CDI Energy Products high-performance thermoplastic excels in highly corrosive application

Achieving API 610 recognition, the proprietary thermoplastic polymer sustains differential pressures of more than 200 psi and holds a temperature profile of -20ºF to 105ºF.

Non-metallic wear components for centrifugal pumps using dures thermoplastic materials Photo Credit: CDI Energy Products

On May 25 CDI Energy Products (Houston, Texas, U.S.), a high-performance polymer components company, announced that its latest proprietary thermoplastic polymer composite material, dures 200, achieved API 610 recognition — the standard for centrifugal pumps for petroleum, petrochemical and natural gas industries — and outperformed service life expectations under extremely corrosive sulfuric acid conditions.

According to the company, the thermoplastic was the foundation for critical components developed for an API 610 vertical single casing diffuser pump (VS1) for a high-production sulfuric acid plant. CDI’s material scientists and engineers collaborated with the pump OEM to custom design suction bell eye case rings, bowl eye case rings and bowl bushings which could sustain differential pressures of more than 200 psi, coupled with an extreme temperature profile of -20ºF to 105ºF (-28.8ºC to 40.55ºC).

The pump OEM, a global industry leader in centrifugal, positive displacement and specialty pumps required a material with higher thermal stability and higher creep resistance than polytetrafluoroethylene (PTFE). CDI’s dures 200 was developed to support service applications with aggressive acids and bases, aromatics and amines. The pump OEM has indicated that the custom components are still in active use by the end-user and have far exceeded the vertical pump’s typical service maintenance schedule with a significant reduction to costly downtime.

According to Dr. Tim Bremner, materials technology director at CDI, “In the past decade, thermoplastic-based materials development in the energy and chemical process sectors has been dominated by the push for operation at higher temperatures and higher pressures. The added challenge of achieving customers’ performance targets in very high or very low pH fluid handling, as encountered in sulphuric acid production or caustic amine gas treaters, introduces another challenge to material design due to the limitations these corrosive environments place on our choice of fillers and reinforcements. We are more than enthusiastic about the performance of dures 200 in pump applications where the combined temperature, pressure and corrosive fluids would cause premature failure in lower-performing materials.”

Currently, says the company, dures 200 is delivering similar results for custom-designed components in single-stage overhung pumps and horizontally split multistage pumps with lean amines under pressures that surpass 200 psi. CDI notes that pump operators using the thermoplastic materials can operate their equipment with tighter clearances, decreasing vibration and downtime while improving and boosting efficiency. CDI’s materials are also said to improve reliability and reduce maintenance costs by reducing the risk of pump failures due to touch-off or dry running conditions during start-up. In the dures family of materials, A451 and XPC2 are also recognized by API and meet the requirements of API 610 for stationary wear or rotating parts applications.

“API pumps are manufactured to meet certain industrial requirements including specifications that directly affect performance and safety. Designing components for those extreme duty pumps requires extensive technical knowledge of both the equipment and the environments for end use,” says Gary Gibson, P.E., CDI’s senior sales engineer for API 610 Pump Components.

Every five years, the API Committee convenes to review API standards and seek comments from its members which includes oil and gas industry leaders and distinguished industry institutes. “When the API 610 Twelfth Edition was released earlier this year, we were thrilled to learn that dures 200 was now recognized in the non-metallic wear part materials selection,” Gibson says.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRead Next

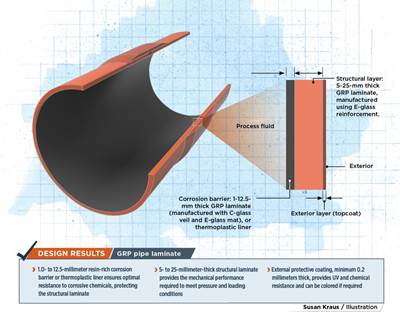

Corrosion-resistant composite piping over the long haul

Three decades of lessons learned using corrosion-resistant glass fiber-reinforced composites in piping at SABIC’s Netherlands chlorine production plant.

Read MoreComposites extend service of oil and gas pipelines

Corrosion-resistant aramid fiber/thermoplastic liner gives new life to deteriorating steel subsea pipelines.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)