Techni-Modul Engineering grows automated technologies for composite part manufacture

New processes and approaches for kitting, stack and layup continue to be in high demand for composite industry OEMs, which TME backs with its SMART Control technology.

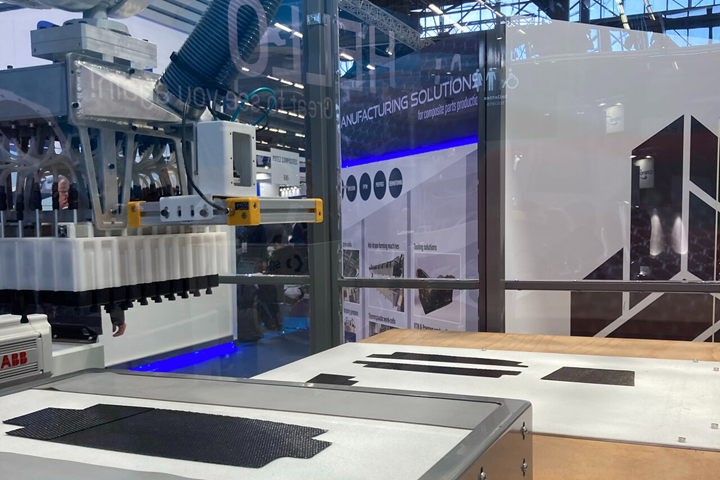

The SMART Control system, as seen at JEC World 2023. Photo Credit, all images: Techni-Modul Engineering

Founded in 1986, Techni-Modul Engineering (TME, Coudes, France) specializes in the design and realization of robotized, automated and innovative composite manufacturing solutions adapted to various processes. Its long history, from the manufacture and supply of molds for the plastics industry, and eventually automotive, under the Ordimoule name, to its 2008 merger and focus on equipment for composite part manufacture, including for aerospace OEMs, has brought the company and its team full circle with the announcement of TME’s automated layup SMART Control technology.

In the late 1980s, as the plastic injection market was quickly saturated, TME (at the time still Ordimoule) turned to technologies for processing composite materials. Early customers like Salomon in the sports leisure equipment market fueled TME’s growth. Aérospatiale, now Airbus, later entrusted the company with development of a complete mold set for the A320 cockpit, in addition to creating two resin transfer molding (RTM) tools in 1988, which were equipped with thermal regulation (heating/cooling) and automated opening/closing. Since 1990, TME has been a large supplier for automotive tools for molding speakers and thermal insulation (such as underbody covers and engine shields).

Techni-Modul was founded in 1996, primarily focusing on composite processing innovations, putting into shape new ideas to offer its customers more safe, reliable and efficient equipment. At the end of the 20th century, the company had designed and produced its first helicopter blade machine, which has been constantly improved over six generations with mechanical and thermal precision iterations. Thanks to Airbus Helicopters, Techni-Modul was able to initiate its first contact in China in 2006, a country which today represents a significant part of the company’s revenue stream.

SMART Control is said to guarantees the manufacturing quality, accuracy, repeatability and process times that must meet the need for more automation.

A patent was first filed in the early 2000s, which consisted of heating a metallic fluid by Joule effect, a process intended for very rapid heating/cooling (30°C/second), for the manufacture of tubular thermoplastic parts. Depending on part configurations, the system is capable of reaching a 2-minute cycle.

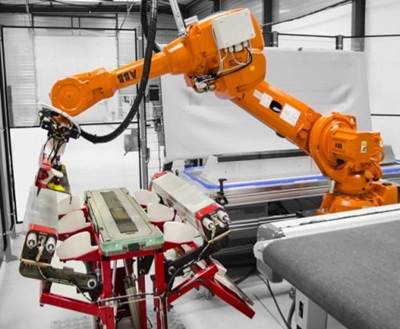

Techni-Modul Engineering (TME) was born in 2008 as a merger between Techni-Modul and Ordimoule. At the beginning of 2014, to be at the forefront of innovation, and driven by aerospace OEMs manufacturing technology improvement needs, TME started developing existing composite preforming steps by introducing intelligent automation to this process. SMART Pick & Place, for example, is a pick-and-place preform cell and an in-house developed control software with an algorithm system. It’s implemented using a camera and manages features such as ply recognition and orientation, material defect and FOD detection, fiber orientation checks and tool ply layup positioning. The innovation was recognized by CAMX and JEC Asia in 2016. SMART Pick & Place was operationally deployed in the aerospace industry that same year.

In 2015, subsidiary Composite Alliance Corp. was set up in Dallas, Texas, to establish an international presence to support TME’s growth in the U.S. At the same time, new 4.0 developments aimed to anticipate the future needs of the company’s customers under SMART solutions, which have been created to optimize production by reducing cycle time, increasing quality and repeatability and improving the work environment.

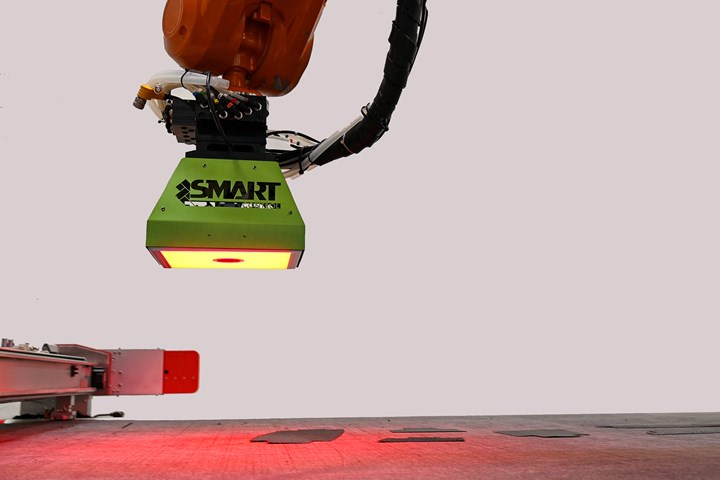

SMART Control is one such solution example, a marketable version of which was launched after several months of delay at the end of 2022. Culminating four years of research and development (R&D), the automatic control technology is said to enable users to check the conformity of the layup to the theoretical plan in real time. Its camera system, lighting and plug and play software allows control functions such as shape identification and recognition, fiber orientation control, ply positioning, gap and/or overlap detection as well as FOD and defect detection on composite materials.

SMART Control is said to guarantees the manufacturing quality, accuracy, repeatability and process times that must meet the need for more automation. It was initially developed for the aerospace industry but can also be introduced to any other composites sector in which high-rate kitting, stacking and preform layup of unidirectional (UD) or woven materials is required such as for aeronautic applications (Class 1 parts).

Key features include:

- 100% approved quality

- Identification and shape recognition (DXF matching)

- Control of fiber orientation with an accuracy of ± 0.3 degrees

- Control of the plies position with an accuracy of 0.25 millimeter (DXF matching)

- Detection of gaps and/or overlaps between two plies of the same layer (DXF matching)

- Detection of FOD greater than 3 millimeters in diameter

- Recognition of defects on composite materials.

Other SMART Solutions available to the composite industry include SMART Gripper, SMART Injection and SMART Pick & Place.

Today, TME is 100% owned by the Canadian public company Composite Alliance Group (CAG, Calgary Alberta, Canada).

“I would like to thank all our shareholders who have placed their trust in us, despite the fact that COVID has had a severe impact on the aerospace industry,” says TME CEO Serge Luquain. “We believe that the year 2023 will be much brighter as we continue to develop TME into a world leader in composites processing expertise.”

Read Next

Automated preforming: Intelligent automation in pick-and-place systems

Layups go industrial with hand-like grippers that can fold fabric or prepreg into corners and robot-mounted cameras that inspect from fabric to cut plies to fiber gaps in final preforms.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More