Composite-metal anti-roll bars make headway for lightweight automotive suspension systems

The LiMeCH project, led by the AMRC, Tinsley Bridge and Performance Engineered Solutions, developed filament-wound CFRP-metallic roll bar prototypes, with additional advances in joint bonding the hybrid materials.

The University of Sheffield AMRC worked with Tinsley Bridge and Performance Engineered Solutions to create a lighter alternative to the tubular steel bar currently used for suspension units. Photo Credit: AMRC

Two South Yorkshire, England, SMEs have joined forces with the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Rotherham, U.K.) to push the automotive sector further along the road to net-zero through the design, manufacture and testing of a high-performance composite stabilizer bar for trucks and trains that is claimed to be 30% lighter than those currently on the market.

The creation of a lighter alternative to the tubular steel bar currently used for automotive suspension units was initially established under the £400,000 Innovate UK-funded Lightweight Metal Composite Hybrid (LiMeCH) project. The AMRC Composite Centre worked with Sheffield-based engineer Tinsley Bridge (U.K.) and Performance Engineered Solutions (PES) in Rotherham (U.K.). Tinsley Bridge had previously worked with the AMRC to develop a metallic and carbon fiber-reinforced plastic (CFRP) hybrid composite roll bar, joined with an adhesive, on a project called Lightweight Composite Suspension Components (LiCoSuCo).

“Lightweighting is top of the agenda for our customers,” says Russell Crow, director of engineering at Tinsley Bridge. “That is even more so when they are looking at alternative propulsion systems, such as electric drive trains and alternative fuels, because every gram they can save offsets the additional mass they have to carry for the batteries or hydrogen fuel tank.”

Carbon fiber is not yet widely used for functional parts in the automotive sector, such as suspension systems, where the industry standard is a steel tube welded to metallic end fittings. However, composites could improve fuel efficiency, meet emissions regulations and are less affected by fatigue.

The results of this project have applications beyond the heavy industry.

The two-year project’s consortium aimed to create a suitable joint between a composite tube and a metallic end fitting that, together, form an anti-roll bar (ARB), a key part of a vehicle’s suspension unit. Crow notes that, as a minimum, the joint needed to be capable of transmitting the same loads as the equivalent part manufactured from steel spring.

“The key was finding a modular system,” he says. “This project was not about making a very expensive composite part, but about how we could bond together metallics and composites to create high configurability from a low number of stock parts.”

Craig Atkins, research engineer at the AMRC Composite Centre, says while the project made advances in the areas of volume composite manufacture, metallic arm production and bonding, it created other issues that the team had to develop solutions for. “We took outcomes from LiCoSuCo [the project with Tinsley Bridge] that didn’t succeed, in particular with the integrity of the bonded joint between the metallic and carbon fiber. The continued LiMeCH project builds upon the results of the previous project and continues its collaboration and research.”

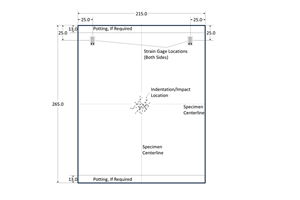

Performance Engineered Solutions (PES) used its expertise in composites and lightweight materials to design the ARBs, employing finite element analysis (FEA) to simulate the process prior to manufacture to determine whether the proposed designs could resist the loads an ARB is subjected to. “We needed to consider the ease of manufacture as well as the material selection, adhesive selection and how it would perform during non-destructive testing [NDT],” notes Stefan Dalberg, senior design engineer at PES.

The AMRC’s Composite Centre produced four anti-roll bar prototypes using its MF Tech filament winding system, which winds impregnated carbon fiber filaments onto a rotating mandrel to form a desired shape. PES penetratively inspected the inside of the bar using computed tomography (CT) scanning technology, then an in-house light scanning system to visually inspect the parts.

The prototypes were also subjected to rigorous testing, Crow adds. “Inspection of the composite system was key because these parts have different failure modes to the traditional steel that everyone in the industry knows, understands and is very comfortable with. We researched and developed a whole range of NDT techniques, both in-situ and on a test track, to understand if the part had been damaged, to what extent it had been compromised and whether it was suitable for continual use or not.”

Dalberg says that NDT means the consortium can now confidently state that they can bond metallics to composites in a manner that passes the fatigue requirements of industry. “We have done the NDT, environmental testing and impact testing; so, we have effectively looked at everything demanded of this bar under a vehicle and created the safety case,” he claims. “Now it is a matter of optimizing the design, because we can potentially make it even lighter, and continue to engineer out unit cost.”

According to AMRC’s Craig Atkins, the results of this project have applications beyond the heavy industry.

“The ARBs we prototyped are designed for trucks, trains and military vehicles, but it can be scaled down — there is no reason why this technology can’t be applied to electric vehicles [EVs] and smaller vans used by courier services,” he says. “As the automotive industry moves towards greater electrification and lighter-weight parts, there is ever greater focus on moving away from wholly metallic components. Finding a way to bond metallics to composites and reduce a component’s weight by almost a third is a significant step along the road to net zero.”

Related Content

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MorePhotothermal tomography for locating, quantifying defects in composites

Years of infrared testing development result in thermography technology that is no longer just qualitative, but can define defect size and depth, making additional UT scans obsolete.

Read MoreDamage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

Read MoreNotched testing of sandwich composites: The sandwich open-hole flexure test

A second new test method has been standardized by ASTM for determining notch sensitivity of sandwich composites.

Read MoreRead Next

U.K. consortium to develop hub for hydrogen storage prototyping in drive for net zero

A key aim of the HSPH platform is to set up further R&D projects for developing novel hydrogen storage prototypes, including Type IV vessels. The consortium is seeking partners for future demonstrator projects.

Read MoreComposite-metal joining, braided preforms enable next-generation aircraft design

Collins Aerospace invests in new joining, preforming and infusion techniques to target aircraft design needs for reduced weight and lower-cost manufacture.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)