The safe and uninterrupted operation of its chlorine production plant in Bergen op Zoom, Netherlands, is the main priority for chemicals manufacturer SABIC (Riyadh, Saudi Arabia). The plant began operations in 1987 and processes chlorine gas, strong acids and alkalis at elevated temperatures, which are highly corrosive environments where steel pipes could fail in only a matter of months. To ensure maximum corrosion resistance and reliability, SABIC selected glass fiber-reinforced plastic (GRP) for critical pipes and equipment from the start, and materials and manufacturing improvements implemented over the years have increased the design life of the composite components to 20 years, so that they need to be replaced less frequently (scroll down for a side story on chlorine production).

“We want to make sure that chemicals like chlorine, hydrochloric acid and hydrogen remain inside an enclosed environment and are well contained,” states Thana Kammeijer, manager, chemical operations, for the SABIC chlorine unit. “At the same time, we do not want an equipment failure to interrupt the continuous operation of the chlorine unit, as this may affect the downstream processes on this site. Therefore, we closely follow the condition of all piping and equipment and take the right actions for preventive maintenance.”

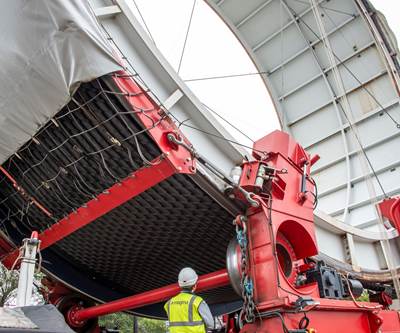

The 40-50 kilometers of GRP piping installed at SABIC’s Bergen op Zoom, Netherlands, plant contain highly corrosive chemicals, including chlorine gas, sodium hydroxide and hydrochloric acid. Source | SABIC

GRP pipes, vessels and assemblies manufactured by Versteden BV (Bergen op Zoom, Netherlands) using resins supplied by DSM Composite Resins (now part of AOC, Collierville, Tenn., U.S., and Schaffhausen, Switzerland), have been employed from the beginning. A total of 40-50 kilometers of composite piping, consisting of approximately 3,600 pipe segments of various diameters, is installed in the plant.

The reliability and durability offered by composite materials in this corrosive environment were decisive factors in their selection for this project.

“Plant designers are conservative, and their first thought regarding material of choice for equipment and piping is steel,” explains Thomas Wegman, marketing manager at AOC. “SABIC has always prioritized process safety and obviously wants processes to run without interruptions. Corrosion resistance together with mechanical strength and durability were the main reasons for selecting composites over alternative materials like steel, in combination with their cost competitiveness.”

The right choice

Over the years, Versteden has optimized the design and manufacture of connections such as tees, helping to extend the design life of the chlorine plant’s piping. Source | AOC

“Brine, hydrochloric acid, sulfuric acid and sodium hydroxide are obviously highly corrosive materials,” comments Paul Peterse, mechanical integrity engineer at SABIC. “In some applications we chose to use pure composite piping, while for other applications (including wet chlorine gas streams) we selected composite pipes with thermoplastic liners like PVC and PTFE.”

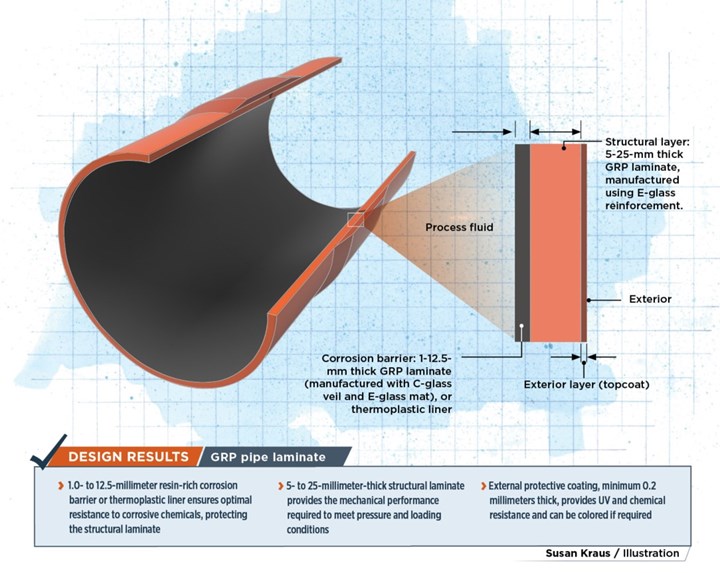

The composite components are produced using filament winding or hand layup, depending on the design, size and complexity of the part. A typical pipe structure consists of an interior corrosion barrier layer, 1.0-12.5 millimeters thick, for optimal chemical resistance; a 5-25-millimeter structural layer to provide mechanical strength; and an external coating about 0.5 millimeter thick to provide protection from the plant environment. The inner liner provides chemical resistance and acts as a diffusion barrier. This resin-rich layer is manufactured with C-glass veil and E-glass mat and has a standard nominal thickness between 1.0 and 12.5 millimeters and a maximum glass/resin ratio of 30% (based on weight). This corrosion barrier is sometimes replaced by a thermoplastic liner to prove greater resistance to specific materials. Liner materials can include polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE), polytetrafluoroethylene (PTFE), polyvinylidene difluoride (PVDF) and ethylene chlorotrifluoroethylene (ECTFE).

The structural layer employs E-glass reinforcement (rovings, woven roving and/or chopped strand mat). Wall thicknesses depend on the pipe diameter and pressure class and are typically between 5 and 25 millimeters. Depending on the manufacturing process (hand layup or filament winding) the structural wall has a glass/resin ratio between 50% and 70% (based on weight). The UV-resistant outer layer consists of low weight synthetic veil, is relatively rich in resin, and has a minimum thickness of 0.2 mm. On request, the external layer can be supplied in any RAL color.

In many corrosion applications, the resin chosen for the structural laminate is frequently the same as that in the corrosion barrier, since chemicals may diffuse through the barrier layer. But in critical applications such as pipes used to transport chlorine, a resin with greater corrosion resistance is required for the barrier layer.

Filament winding at Versteden’s production facility in Bergen op Zoom. Source | AOC

When choosing a resin for a chemical environment, a number of complex factors need to be taken into account, including: the chemical’s concentration and pH values; service and maximum temperatures; pressure, static and cyclic loading; reinforcement and layup used; and manufacturing technique. Versteden selected AOC’s Atlac 580 bisphenol A vinyl ester urethane resin, Atlac E-Nova FW 2045, a modified epoxy bisphenol A urethane vinyl ester, and Atlac 382 bisphenol A unsaturated polyester resin for the SABIC plant. AOC has built up an extensive corrosion resistance database detailing how its resins perform in contact with different corrosive media, and Atlac resins have been used in corrosion applications for more than 40 years. This experience is important for manufacturers and end users.

“The Atlac resins have a long track record of consistent performance in pipes and assemblies used in chemical plants,” says Erwin Simons, technical director at Versteden. “The resin quality gives us a huge predictability and consistency of our production.”

Achieving a 20-year design life

For SABIC, defects resulting from part corrosion must be kept to a minimum. Strong chemicals can attack the surface of the composite components, resulting in a visible discoloration which has limited effect on mechanical performance or chemical resistance, or more importantly, a reduction of the thickness of the corrosion barrier layer.

“We inspect pipes and pipe connections continuously in order to understand their condition and minimize the risk of potential leaks,” Peterse reports. “We mostly use visual inspection methods, and to some extent X-ray and ultrasound techniques. This gives great insight into the condition of the parts and confirms composites are very reliable construction materials for contact with corrosive chemicals at elevated temperatures.”

SABIC also conducts a detailed inspection of composite pipes and vessels every four years as part of a scheduled site-wide turnaround. The results of this inspection determine if the composite components can remain in operation for another four-year cycle or whether they need to be replaced. Over the 32 years of the plant’s operation, SABIC, Versteden and AOC have introduced design and manufacturing improvements that have increased the time intervals between replacement.

To ensure the optimal performance of composite components in chemical environments the correct combination of design, materials and manufacturing process is essential. Source | AOC

“In the early years, SABIC was cautious using composites, and replaced pipes and tanks in critical areas every eight years,” Simons states. “Since then, we have worked with SABIC and learned together how these materials perform over a longer period of time. As a result, we were able to extend the lifetime of composite components and assemblies through optimizing part design, fine-tuning part production processes and improving overall quality consistency.”

In order to achieve the most accurate prediction of final part performance Versteden has defined in detail the individual manufacturing process steps for pipes and assemblies. During manufacture, these steps are followed carefully so that the assembly’s functional and mechanical performance is fully in line with the original design. Based on feedback from SABIC and insights gained on material performance over the years, Versteden has also optimized pipe connections such as tees by ensuring that alignment and over-lamination are performed cautiously and consistently. Joints have to be made in the correct way to ensure continuity of the corrosion barrier layer and avoid any imperfections which could result in chemical leaks.

“During part production at Versteden all elements of the process are monitored and recorded, so we can trace any anomalies,” Erwin reports. “Our employees in production are well trained and certified by external parties in the processing of composite materials.”

The design life of a typical part in contact with corrosive chemicals is now 20 years as a result of improved resins and production techniques, whereas previously it was 15 years.

“Keeping my plant in the right condition and knowing that the chemicals stay where they should be, are my highest priorities,” Thana Kammeijer adds. “I am very happy that through all these years composite solutions have proven that they are capable of performing under such tough environmental conditions. And that we can also rely on knowledgeable partners like Versteden and AOC to make these materials work for us.”

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Filament wound utility poles offer design flexibility

In Turkey, a utility pole manufacturer combines filament winding, automation, glass and carbon fiber composites to expand its product line.

Read MoreThermoplastic composite pipe on the rise in the deep sea

Demonstrators, pilot programs and qualification efforts are paying off as thermoplastic composite pipe (TCP) makers take orders for deep-sea oil and gas applications.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More