Clean Sky 2 project announces new project updates

Update on 11th call for proposals and Clean Sky 2 projects, plus composites topics of interest in upcoming AEC2020 conference.

The Clean Sky 2 project, the EU Horizon 2020 program-funded research program developing innovative, cutting-edge technology aimed at reducing CO2, gas emissions and noise levels produced by aircraft, has released several recent announcements:

Clean Sky 2’s 11th Call for Proposals launched – deadline 28 April

Clean Sky 2 has issued its 11th Call for Proposals for innovations in sustainable aviation representing €45 million in funding for 35 topics, including 4 thematic topics. Questions may be submitted until March 13, 2020 (17:00 Brussels time) and the deadline to apply is April 28, 2020 (17:00 Brussels time). Updates are available on the Clean Sky 2 website.

For organizations interested in applying that want to learn more, registration is open for Clean Sky 2 Info Days, where experts will be on hand to give an insight into the Topics and discuss practical, legal, administrative and financial aspects:

- Toulouse (France) on 3 February – register here

- Rzeszów (Poland) on 13 February – register here

Save the date: Aerospace Europe Conference 2020

Clean Sky is pleased to take part in the very first edition of the Aerospace Europe Conference (AEC2020, Feb. 25-28, 2020) to be held in Bordeaux, France and organized by 3AF (Association Aéronautique et Astronautique de France) and CEAS (Council of European Aerospace Societies) with the support of Clean Sky, SESAR (Single European Sky ATM Research project) and ESA (European Space Agency).

AEC2020 will provide an exceptional opportunity to exchange knowledge and results of current studies and to discuss directions for future research in the fields of aeronautics and space. Clean Sky will be present with an exhibition stand and speakers in the conference program. Sessions that should be of interest to the composites industry include:

- 008 - Passenger aircraft composite centre wing box structure optimization — M. KOWALSKI, Warsaw University Of Technology, PL

- 127 - Hybrid Sheet Moulding Compound With Carbon Prepregs — J. SILVA, Inegi, PT

- 136 - Automated Fiber Placement based manufacturing of carbon fiber reinforced sandwich shell parts — T. ZENKER, Fraunhofer, DE

- 139 - Impact Resistant and Low-Weight Composite Solution for Aircraft Fuselage — R. RICARDO JORGE BRAGA ROCHA, Inegi,PT

- 315 - Automated Joining and Assembly of Thermoplastic Fuselage Structures for the Aircraft Factory of Tomorrow — B. DIEHL, Fraunhofer IFAM, DE

- 408 - Generating durable hybrid Ti/CFRP adhesive joints for aerospace structures by laser pretreatment — U. LOMMATZSCH, Fraunhofer IFAM, DE

- 424 - Clean Sky SFWA BLADE and Saab‘s integrated composite upper cover — K. KARLSSON, SAAB ab, SE

- 445 - Experimental and numerical study of the composite wing structure embedding solar cells — Q. ROUXEL, Gem – Institut De Recherche En Génie Civil Et Mécanique, FR

- 481 - Development of a Multifunctional Fuselage Demonstrator — V. SEBASTIAAN, Fokker, NL

- 503 - Optimizing in-situ consolidation of xenon flashlamp based automated fiber placement — D. DEDEN, DLR (German Aerosapce Center), DE

- 564 - Sensing technologies in the frame of Structure Health Monitoring — M.-A. DE SMET, Airbus Commercial, FR

- 588 - Genetic optimization of stacking sequences for laminated composite structures with ply drops — A.F. CORTESI, Scalian, FR

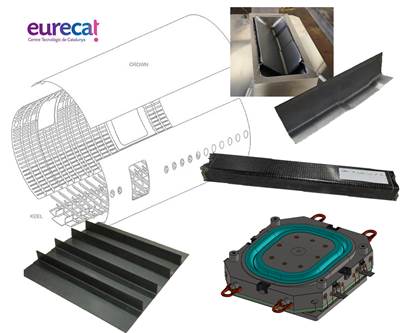

- 606 - Design and manufacturing maturation of a Thermoplastic Composite Keel-beam — L. ANGEL, Eurecat Tech Center, ES

- 734 - Optical fibre Bragg grating sensors for BVID detection on composite sub-components — S. GOOSSENS, Vrije Universiteit Brussel, BE

- 746 - Structural Health Monitoring Cluster for Composite Airframe — Z. Sharif Khodaei, Imperial College, GB

- 747 - Innovative manufacturing and numerical modelling of thermoplastic and thermoset composite structures for SHM aerospace application — M. Mora-Mendias, FIDAMC, ES

These and other announcements can be found in the latest Clean Sky 2 newsletter available online and also on the Clean Sky 2 website. The Clean Sky 2 program also publishes the Skyline magazine and has a video playlist on YouTube.

Related Content

SGL Carbon carbon fiber enables German road bridge milestone

A 64-meter road bridge installed with carbon fiber reinforcement is said to feature a first in modern European bridge construction, in addition to reducing construction costs and CO2 emissions.

Read MoreSwedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRead Next

Clean Sky 2’s PASSARO project targets one-shot OOA composite cockpit

Synergies with MOSHO project for NDT, repair and also developing cobots for 70% cut in cycle time.

Read MoreThermoplastic composite demonstrators — EU roadmap for future airframes

There is a TPC development roadmap in Europe, supported by Airbus and a variety of aerospace consortia, and involving almost every major aerostructures supplier in Europe.

Read MoreAdvancing thermoplastic composites and RTM for Clean Sky 2 in Spain

EURECAT leads projects for TPC keel beam, window frames and thermoset RTM fuselage frames with TPC shear ties for next-gen aircraft.

Read More

.jpg;maxWidth=300;quality=90)