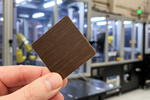

Scale Advanced Composites natural fibers target cycling industry

Bio|Power and Cor|Power composite reinforcements aim to reduce materials costs and greenhouse emissions while enhancing performance.

Share

Read Next

Source | Scale Advanced Biocomposites

Scale Advanced Biocomposites (Grenoble, Isere, France) a textile manufacturer developing bio-based composite reinforcements, has unveiled its Bio|Power and Cor|Power product lines. The materials are designed to replace or enhance carbon fiber. By doubling down on the inherent benefits of natural fibers and bio-based materials, including low density and optimized damping characteristics, Scale hopes to enables composites manufacturers to move to sustainable materials for new levels of performance while reducing materials costs:

- Bio|Power yarns are a blend of multiple natural fibers to create a range of performance and cost characteristics. The first Bio|Power EX blend is expected to reduce fiber costs by up to 40% and greenhouse emissions up to 95% versus carbon fiber.

- Cor|Power is a damping filament which helps reduce the effects of vibration and harshness in carbon fiber by up to 30% when incorporated at 10% by weight.

Scale says that it is initially working with bicycle manufacturers to address industry challenges, including the trade-off between stiffness and comfort — which has been exacerbated by the focus on aerodynamics in modern bicycle design — as well as improving product margins, which particularly benefits manufacturers producing in Europe and North America.

Scale contends that its materials can provide significant benefits to manufacturers and cyclists alike, improving stiffness-to-weight performance, impact resistance and vibration damping for a smoother ride.

“The cycling market is a perfect test bed for us. Cyclists are sophisticated customers with an unwavering demand for performance,” says Lance Johnson, CEO of Scale. “The damping properties of our materials, coupled with the ability to enhance stiffness without adding weight by using Bio|Power in narrower tube profiles, improve product performance while reducing environmental impact.”

“We’re working with Scale as part of a long-term project to improve sustainability in bikes,” says Martin Meir, managing director of Reap Design (Staffs, U.K.). The company has combined Bio|Power and Cor|Power in early testing to reduce carbon fiber content by 20%, increasing frame stiffness by more than 5% without weight penalties. “Additionally, we expect better compliance in the frame and lower transmission of road vibration which will reduce rider fatigue,” Meir adds.

In another collaboration with 3T Cycling (Turin, Italy), Bio | Power has been tested in the company’s 3T RaceMax Italia layup, enhancing stiffness-to-weight of the bottom bracket by 5%. “We’re looking at how Bio|Power can reduce the quantity of material we use while preserving our current stiffness-to-weight, to have an even greater impact on our greenhouse emissions,” Enrique Romero Pineda, managing engineer, 3T Cycling, says.

Related Content

-

Flax composites enter serial automotive production via Volvo EX30

The small SUV, which focuses on sustainability and is designed to have the lowest carbon footprint of any model in Volvo Cars’ history, incorporates Bcomp ampliTex fibers in its dashboard and door trim.

-

Evolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

-

Melker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.