NAWA Technologies develops U.S. subsidiary to extend VACNT application scope

NAWA America’s immediate focus is to bring NAWAStitch to mass market, a thin film containing trillions of VACNT arranged perpendicular to the carbon fiber layers to reinforce the weakest part of a composite.

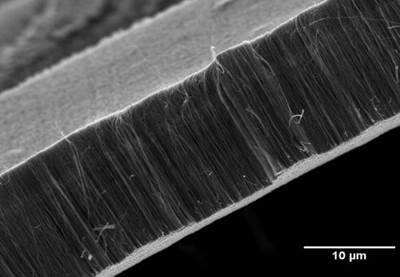

NAWAstich, a thin film containing trillions of VACNT arranged perpendicular o the carbon fiber layers. Photo credit: NAWA Technologies

NAWA Technologies (Aix-en-Provence, France), a company focused on next-generation energy storage systems, reported on Nov. 19 that it has further cemented its position as one of the world’s leading technology innovators, with the announcement of NAWA America, a new U.S.-based company focused on industrializing advanced composite materials.

Based in Dayton, Ohio, NAWA America was created through the acquisition of N12 Technologies (Somerville, Mass., U.S.) a company with a focus in vertically aligned carbon nanotubes (VACNT) for composite applications “see NanoStitch update: 60-inch wide sheet, industrial capacity, dramatic test results”). According to NAWA Technologies, bringing multifunctional ultra-strong composites that are aimed at sectors including automotive, aerospace, renewable energy, space, defense, sporting equipment and consumer and luxury goods is the cornerstone to NAWA America’s development.

“The creation of NAWA America is a very exciting and a natural strategic step. We have been aware of N12 Technologies’ exceptional work for many years; I am delighted the opportunity has arisen to acquire its activities, develop the technology further and bring it within our portfolio,” says Pascal Boulanger, founder of NAWA Technologies, chairman of the Board and CTO.

In the future, NAWA Technologies sees enormous potential in combining NAWAStitch and NAWAShell to create ultra-strong, multifunctional lightweight materials

NAWA America’s main objective will be to significantly widen the range of applications of multifunctional composites, engineering true, next-generation materials and substantially scaling manufacture. Its immediate focus will be on a bringing a new materials concept, NAWAStitch, to mass market. Comprising a thin film containing trillions of VACNT arranged perpendicular to the carbon fiber layers, NAWAStitch acts as ‘nano-velcro,’ reinforcing the weakest part of a composite: the interface between the layers. Eliminating the probability that a crack will occur in the interface, the concept also greatly improves strike damage resistance.

NAWA says that carbon fiber composites with NAWAStitch have their shear strength increased by a factor of 100 and shock resistance by a factor of 10. High-speed impact also results in 50% less interior damage versus a conventional carbon composite. Together, NAWA Technologies contends that this makes NAWAStitch the optimum way to reinforce the mechanical properties of carbon fiber composites.

In addition to continuing all of N12 Technologies’ activities in the VACNT field with existing and new customers, NAWA America has also established a research collaboration and license agreement with the University of Dayton Research Institute (UDRI), through the Multifunctional Structures and Materials Group run by Dr. Paul Kladitis, ranked number one in the U.S. in materials research. The company has also signed a field exclusive license agreement with the Massachusetts Institute of Technology (MIT), through Prof Brian Wardle’s (NECSTLAB) research group, well-known in the fields of composites and nanotubes.

According to the company, synergies already exist with NAWA Technologies. At its headquarters in France, it has independently created a multifunctional composite materials concept, NAWAShell. NAWAShell is an integrated structural hybrid battery, incorporating VACNT to give two complimentary characteristics: enhanced mechanical strength and electrical energy storage within the composite structure’s core. Potential use cases include a solar roof panel in a car that could generate energy stored within the roof, and provide a circular green solution, with almost no additional mass to the vehicle structure.

In the future, NAWA Technologies sees enormous potential in combining NAWAStitch and NAWAShell to create ultra-strong, multifunctional lightweight materials that can also store energy, whether in a vehicle, airplane, building or mobile device

“This move further cements NAWA Technologies as the leading specialist in VACNT, and the largest manufacturer of continuous industrial scaled VACNT,” says Boulanger. “Not only do we possess the rights and know-how for the two most efficient and complementary patented VACNT growth processes, strong academic support from both sides of the Atlantic, but also the expertise to bring two major applications of VACNT to a global market: ultra-strong composites and energy storage. We expect both sectors to grow exponentially over the coming decade. Innovations such as these will have a significant impact on the global search for a fully sustainable world, and also align with NAWA Technologies’ ethos to provide clean, sustainable energy solutions.”

According to Ulrik Grape, CEO of NAWA Technologies NAWA America’s objective is simple. “Combine the expertise that exists within the Dayton operation with that of NAWA Technologies, and harness the potential of our relationships and agreements with UDRI and MIT, in addition to our relationship already existing with CEA. This will allow us to finalize development of NAWAStitch and ramp-up to volume production in 2021. In the short term, our first markets will be sporting equipment, consumer products and luxury goods, while our longer-term focus is automotive and aerospace.”

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

The end of delamination?

A spin-off from MIT's NECSTlab, N12 Technologies Inc. launches NanoStitch, the world's first vertically aligned CNT product via a continuous industrial process, which bridges adjacent CFRP plies, boosting interlaminar shear and increasing fatigue life by 100%.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More