CNT-enhanced carbon fiber strengthens mountain bike team's race wheels

NAWA’s vertically aligned carbon nanotube technology enhances shock resistance, increases strength for Santa Cruz team’s mountain bike wheels.

Nanomaterial technology specialist NAWA (Dayton, Ohio, U.S.) announced on July 1 that its nanotechnology-enhanced carbon fiber materials will be featured in composite racing wheels by the Santa Cruz Syndicate downhill mountain bike team. NAWA has been named an official Santa Cruz Syndicate partner in 2021, and this is the fourth competitive season that Santa Cruz has employed wheels using NAWA’s materials.

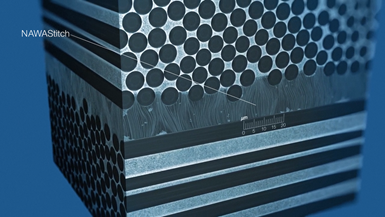

The competition-only Reserve rims feature NAWA’s materials concept, NAWAStitch, which employs carbon nanotube (CNT) technology to enable more resistance to strike damage and higher strength than conventional carbon fiber. According to NAWA, NAWAStitch has the potential to reduce the number of wheel failures experienced by the team over a competitive season by 80%.

NAWA’s technology works by integrating vertically-aligned carbon nanotubes (VACNT), which are manufactured by NAWA using a patented process, between the layers of a composite structure to add superior strength. For the Reserve wheels, the NAWAStitch material consists of a thin film containing trillions of VACNT, arranged perpendicular to the carbon fiber layers. Acting as “nano-velcro,” the tubes reinforce the interface between the layers, which is the weakest area of the part.

NAWASTICH also improves strike damage resistance by eliminating the probability that a crack will occur in the interface. In addition, in its own tests, NAWA has found that NAWAStitch-reinforced carbon fiber composites have shear strength increased by a factor of 100 and shock resistance by a factor of 10.

Nic McCrae, senior composites engineer at Santa Cruz, says, “In downhill racing, the wheels suffer hard, repeated impacts with rocks and roots. Failures occur when the tire bottoms out and the rim bead cracks. NAWAStitch has made the wheels much stronger, we believe by increasing the buckling resistance of the inner surface of the rims during these high compressions. What’s more, NAWAStitch does not affect the way wheels respond to the riders’ inputs — they behave completely consistently, which allows them to push harder and go faster. Through a combination of our own profile design, precise wheel-building and the introduction of NAWAStitch, our Reserve wheels are without doubt the strongest rims on the circuit.”

Pascal Boulanger, founder, chairman of the board and chief technology officer of NAWA Technologies, says, “NAWAStitch brings game-changing improvements in the core strength of composite materials and we are very proud to see its considerable performance benefits coming to the fore in the team’s Reserve race wheels. We look forward to working with Santa Cruz Syndicate and wish them every success in competition.”

Development of multifunctional ultra-strong composites, such as NAWAStitch, is led by NAWA’s NAWA America division, based in Dayton, Ohio and created in 2020 when NAWA acquired N12 Technologies. In addition to supporting the Santa Cruz Syndicate in the development of its competition-only Reserve wheels, NAWA America is finalizing development of NAWAStitch for use in volume industrial applications, and expects to ramp up to full production by next year. In the short term, first markets will be sporting equipment, consumer products and luxury goods, while longer-term prospects are in automotive and aerospace. Combined with its home facility in France, NAWA Technologies will offer a wider portfolio of solutions to its customers, combining lighter, stronger and smarter composites and energy storage.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

NAWA Technologies develops U.S. subsidiary to extend VACNT application scope

NAWA America’s immediate focus is to bring NAWAStitch to mass market, a thin film containing trillions of VACNT arranged perpendicular to the carbon fiber layers to reinforce the weakest part of a composite.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)