Ariane 6 heavy-lift rocket makes inaugural launch

Carbon fiber launch vehicle powered into space in early July, demonstrating its ability to launch missions from low-Earth orbit and into deep space.

A joint press release from the Ariane 6 Task Force — ESA, CNES, ArianeGroup and Arianespace — released on July 9th announced the inaugural flight of Ariane 6, a new heavy-lift rocket, from Europe’s Spaceport in French Guiana. It is the latest in Europe’s Ariane rocket series, featuring a modular and versatile design that can launch missions from low-Earth orbit and farther out into deep space. Speaking on its success, ESA’s director general Josef Aschbacher notes, “A completely new rocket is not launched often, and success is far from guaranteed.”

Ariane 6 was built by prime contractor and design authority ArianeGroup (Paris, France). At more than 60 meters tall, Ariane 6 weighs almost 900 tonnes when launched with a full payload. It comprises three stages — two or four boosters, and a main and upper stage. The rocket’s fairing (nose cone) is 5.4 meters in diameter and made of carbon fiber developed by Beyond Gravity (Zürich, Switzerland). A 2022 report says that Airbus (Toulouse, France) also provided four primary lightweight carbon fibers structures for the next 14 vehicle launchers, and FACC (Ried im Innkreis, Austria) was contracted in 2021 to to develop and manufacture the Astris kick stage main structure for the new launch vehicle family.

At 21:06 BST (4:06 CEST), one hour after liftoff, the first set of satellites on board Ariane 6 were released from the upper stage and placed into an orbit 600 kilometers above Earth. Satellites and experiments from various space agencies, companies, research institutes, universities and young professionals were included on this inaugural flight.

The inaugural flight, designated VA262, was a demonstration flight whose aim was to show the capabilities and prowess of Ariane 6 in escaping Earth’s gravity and operating in space. In addition to the rocket, the liftoff demonstrated the functioning of the launch pad and operations on the ground at Europe’s Spaceport. The new custom-built launch zone was built by France’s space agency CNES and enables a faster turnover of Ariane launches.

“The next flight models [of Ariane 6] are already in production and the stages of the second model will be shipped to the Guiana Space Centre this autumn for the first commercial flight of Ariane 6,” says Martin Sion, CEO of ArianeGroup.

With the placement of satellites into orbit, Ariane 6 has demonstrated that it can successfully launch its payloads into space, but ground control has more in store for its inaugural flight. Ariane 6’s upper stage will prove again that it can restart its Vinci engine using its novel auxiliary propulsion unit. This restart capability will enable Ariane 6 to drop off multiple passengers into different orbits on future flights and de-orbit itself through Earth’s atmosphere at the end of its mission. On this flight, the Ariane 6 upper stage is set to release two reentry capsules as it enters Earth’s atmosphere for a clean disposal to burn up harmlessly, leaving no space debris in orbit.

The next Ariane 6 is planned for launch this year on its first commercial flight under Arianespace as operator and launch service provider. “The success of this first flight marks the start of Ariane 6’s operational career, giving Europe an autonomous access to space,” adds Stéphane Israël, CEO of Arianespace. “The new launcher’s order book is proof of the versatility of Ariane 6 and of its capacity to accomplish a wide range of missions into multiple orbits. We are eager to begin operating our new launcher.”

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

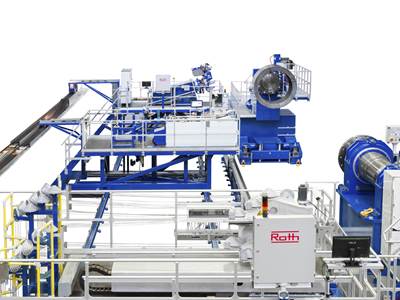

Roth filament winder to facilitate major Ariane 6 weight/cost cuts

One of the world’s largest filament winding systems will soon begin manufacturing components for the Ariane 6 space launch vehicle, which is expected to transport satellites into Earth orbit for the European Space Agency (ESA) as early as 2020.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More