ACoSaLUS project develops fully automated FPP layup for legacy sandwich parts

Joint R&D project results show 7 times improvement in layup rates, reduced material deployment and development of novel layup features when using FPP for aerospace production.

Source (All Images) | Cevotec GmbH

Following successful completion at the end of 2023, Cevotec (Munich, Germany) has presented the final results of the ACoSaLUS joint R&D project, which sought to develop and test an industrial solution that accelerates the production process for sandwich composites. Efforts targeted aerospace manufacturing, which is still characterized by parts that are produced manually at high production costs and with limited scalability.

Together with partners GKN Aerospace Deutschland, material supplier SGL Carbon, TUM – Chair of Carbon Composites and Technical University of Applied Sciences Augsburg, the project advanced the basis of Cevotec’s fiber patch placement technology — it is capable of laying up different type of materials, from structural (carbon fibers) to auxiliary (glass fibers, adhesives), onto a 3D tool to produce complex aerospace parts with one single machine setup — and introduced new layup features.

To quantify the consortium’s goal of proving (via automation) that legacy parts can remain financially viable and production rate increases in the aviation market can be met, the project team set an ambitious target to demonstrate a layup rate increase to 15 square meters/hour for a reference part.

A horizontal tail plane (HTP) fairing was selected. On aircraft, it protects and shields the structural attachment of the horizontal tail to the empennage. This legacy part features high geometric complexity and a sandwich structure that combines monolithic skins and film adhesive with a Nomex honeycomb core, making the manual manufacturing complicated and time-consuming.

The HTP fairing has put previously developed FPP capabilities to a test and called for the development of new features in order to perform the demonstrator production according to specification. The following table summarizes key FPP features deployed in the actual demonstrator

layup:

|

Key feature |

Status |

Description |

|

Zonal suction |

Commercially available |

Independent suction zones inside the gripper to enable rolling motion layup. |

|

Advanced rolling motion |

Commercially available |

Draping the patches with a rolling movement of the |

|

Post placement push-in |

Commercially available |

Use of the patch-gripper to further push the patches/plies in areas of complex features. This features imitates a typical manual layup operation. |

|

Post-placement vision inspection |

Prototype tested, in further development |

Additional patch inspection with a robot-mounted camera to ensure placement according to program. Image analysis used neural network algorithm. |

|

Honeycomb gripper |

Prototype tested, in further development |

Mechanical gripper able to grab honeycombs without causing any damage, e.g., by needles, and to transport and place them onto the tool. |

The combination of the above features enabled the production of five demonstrator parts, validating the capability of FPP in automating the manufacture of legacy parts. At the same time, the mechanical performance of the part was not compromised. After performing bending tests in accordance with the OEM’s requirements, the FPP parts showed 25% improved deflection at an increased material deployment of less than 10% due to planned overlaps. In addition to the increase in mechanical performance, layup time also was significantly reduced by efficient FPP layup.

In conclusion, the project was successful: patch layup was performed fully

automated and the option to remove intermediate debulking steps was confirmed. As a result, the project team reached the initial goal to of speeding up the layup process. Skin layup showed the potential to increase the layup rate by factor >7 times, from 1.5-2 square meters/hour (reference process)

to 14.5 square meters/hour via FPP. Additionally, critical stiffness was increased by 25% with only slightly increased material use.

By making the technologies and strategies developed in this project available to FPP users, this project can serve as a blueprint for further automation activities within legacy aircraft programs as production rates continue ramp up.

This post is courtesy of the CompositesWorld and AZL Aachen GmbH media partnership.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

HyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

Read MoreBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

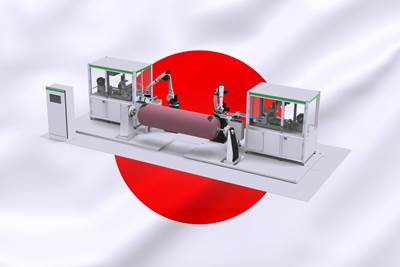

Read MoreFuji Industries purchase brings FPP-based Samba Pro PV to Japan

Dedicated to the production of hydrogen pressure vessel reinforcements, Cevotec’s specialized FPP system will be made accessible to Japanese industry through Fuji, including aerospace and composites research.

Read More