.”

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More