Streamlining aerospace composites operations with RFID tracking

Tier 1 Sekisui Aerospace’s implementation of RFID tracking, sensors and Xemelgo software at two of its production facilities led to increased productivity, eliminating bottlenecks and reducing labor costs.

Share

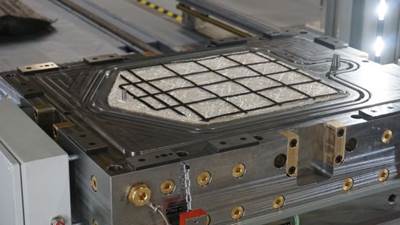

Automation can take many forms within a manufacturing facility. Xemelgo’s software, combined with RFID tagging technology, enables manufacturers like Sekisui Aerospace to automatically locate and track tools or parts within the facility, and sends automatic alerts via email if anything is delayed. A map dashboard system has also been developed to show visibility into parts’ progress across the facility in real time. Source | Xemelgo (top), Sekisui Aerospace (below, right)

Industry 4.0 and automation are increasingly part of conversations about part design and process, but there are also a lot of day-to-day operational tasks that are often done manually and with a heavy reliance on paper, such as tracking parts, raw materials or tools within a facility.

With this in mind, Rich Rogers and Akhila Tadinada, engineering and technology leaders who had previously worked together at digital technologies company Hitachi, decided to develop their own software platform for helping manufacturing companies automate operations tracking and similar tasks. In 2018, they co-founded their startup, Xemelgo (Bellevue, Wash., U.S.), and spent the next few years growing the business and entering pitch competitions to gain funding and recognition in the industry.

“Originally, [Rogers and Tadinada] started out with the idea that there’s more and more automation being used by manufacturers, but a lot of tracking and running day-to-day operations are still done on paper. There’s value to be created by automating routine, everyday mundane tasks, freeing up employees for more engaging work that adds real value,” explains Garrett Gross, Xemelgo product manager. “Every one of our solutions has been co-created with a customer, in response to solving customer problems.”

Over the past year and a half, the company has grown significantly, he adds. Xemelgo has partnered with radio frequency identification (RFID) tag and reader supplier Zebra Technologies (Lincolnshire, Ill., U.S.), which offers hardware that complements Xemelgo’s software. Xemelgo currently has customers deploying its technology across the U.S. in a variety of manufacturing industries, including Sekisui Aerospace (Renton, Wash., U.S.).

RFID tracking to streamline factory operations

Xemelgo offers a suite of software products designed to streamline various operations within a manufacturing facility, distributor or retail warehouse: Inventory management, asset tracking, work-in-process (WIP) tracking, shipment tracking and internal package delivery.

“We use a lot of different technologies to automatically collect data within a manufacturing facility, and the most prominent is currently RFID tags,” Gross explains. RFID is a common wireless tracking system that involves handheld or mounted sensors that use radio waves to connect to the microchips in RFID tags that are strategically placed on objects such as raw materials, tools, parts or shipments. All data received by the sensors is stored and translated into readable, actionable information by Xemelgo’s Cloud-based software platform.

Xemelgo’s software can be used with a variety of tracking technology, the most popular being RFID tags with handheld or mounted sensors. Xemelgo works with partners like Zebra Technologies to help customers install hardware. Source | Xemelgo

“RFID technology is popular because it’s simple to use, with no battery required, while providing a lot of advantages over a more traditional barcode system,” Gross adds. While barcodes have to be manually scanned within inches of the sensor, RFID tags can be sensed from 25 feet away or more and through materials like cardboard, and the scanners can communicate with hundreds of tags per second.

The Xemelgo app, downloaded on a smartphone or accessed via the web on a desktop, instantaneously provides real-time visibility on the location and/or progress of whichever inventory, part or package has been tagged and is being tracked. Operators can also input status updates, such as if a particular part is damaged or if it needs to be expedited for the customer.

Desktop and mobile platforms enable operators to look up inventory, parts, tools and other tracked items automatically and also automate tasks like finding missing items, taking inventory and keeping track of chemical or prepreg expiration dates. Source | Xemelgo

Ultimately, benefits include saving the time that it would take for manual searching or tracking on paper or other means, cost savings associated with this decrease in labor, increased productivity, an empowered workforce (as employees can see exactly what needs to be done next) and paper waste reduction.

Xemelgo’s software can be used for a variety of businesses where any sort of tracking of goods would be needed, including manufacturing, distribution and retail facilities, and for any range of end markets including aerospace, automotive and others that the composites industry serves.

In composites, the products with the most use cases are Xemelgo’s work-in-progress tracking platform, which can be used for automated location tracking and process management of current work orders via a real-time dashboard; asset tracking, which can be used to locate equipment or production tooling; and inventory management, for keeping track of expiration dates or shelf-life of prepregs, chemicals or other raw materials.

Composites case study: Sekisui Aerospace

One example of Xemelgo’s software in use for the composites industry is the company’s ongoing work with Sekisui Aerospace, a Tier 1 aerospace supplier of high-volume composite parts and assemblies. (To learn more about the work they are doing, see CW senior technical editor Ginger Gardiner’s plant tour of Sekisui Aerospace’s Renton and Sumner, Washington, and Orange City, Iowa facilities).

As Gardiner reported in 2023, Sekisui Aerospace’s product mix is wide-ranging, including 10,000 parts/year for aeroengines, 150,000 parts/year for commercial aircraft ducting and interiors and 100,000 carbon fiber-reinforced thermoplastic composite brackets per year. Manufacturing capabilities include prepreg layup with autoclave and out-of-autoclave (OOA) cure, compression molding for serial production including with high-temperature materials, quick prototyping and continuous compression molding (CCM) or automated stamping for producing thermoplastic composite parts.

The company began focusing on automation and Industry 4.0 practices when CEO Daniele Cagnatel joined the company in 2017. “We took a problems-based approach, wanting to modernize and update our processes in ways that make sense and could be standardized across the facilities, and this led us to start early on with the plaster shop, which ultimately led us to Xemelgo,” explains Julie Traweek, senior product manager and experience designer at Sekisui Aerospace.

Phase 1: Shipment tracking of plaster molds

Single-use plaster molds are made in a dedicated shop and then delivered a few miles away to the company’s Sumner production facility, where they are used to manufacture composite prepreg parts such as aircraft ducts (see the plant tour for more on this production process).

These molds are pretty fragile, says Traweek, “so they can break in transit or in the layup room fairy easily. But these molds are also the first stage of the process, so if there’s a delay with one of them for any reason, it holds up the process. Communication about plaster status is very important, and we needed a better way to do that.” Previously, a team of people was dedicated to locating molds and their status in the facility, and there was a list of roughly 600-800 missing plaster molds per month.

Traweek says that Sekisui Aerospace started investigating various methods for location tracking, including barcode stickers, and through this research process began working with Xemelgo’s software and RFID technology in 2019. “We knew that we wanted a process that would be easy to implement without too many added steps, but we also knew that we would want a solution that we could expand its use beyond plasters,” Traweek explains. “Our leadership’s ultimate vision, in fact, was to create a map to see every part located in the facility at once, and we thought RFID tags could be the way we could work toward that.”

Sekisui Aerospace first needed an automated solution to solve issues with missing or delayed plaster molds (blue, top photo) used to make a variety of ducts and other components (bottom photos), with the goal of finding a solution that could also scale up to automate parts tracking at its production facilities. Source | Sekisui Aerospace

For this first phase of deployment, RFID tags would be attached to each plaster mold at its manufacture. Each batch is scanned first by a mobile phone as it is loaded onto an assigned cart for transport out of the facility. As the cart exits the facility, the molds are scanned by readers at th shop exit — at which point each mold is labeled as “in transit” in the Xemelgo software — and then scanned again by a second reader on arrival at the Sumner plant.

Renuka Agrawal, director of engineering at Xemelgo, explains, “At the Sumner plant, there is an employee using a handheld scanner to do this, so that they can also do a visual check and take notes directly into the software using the scanner if there is visible damage or any other issues that need to be reported.” Automatic alerts send emails if anything is reported missing or damaged, and an email notification is sent to the team lead each day detailing all of the molds that were delivered that day and any recorded notes.

Traweek adds, “It was definitely an iterative process. We leaned pretty heavily on Xemelgo for getting the hardware installation and getting connected with the suppliers, and they were able to offer a lot of advice about how to approach this from their experience.”

Agrawal emphasizes that this process is not a huge departure from the paper system that was already in place, and isn’t meant to be. “At Xemelgo, we don’t want to disrupt the process that is already in place. We want to build a solution that is not a huge burden on the customer to put into place, and simply streamlines and automates the current system,” she says.

How did Phase 1 go? The list of missing plaster molds was reduced to less than 10 per month, Traweek says. Plus, the shop is able to produce more molds per day, as the staff who used to spend a lot of time looking for molds are now able to spend more time problem solving and leading their teams.

Once it was established that the technology was beneficial, Sekisui Aerospace began working with Xemelgo to expand the system to the rest of the Sumner facility’s operations.

Phase 2: WIP tracking

“In early 2021, Xemelgo began working with Sekisui Aerospace’s Sumner facility to implement the second phase, work order [or work in progress/WIP] tracking,” Agrawal says. “We started with one operation to begin with, and then once we had that up and running, we rolled it out across the entire facility.” The goal was to solve similar issues with locating parts in progress on the floor, and to also create a solution that could be standardized across facilities.

An RFID tag attached to each plaster mold or part being tracked can be read by wall-mounted sensors to track when they arrive in different facilities or areas of the facility. Source | Sekisui Aerospace

Implementation was again an iterative process. As prepreg materials are cut and kitted for a part, each kit is fitted with a removable RFID tag. This kit can then be tracked as it moves through the facility to the layup area. Once laid up onto one of the single-use plaster tools described above, the kit’s RFID tag is removed and is attached to the top sheet of its paperwork order that follows it through the facility for the rest of the process. “It goes from layup to bonding, bonding to where the single-use plaster tool is broken out, then to trimming and assembly, and finally to final part storage before it gets shipped out. The same tag that was associated with the prepreg kit follows the work order around the facility to shipping,” Agrawal explains.

To accompany this process, 120 RFID readers were installed around the facility — “We basically blanketed the entire facility with RFID readers,” Agrawal says. These allow the work orders to be scanned and tracked at all locations and operations, enabling visibility of all steps in real time without having to rely on manual scanning of barcodes. “This eliminates any question of trying to figure out where a particular order is at,” Agrawal says, noting that Sekisui again had previously had to devote multiple employees to finding orders on the facility floor.

Traweek adds that one challenge during this phase was that the company was in the process of updating its ERP software, so the system had to be able to work with both the current system and the future upgraded version.

Gross says that the Xemelgo platform was able to integrate with any ERP system, and that it works hand in hand with it to automate real-time data collection, rather than competing with or replacing the current system.

It soon became clear that this use for the WIP tracking product required a more sophisticated tool to locate parts and manage efficiency expectations around the plant more easily. The companies began working on prototypes of a plant-wide map system that Sekisui’s leadership had envisioned.

Developing a dynamic, real-time map dashboard

“From a leadership perspective, Sekisui wanted a bird’s eye view of how the facility is doing,” Agrawal explains. For a company that produces hundreds of thousands of parts per year, being able to quickly see the overall status of the plant was paramount.

With Sekisui’s help and feedback, Xemelgo developed a map tool accessible within the Xemelgo WIP tracking platform, which gathers data from the work order RFID tags to provide a color-coded “bird’s eye view” of where all orders are at within the facility at any given time.

The map dashboard system enables both operators and leadership to see the progress of parts around the facility in real time. Source | Sekisui Aerospace

“The color codes are based on time of each part or material kit in each location, compared to the input data of how much time each part should be at each place for each operation,” Agrawal says. Xemelgo worked with Sekisui to determine the timing threshold for each operation — both the ideal timing and the allowable timing — to account for any queuing or other regular holding periods.

Areas of the facility that are operating within the programmed time threshold for a particular order are color coded green on the map; yellow areas warn that a threshold has been reached and red indicates the threshold has been exceeded. The map dashboard can also be filtered to show only orders marked as expedited, or to show only orders being manufactured for a particular part. For the latter, a report can be produced that Sekisui can use in its conversations with customers. “We’re still working on this feature as well,” Agrawal adds. “In future, we plan to build a secure customer portal where customers will be able to directly access data from their orders on the factory floor.”

“It vastly expands on the picture you get with just an ERP system,” Traweek says. “It sheds light on so many of what I’d call ‘black holes’ in the process, or areas where you just really don’t have any visibility.”

Developing the threshold system was an iterative process, Agrawal adds. Because this was not data Sekisui had access to before, “the original thresholds set just to try it out were of course very optimistic, based on ideal scenarios. And almost immediately, every area of the facility was yellow or red. Because the reality is, there are a variety of reasons that a particular part may not be worked on at any given moment. This could be a material shortage, or an issue that an engineer is looking into, or some defect or a change in the process. We learned there are a variety of known reasons why a part might not be worked on at a given moment, and the whole department shouldn’t be penalized for this.”

Xemelgo was able to introduce a feature where Sekisui employees can “report an issue” on any particular work order, which excludes that part from appearing in the map dashboard for a period of time. Xemelgo also worked with Sekisui to determine an accepted threshold for how many parts may be out of process at any given moment, so that the entire map doesn’t turn red because a small percentage of parts appear to be off-schedule at any given time when they are within a reasonable and expected amount.

One of the unexpected benefits of Xemelgo’s system for Sekisui Aerospace was an increase in productivity. Automating parts tracking enabled employees who used to spend more time manually looking for parts and plaster molds to spend more time on the production floor. Source | Sekisui Aerospace

Gross adds, “The colors can be very motivating to people. Nobody wants their station to be red. This is a program where every single operator at the facility can look at the TV and see how their department is doing at any given time. And just by having that metric up on the board increases performance. We didn’t change Sekisui’s process, we just added more visibility into what is going on.”

According to Agrawal, production increased by 3% at the Sumner facility when the technology was deployed. But an increase in production efficiency wasn’t the only benefit. Gross points out that workforce development and the challenge of hiring skilled laborers is an industry-wide problem in manufacturing, and a software system like Xemelgo can help alleviate these issues. In Sekisui’s case, Agrawal notes, “Cagnatel really believes in enabling people to use their skillset to the fullest potential. And that’s really our goal as well, using technology to do mundane jobs like locating molds and parts in progress so that the people who were doing that can do higher level jobs.”

As noted in CW’s plant tour on the company, Sekisui’s Sumner facility was able to reduce the staff needed to locate parts within the facility from 15 to three once Xemelgo was deployed.

Currently, the Sumner facility has gotten to the point, Traweek says, where they’re able to use the Xemelgo system to help not only achieve visibility into the process but to also help inform optimization of the process as needed.

Phase 3: Replicating at Renton

Once the Xemelgo technology was shown to be effective at the Sumner facility, Sekisui decided to replicate the system at its facility in Renton, Washington.

Similarly to the Sumner plant, about 120 manual or handheld RFID readers were set up around the facility, and a process was put in place to track works in progress from material cutting and kitting through to the final part ready for shipment.

The system was up and running as of April 2024. Traweek notes, “Right now we’re knee-deep in deployment, tuning, reader adjustments, process adoption and all of that. Renton is different in that it doesn’t have that same mix of parts that Sumner does. It’s where our design center is, so most of the new programs flow through Renton and customers are involved, which opens up new possibilities and things to think about.”

Continuing developments: Customer portal, core tracking

Xemelgo continues to work with Sekisui to offer additional software features for its Sumner and Renton facilities. These include exploring the concept of the aforementioned customer portal option to the WIP map dashboard, as well as extending the RFID to track metal tooling like jigs and fixtures and also core, which, similarly to the single-use plaster molds, is produced at a separate facility and then shipped to Sumner for use in the manufacturing process.

Xemelgo is also working on integrating its platform more fully with ERP systems such as Epicor, which Sekisui uses. At first, there was an additional process involved with transferring data from Epicor to Xemelgo, “but we’ve integrated the systems so that tracking information is automatically updated in our system,” Agrawal says. “Now, we are working on enabling a path back to their ERP system, so that they can use Xemelgo’s data to do things they would use Epicor for, like prioritizing queues on the floor.”

Additional use cases: Inventory tracking, raw materials management

While Sekisui Aerospace is a key early user of Xemelgo’s software in the composites space, this technology has been successfully adopted in a variety of related industries, and the company sees a lot of potential for other future uses as well.

For example, Xemelgo’s asset tracking feature, which leverages RFID tags to manage a variety of assets, has been successfully deployed by customers such as an automotive manufacturer tracking thousands of returnable totes, a metal forming shop tracking production tooling, a bond shop specializing in metal-metal bonding for the aerospace industry and an industrial distributor of supplies and chemicals.

With RFID inventory management, “You can automatically track consumption and manage optimal stock levels, and then we can alert you in time to let you know that you are running low before you completely run out, so that you can avoid downtime while saving on expedited costs or transportation,” explains Gross.

Another potential Xemelgo use case within composites is to manage raw materials inventory. “There’s a lot of potential there for composites manufacturers, to be able to track prepreg life and send out alerts if material has been out of the freezer too long or is reaching its expiration date or whatever the parameters are that have been set for each material,” Gross says. “In composites, this could help with compliance use cases, such as tracking the shelf life of prepreg.”

Agrawal adds, “You can do a similar process with chemicals that are used in composites manufacturing. You can track the expiration time on it to alert you on the right time before it expires for you to take action. It can save a lot of chemicals, help you see what needs to be used at the right time and help you to both remain compliant and also to eliminate waste.”

AI and continuing innovation

In the case of Sekisui Aerospace, “They’ve come a long way for sure,” Agrawal says. “They’re confident with the Xemelgo technology, and they’ve been able to use the data it provides to iron out a lot of different wrinkles and improve their own processes as much as possible.”

In addition to continuing developments with Sekisui and other customers, Xemelgo is always working internally on new tools as well. One of the next big advancements to roll out will be an AI feature, Gross explains. “We’re developing AI-powered dashboards that will not only combine all of this information from the ERP plus real-time data from Xemelgo’s RFID system — as we do now — but to take it a step further and use AI to provide insights and help inform decisions. We’re also piloting an AI-powered chat, sort of like a ChatGPT type of experience, where leaders at a company or even customers could ask questions like ‘Which Boeing orders are in my layup department?’ and the chat will answer it automatically and securely.”

“The bottom line is that we’re not done innovating,” Gross adds. “Our team continues to build these tools out, by spending time on the factory floor with our customers. Sekisui is a great example of how our technology works in the composites industry, but also more generally of how when we all put our heads together with our customers, we can develop incredible solutions.”

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Kanfit coping with COVID-19 and managing growth using Composites 4.0 systems

Bluetooth sensors and AI track parts and tools, save time and suggest production line improvements.

Read MoreiComposite 4.0 — cutting composites cost by 50%

An intelligent, integrated process using 3D fiber spraying, inline inspections/simulation and embedded RFID chips to cut scrap and rejections for structural HP-RTM epoxy parts.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read More.jpg;width=70;height=70;mode=crop)