Kanfit produces a wide range of composite parts and hybrid assemblies, such as this UAV engine cowling, in its new, 12,000 square meter facility in Israel. SOURCE for all images | Kanfit Ltd.

As I prepare an article on digitizing composites production for our July issue, I interviewed Shachar Fine, EVP of business development, marketing & sales for Kanfit Ltd. (Nof-Hagalil, Israel), a high-growth, diversified composites manufacturer and aerospace tier supplier. CW briefly mentioned Kanfit’s use of Bluetooth sensors in our 2018 series of plant tours in Israel (see “Thriving pioneer in aerospace builds business …”). In this blog, I will explore this artificial intelligence (AI)-based system in more detail.

Coping with COVID-19

But first, Shachar Fine and I briefly discussed how Kanfit is dealing with COVID-19 and maintaining composites production. “The Israeli government has issued directives that certain ‘non-essential’ businesses must close (e.g., gyms, salons, etc.),” he explains, “but those defined as ‘essential’ (e.g., COVID-19 and healthcare supplies, food, etc.) can work at any rate as long as employees stay at least two meters apart. The defense industry can have up to 50% of its employees and remaining industry can have up to 30% of its workforce, as long as these companies abide by the distance requirement.”

“We are bringing in up to 50% of our employees per shift and running two shifts,” says Fine. “A third shift never justified itself because the productivity was just too low. Even now, we won’t do that. But we are extending some of our shifts. For example, in departments such as machining, where employees are mostly monitoring automated equipment, we will run 12-hour shifts. But for departments where workers are performing more manual tasks, we will run shifts of 8-10 hours.” He explains this is basically to help offset the loss in productivity due to the required social distancing.

Fine indicated that he would like to hear how other composites manufacturers are adapting. “I’m sure I could learn from what composites factories in other parts of the world are doing. I’m in a Business Development Group on WhatsApp here in Israel and we share advice on how to continue business development when you can’t meet or travel. Of course, the priority is to keep everyone safe and healthy.”

Bluetooth vs. RFID system

As explained in the 2018 tour article, the system Kanfit installed was supplied by a Tel-Aviv start-up, Trekeye. The system comprises Bluetooth (wireless) tags that are attached to each part’s traveler, meaning the work order that travels with the part.

In Kanfit’s part tracking system, a Bluetooth tag is attached to each part’s work order that travels with it through production.

When the work order for a part is printed, the tag is attached to it and then delivered to production. For composite parts, the next steps could include automated cutting and kitting of prepregs or dry reinforcements, layup, preforming/debulking, resin transfer molding (RTM) or vacuum bagging and autoclave cure, trimming, nondestructive testing (NDT) and painting. Typically, there are multiple inspections in between these steps. The process chain could also include assembly with small and large metal parts into larger modules. Producing such modules, including installing various systems (e.g., wiring, insulation, distributed power, etc.) is a growing trend for aerospace tier suppliers. Once the process chain is complete and the part/assembly is ready to ship, the Bluetooth tag is removed and reused on a new work order.

Fine explains that these are tags, not sensors. “A tag doesn’t sense but just transmits a signal,” he notes. In this case, each of the Bluetooth tags transmits its serial number every 10 seconds. “Antennas receive these signals and triangulate the position of each tag,” says Fine. The final system component is the software, which collects the data, applies algorithms to analyze it and responds with alarms and/or suggested actions. The Bluetooth tags are battery-powered, but the software alerts when the batteries are low on charge, and the batteries last for more than a year.

Composite parts produced by Kanfit Ltd. include (clockwise from top left) carbon fiber/epoxy louvers, quartz fiber/epoxy SATCOM radome, autoclaved wing-to-body fairing, carbon fiber/epoxy duct, 1.6-meter RTM folding wing and UAV wing tips.

Kanfit explored using RFID tags, but because they use radio frequency (electromagnetic fields) to transmit data, metal interferes with the signal. “We have a lot of metal in our production environment,” Fine explains. “So, you have to think of where to put the RFID antennas in the building so that each tag’s signal is always received. If the RFID tags periodically don’t register, then the entire data stream is compromised. With our Bluetooth tags, we proved 100% registration. We threw them in with metal parts and put them near different antennas. Every time, the system picked up 100% of the tags.”

Another difference, he explains, is that the Bluetooth tags are active, sending out a signal, while RFID tags are typically passive — their signals only get picked up if they pass by an appropriately situated antenna. “With the Bluetooth tags, you position antennas where you want the system to report parts,” says Fine. "So there is no technological restraint like with the RFID system. You can put the antennas on a wall, ceiling or a work station. Where you place them and how many you use in an area is a matter of what resolution you need. For example, in a waiting area, one antenna on the ceiling is sufficient, but in an area with several process steps, you may need multiple antennas.”

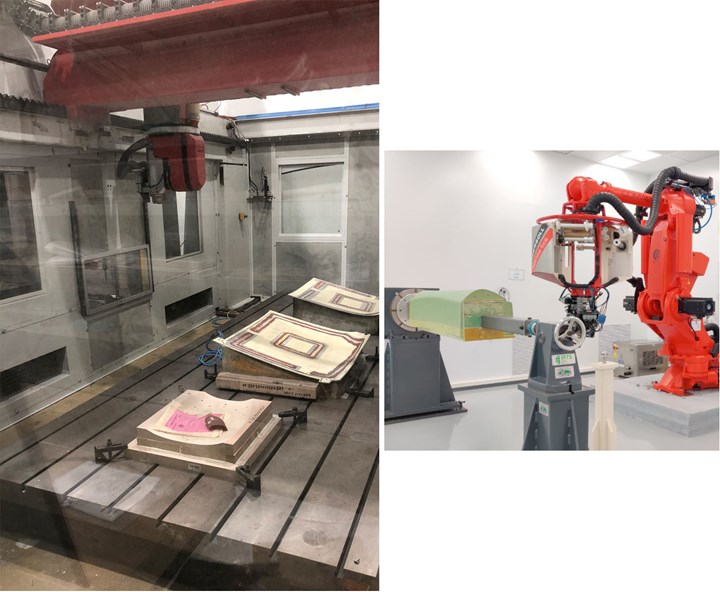

Kanfit worked with Trekeye to place Bluetooth antennas on production area walls, ceilings and work stations, based on the process steps it wanted to monitor and resolution it required. Bluetooth tags were placed on part work orders as they began in materials cutting (bottom left) and layup (top left), and then tracked these as they proceeded through each part’s process chain, which could include retrieval of fasteners from automated parts storage (top right) and progress through various departments and holding areas.

One disadvantage of the Bluetooth system Kanfit installed from Trackeye is cost. “There is a lot of infrastructure,” says Fine, “and these Bluetooth tags cost dollars, not cents like RFID tags.” There was also a significant development requiring Trekeye developers to be onsite. “They helped us to locate the antennas so that the information we collected was optimized for what we were trying to achieve,” he explains. “They taught us how to address issues with overlapping areas of antennas so that the system is not confused by one tag being read by two antennas at the same intensity. It was a process.”

Part maps and spaghetti charts

Once the system was installed and running, the results it returned included part maps and spaghetti charts. “Our IT department had the online map open for the system all the time,” Fine explains. “When a worker was looking for a part, they went to IT, quickly located the part and then went to retrieve it in the plant. It was very easy to see where all of the parts were.”

He explains that Kanfit has thousands of parts all over the production floor (3,000 open work orders every minute), “and it’s not a standardized assembly line. The mix of parts being made changes and some parts require different steps than others. For example, not every part gets autoclaved or machined. When you see a part, you don’t always know if it’s in the right place. You need to check the part's paperwork to understand that”

The Trekeye system, however, worked amazingly well. “Even though it was not a cheap system, the ROI (return on investment) was very short,” says Fine. “The system has a very advanced AI. It didn’t wait until a part was missing. It would send an SMS (text message) to the manager that “ABC” part went to the wrong station. There was no waiting. The system would alert when a part didn’t follow its normal route.”

These part routes or paths are shown on what is called spaghetti charts. “These show the paths of the parts through our factory and process chains,” says Fine. “We were starting to see trends. For example, as engineers created the work orders for parts, they would put in inspection steps according to their knowledge and experience. Parts would go first to inspection before moving to the next station. The spaghetti charts would show that you could change some actions and reduce the distance that parts were traveling. We would see a part going back and forth between departments for multiple actions. We’d then sit with engineering and ask why is it going back and forth? How could we reduce four times down to two times, for example? This is easy to see in the chart but hard to see in actual day-to-day operations on the floor, and also what the actual effect of that back and forth is on overall production. You can see the steps as line items as you write them in the work order but to see the paths in the spaghetti chart is more data and a visualization of that data that has real impact.”

“This also helped us as we have moved into our new, larger facility,” Fine adds. “One of the lessons we learned is to centrally locate the inspection department within the production area. So, over time, I am sure the AI would continue to help us to better locate machines and stations, and even as our parts and operations change over time. It can also track tools.”

Kanfit’s Bluetooth tag system provided guidance as it moved into its new facility, to centrally locate the inspection department within the production area to shorten travel distance and overall cycle time for parts and assemblies.

Another benefit is that Kanfit could track how much time a part spends at each station. “Though we haven’t yet implemented this, it could reduce the time employees spend entering such data,” Fine notes. “We still have an ERP system that the employees report into, but the Bluetooth tag system gave better detail of when a part entered and left a station, etc.”

Fine notes that these part and tool monitoring systems don’t replace the ERP but must be integrated to work with it. “We keep developing our ERP system in-house because we have big customers and every one of them has their own requirements. So, we have to develop a lot into our system in order to provide all of the information that each customer wants.” But he sees the power of the Bluetooth tag/AI technology to improve these systems, and the advantage in further efficiency that offers.

No data entry

Did you have to enter a lot of data for each part when you created the work order and attached the sensor? “No, that’s the most amazing part,” says Fine. “There was no data entry. It’s the AI system. All it received was the work order numbers. These comprise letters and numbers, but there is a kind of logic to the way we come up with these and what they mean. The AI must have learned this. Once it started to gather data, it learned where the parts should be. For example, all “ABC” work orders were metal only and never meant to go to the composites department. So, when a metal part went to the composites department by mistake, the system alarmed. Even the AI designers were surprised at how quickly the system learned. We initially tested 100 parts. It learned within this first batch.”

Fine explains that this is what the system was designed to do. Trekeye started in hospitals, working with a mobile medical device maintenance company that helped maintain blood pressure cuffs, thermometers, monitors, etc. That company complained that they were spending 80% of the maintenance technician’s time just looking for the devices that needed maintenance. “With this system in place, the technician would come in, connect to the system and see exactly where all of the devices were in the hospital,” says Fine. “An added benefit was that theft went down. Whenever someone would walk out with a device, the system would alarm and a security officer would be sent down to retrieve the device.”

Future implementation

Unfortunately, Trekeye did not make it through the critical “Death Valley” stage as a startup, and is no longer operating. “We have everything we need to keep the system running except for someone to oversee it,” says Fine. “For this kind of system, you can’t just have a general IT person. You need someone very proficient in AI. We are also just finished moving into our new facility and haven’t re-initiated the system yet.” He has searched for another company doing something similar but says he hasn’t found anything that meets Kanfit’s needs yet. “We will find a way to get it back into operation again soon,” he adds.

So, what is the real benefit? “First, whatever you can’t measure, you can’t manage,” says Fine. “Second, the amount of data we have is so huge, even for us as a small factory, that we’re past the point of having one or more persons to be able to deal with all of this data. I can’t even imagine what this must be like for Boeing or Airbus. We have to have the machines talk to each other now. Let them do what they’re good at and let us humans look at the big picture and develop new solutions based on what they can show us.”

Stay tuned for more blogs on Composites 4.0 and CW’s feature article in July.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More