ATL Composites contributes to concrete pillar remediation project

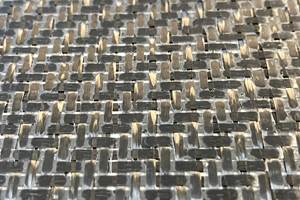

Six new support pillars incorporate Hexcel ZU300 UD carbon fiber and ATL’s Technirez R2517 epoxy resin with H2431 slow hardener that will protect against storm water issues.

Share

Read Next

Photo Credit: ATL Composites

It was reported on Nov. 18 that ATL Composites (Molendinar, Australia) was recently involved in a remediation project on a unit block in Coffs Harbour, Australia, with Binet Constructions (Quebec, Canada) and engineers. The project’s goal, to repair and reinforce the 40-year-old concrete pillars supporting the entire building, used high-performance carbon fiber composites to get the job done. A majority of them were suffering from concrete cancer, a result of exposure to the sea air and wear and tear over many decades.

Binet Constructions has a 50-year history in the Coffs region; however, using composites as the repair material was still relatively new to the company. “We hadn’t used carbon fiber on construction projects before, but it was specified by the engineer and we believed it would be perfect for the job,” says Murray Binet, the son of founder, Greg Binet. The Binets had previously worked with ATL epoxies, E- fiberglass reinforcements and DuFLEX composite panels in the construction of an 11-meter Schionning catamaran.

Binet Constructions first sent the specs for the resin and carbon to ATL’s Anthony Basilone, who suggested ZU300, a high-performance unidirectional (UD) carbon fiber material manufactured by Hexcel Corp. (Stamford, Conn., U.S.) and ATL’s Technirez R2517 epoxy resin with H2431 slow hardener to laminate the reinforcement.

“We see much more potential applications for this product and technique, specifically the remediation of bridges, buildings and other construction projects.”

Techniglue R60 structural adhesive thickened with WEST SYSTEM 413 Microfibre Blend was also used as a surface filler on the patched concrete, to provide a flat surface for the carbon to bond to. Synthetic peel-ply was used to wrap the carbon reinforcement in order to provide a textured surface that would reduce the amount of sanding required prior to the application of the final finish.

The apartment block comprised 16 units in a four-story building. There were six columns in the car park in the basement of the building that required repairs. Each pillar supported 60 tonnes.

According to Murray Binet, the most challenging part of the work was “creating the new support structure in a 40-year-old building. The building had long-term storm water issues as well.”

Despite this, ATL’s carbon fiber reinforcements and Technirez structural epoxy were said to be ideal for the job. “They’re lightweight, easy to work with, watertight when glued on and strong,” Binet adds. “In fact, the combination of the ATL products exceeded the engineer’s specifications.”

ATL’s Anthony Basilone explains, “The engineers decided on a specification where the original pylons were to be ground back to good material, patched with a mortar mix, wrapped in epoxy/carbon and then an additional pylon added to increase the overall strength. The carbon wrapping was used to ensure the old pylon would last as long as the new ones.”

The benefit of this procedure, rather than removing the pillars and replacing them was that residents didn’t have to move out while the building underwent major construction work.

“Removing the pylons, reinforcing the foundations with lintels would have been a huge undertaking, resulting in relocation of residents, added expense and a loss of rental income for owners. It was certainly more cost-effective, quicker and less hassle all round,” says Murray.

“The carbon fiber product from ATL was excellent,” he adds. “We see much more potential applications for this product and technique, specifically the remediation of bridges, buildings and other construction projects.”

Related Content

Pittsburgh engineers receive $259K DARPA award for mussel-inspired underwater adhesion

The proposed META GLUE takes inspiration from hydrogels, liquid crystal elastomers and mussels’ natural bioadhesives to develop highly architected synthetic systems.

Read MoreHenkel receives Airbus qualification for European aerospace manufacturing facility

The adhesive company’s Montornès, Spain, plant has been approved as a standard and raw materials supplier for various Airbus platforms, adding to its work in lightweighting, fuel efficiency and automation.

Read MorePontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.

Read MoreHeat-activated foaming core rapidly achieves net-shape 3D parts

CAMX 2024: L&L Products exhibits its InsituCore foaming core structural technology, which can be used to create foam core composites minus machining or presses, as well as the Phaster A K-700, a rapid-cure adhesive.

Read MoreRead Next

WEAV3D composite material approved for infrastructure reinforcement applications

Durable, strong and resistant to corrosion, the thermoplastic-based lattice material is suitable for use in Oldcastle Infrastructure’s polymer concrete and sheet molding compound (SMC) composite products.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More