Bcomp closes $40 million Series C funding to accelerate flax fiber adoption

New funding round supports enhanced production capacity, commercial automotive opportunities and new market support for flax fiber-based composite solutions.

Bcomp co-founders Christian Fischer, CEO (left) and Julien Rion, CTO (right). Source (All Images) | Bcomp

Bcomp Ltd. (Fribourg, Switzerland) has completed a $40 million Series C investment funding round. The round, led by Swiss institutional investor EGS Beteiligungen AG (EGSB), will help Bcomp scale production capacity of its flax fiber-based composite materials to convert an advanced pipeline of commercial opportunities in industrial automotive and support its entry into new markets in Asia and North America.

New investors include Verve Ventures, Zürcher Kantonalbank and RKKVC. The funding round also saw a group of Series A and Series B participants deepen their investment in Bcomp, including Generali and Airbus Ventures, in addition to strategic investment funds associated with high-profile OEMs such as BMW i Ventures, Porsche Ventures and Volvo Cars Tech Fund.

“The success of this funding round speaks to the belief of investors in our high-performance decarbonization solutions,” says Bcomp chairman Christian Jaag. “This investment will expand our existing markets as well as propel our growth into new sectors.”

Already seeing industrial-scale applications of its products at Volvo and Polestar, Bcomp will also build on its position in the biocomposite market by introducing lightweighting and sustainable solutions for additional verticals that include rail, buses, aviation, aerospace and consumer goods.

Many of the add-on parts on Porsche’s visionary fully electric Mission R concept car are made using Bcomp’s natural fiber-reinforced plastic, including front splitter, the doors, the side skirts and diffuser.

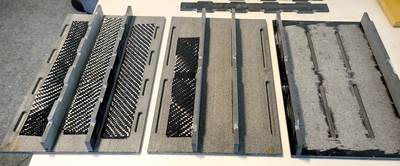

Originally developed to lighten and reinforce backcountry skis, Bcomp’s bio-based composites have been adapted and field-tested in motorsports to deliver performance benefits and positive sustainable impacts. OEMs associated with investors like BMW i Ventures, Porsche Ventures and Volvo Cars Tech Fund are already using powerRibs and ampliTex. For example, ampliTex fabric is being applied at volume for visible interior components in the new electric Volvo EX30, while BMW is using both products in the design of performance interior and exterior parts for its BMW M4 GT4.

The company’s materials contribute to decarbonization by enabling — for automotive interiors — a reduction in plastic content by up to 70% and total weight savings of up to 50% compared with traditional materials and techniques. The use of these natural, high-performance materials can also reduce the quantity of CO2 emitted from cradle to gate by up to 60%, Bcomp contends, and parts can be recycled and repurposed to serve a second life in another set of components. With certifications including IATF 16949 and ISO 9001, the thermoplastic product range is also a drop-in solution that can

be seamlessly integrated into volume production processes.

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Scale Advanced Composites natural fibers target cycling industry

Bio|Power and Cor|Power composite reinforcements aim to reduce materials costs and greenhouse emissions while enhancing performance.

Read MoreNovel DITF composite material enables CO2-negative construction

Three materials — bio-based carbon fibers, natural stone and biochar — act as an alternative to reinforced concrete in a house wall demonstrator in the DACCUS-Pre project.

Read MoreJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read More

.jpg;maxWidth=300;quality=90)