Arkema, CNRS open France-based lab for UV-curable material exploration

Accelerated photopolymerization research to benefit adhesives, 3D printing, composites, electronics and coatings applications, among others.

Specialty materials company Arkema Inc. (Exton, Pa., U.S.) recently announced a partnership with the French National Center for Scientific Research (CNRS, Paris, France) and the Université de Haute-Alsace (Brunstatt-Didenheim) to inaugurate a new lab at the Mulhouse Institute of Materials Science (IS2M).

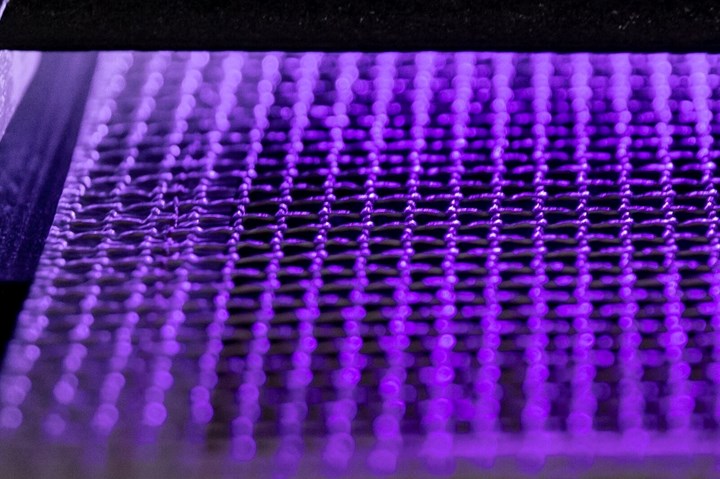

This lab will help accelerate research into photopolymerization, a future-oriented technology that improves energy savings and doesn’t require the use of solvents, and explore new and more sustainable UV-curable materials.

“Our goal is to design more sustainable specialty photopolymer materials for applications such as adhesives, 3D printing, composites, electronics and coatings, focusing on new market developments like new energies, clean mobility, home efficiency and lightweight materials,” Laurent Peyronneau, vice president at Arkema Coating Additives, says. “This initiative will support us to offer better sustainability throughout the value chain.”

Arkema has a long history of designing and marketing specialty materials for photopolymerization, through its flagship Sartomer product line, and custom formulations for 3D printing, through its N3xtDimension product line — for example, its partnership with Continuous Composites. UV-curable specialties are one of Arkema key low volatile organic compound (VOC) technologies, together with waterborne, high solid and powder.

For other related content, be sure to take a look at:

- “UV-curing grows composites market share”

- “Applying UV-curable powder coatings to composites”

- “Easy-to-use kits enable infield repair of composite structures”

Related Content

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.