Carbon fiber components featured in Polestar 1

Carbon fiber components have been used extensively in the car’s structure, including the bonnet, boot lid, side panels, doors and the entire roof structure.

Polestar (Gothenburg, Sweden) on June 18 offered a peek at the construction of the Polestar 1, low-volume electric performance hybrid GT. The car makes extensive use of Carbon Fiber Reinforced Polymer (CFRP). Producing an overall weight saving of 230 kg, most of the main body parts are constructed from the light-weight material.

The Polestar 1’s carbon fiber body represents the first time that the Volvo Car Group (Gothenburg, Sweden) has explored carbon fiber construction. The Polestar Production Centre, which is currently under construction and due to begin full-scale production in mid-2019, is being specifically tooled to deal with the intricate nature of carbon fiber construction.

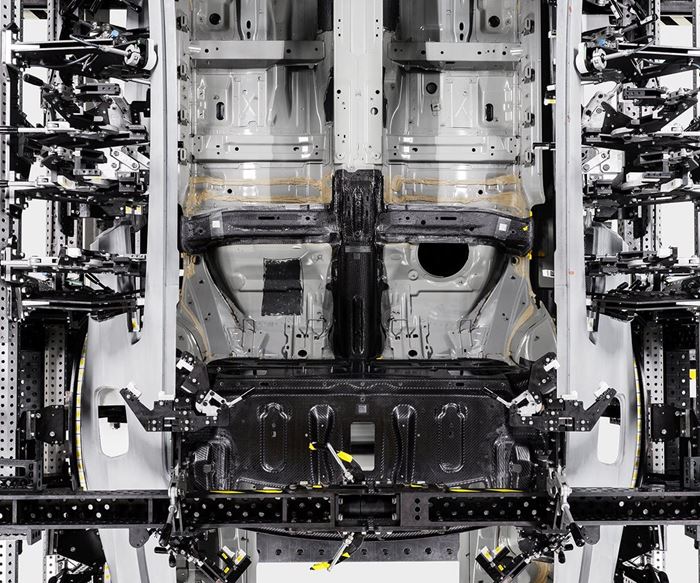

According to Polestar, carbon fiber components have been used extensively in the car’s structure, including the bonnet, boot lid, side panels, doors and the entire roof structure. “The ‘dragonfly’ is also made from CFRP,” says Christian Samson, head of product creation at Polestar.

The dragonfly-shaped component is said to play an instrumental role in creating the Polestar 1’s reactive dynamics – it reportedly improves torsional stiffness at one of the critical points in the body structure, between the middle of the floor and rear construction.

“When you combine this strengthened framework with the super-strong body and roof structure, you get a stiff and communicative chassis which translates driver input into superb driving characteristics,” continues Christian Samson.

Carbon fiber also contributes to the Polestar 1’s design. The carbon fiber roof structure is not only thinner and stronger than a steel equivalent but also allows for a much lower roof line.

Thomas Ingenlath, CEO at Polestar, says, “Carbon fiber is crucial in meeting our design, engineering and performance goals with the Polestar 1. The result is a beautiful, technological package that remains faithful to the original design with its elegant and low silhouette.”

Related Content

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.