Arevo introduces 3D-printed carbon fiber unibody bike frame and rim

Arevo will display its 3D-printed carbon fiber unibody production bike frame and 3D-printed thermoplastic rim at Eurobike 2019.

Share

Source | Arevo

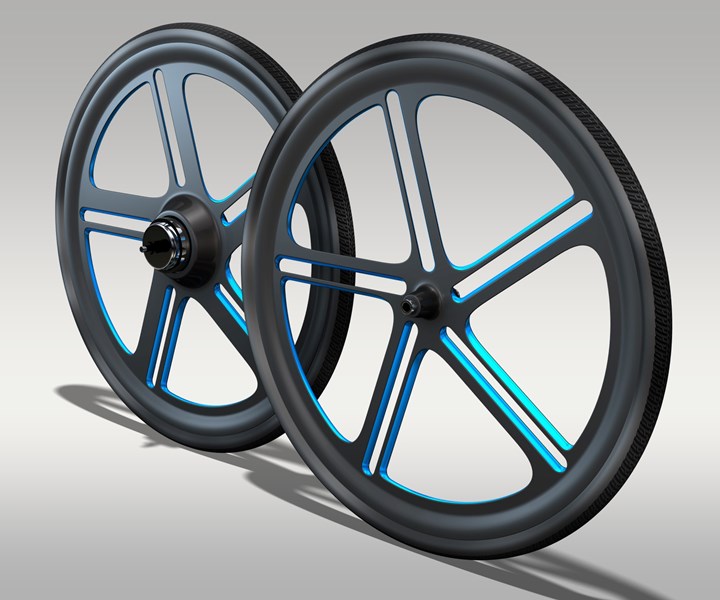

Arevo (Milpitas, Calif., U.S.) announced on Aug. 27 that it will display the world’s first 3D-printed carbon fiber unibody production bike frame at Eurobike 2019 next week in Friedrichshafen, Germany. Also on display will be Arevo’s 3D-printed thermoplastic rim, designed by Eurobike Gold Award-winning industrial designer Bill Stephens of StudioWest. The frame and rim will be displayed at the stand of Arevo’s manufacturing partner Oechsler AG (Ansbach, Germany).

The bicycle components were produced via the company’s “Arevo DNA” technology, which is an additive manufacturing (AM) process featuring patented software algorithms that are said to enable generative design techniques, free-motion robotics for “True 3D” construction, and direct energy deposition for virtually void-free construction optimized for anisotropic composite materials.

The company says its Arevo DNA AM process takes the design and final manufacture of a bike frame from 18 months to a few days, and with significantly reduced production costs. Other benefits are said to include:

- the capability for serial, volume production of AM-made composite parts that are made with thermoplastic materials,

- a fully automated, “lights out” production method to replace manual processes,

- the ability for localized manufacturing or “on-shoring,” which creates greater independence for bike brands, and

- freedom of design for bike manufacturers, creating the possibility for fully-customized bikes made on an on-demand basis.

“Arevo DNA offers a new paradigm for product designers, it forever changes how we can design and build anything,” says Stephens. “This technology allows us to push design boundaries in a way that was impossible until now. Arevo is changing the paradigm to ‘Manufacturing for Design’.”

At Eurobike 2019, Stephens will give a presentation, titled “3D Printing Carbon Fiber Frames for Production,” at 11 a.m. on Thursday, Sept. 5.

Arevo also is offering demonstration rides on an e-bike featuring this innovative frame and material, and will announce a new e-bike frame design and customer, who will display the new e-bike in the Eurobike exhibition hall.

Related Content

-

KraussMaffei and partners develop sustainable, safe and stylish children’s bike

The Lion Bike is a German-made, injection molded bicycle with 40% recycled carbon fibers with zero scrap and enabling 67% lower CO2 emissions during production.

-

Repurposing wind blades as functional community art pieces

Ohio-based Canvus Inc. upcycles fiberglass wind blades, car tires and post-consumer plastics to create outdoor furniture that amplifies sustainability messages in community spaces.

-

Toray rCF from Boeing 787 is incorporated into ultra-light laptops

Torayca-based aerospace components have successfully been repurposed into the Lenovo ThinkPad X1 Carbon Gen 12, highlighting the ongoing application of recycled composites.

.jpg;width=70;height=70;mode=crop)