Collins Aerospace’s Banbury, U.K., facility is known for filament-wound composite aircraft components like transmission shafts and fuel pipes. The company has recently invested in new technology for extending its capabilities toward more complex shapes and lower-cost manufacturing processes. Photo Credit, all images: Collins Aerospace

A variety of technologies will be needed to enable aircraft manufacturers to meet targets for increased manufacturing rates, increased efficiency and reduced emissions in next-generation aircraft design.

According to Collins Aerospace (Charlotte, N.C., U.S.), reducing aircraft weight through novel and effective use of composites, and implementing lower-cost manufacturing processes, will be critical to meeting these needs. Over the past several years, Collins Aerospace’s center of excellence in Banbury, U.K., has been developing new technologies to deliver novel lightweight solutions for components with complex shapes, with the goal of reducing the weight and increasing the affordability of future composite fuel pipes, shafts and other wingbox components.

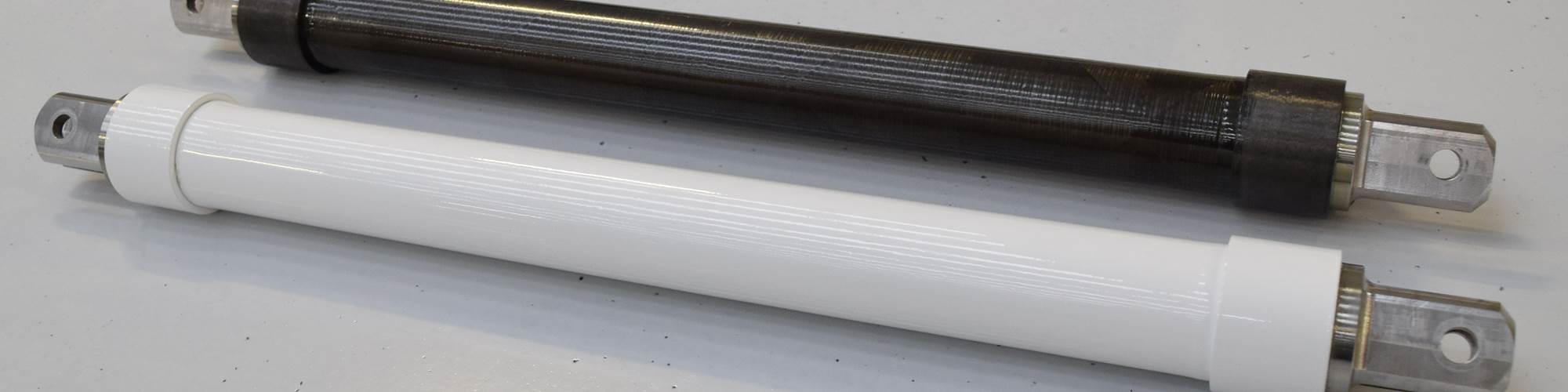

The Banbury facility was previously called the Crompton Technology Group (CTG) until a series of acquisitions that started in 2012. Since its beginnings, this facility has specialized in filament-wound composite parts. Over the past decade, it has focused primarily on aerospace products such as fuel pipes and transmission shafts, of which the company produces tens of thousands per year for various Airbus and Boeing aircraft, including the Airbus A350. The company has also manufactured transmission shafts for applications outside of aerospace, such as high-performance cars and trains.

Recently, Collins Aerospace has begun several research and development programs aimed at diversification into new markets and new technologies. One of the most developed is a composite-to-metal joint—called a tooth joint—for the transmission of axial loads via struts and tie rods.

More efficient, cost-effective composite-metal joining

“Straight, simple tubes are cost-effective, and structurally efficient because you can align the fiber to the direction of the load,” explains James Bernard, research and technology manager at Collins Aerospace. The most common way to connect a composite tube is through the use of a metal connector, where the composite tube is joined to the metal either mechanically or with the use of adhesives.

Collins Aerospace’s composite-metal joining technology aims to improve the efficiency and strength of mechanical joining for straight tube structures.

Typical mechanical joining techniques, however, can lead to inefficiencies in axial load transfer between the metal and composite components, Bernard says. Adhesives present challenges of their own: “One of the major problems with a bonded joint is that you have to be very careful how you prepare and clean the surface,” adds Russ Meddes, business development manager at Collins Aerospace. “If anything isn’t conducted correctly, you get a poorly bonded joint. Furthermore, a bonded joint needs expensive NDT [non-destructive testing] for quality assurance, which is often still not sufficient. With purely mechanical joints, with no adhesives, it’s a lot more easily repeated, easily inspected, and doesn’t rely so much on human interaction with the part.”

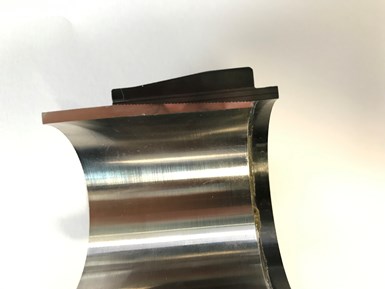

The patented tooth joint technology consists of screw-like matching grooves on both the metal and composite connection points, tapered ends and a composite hoop ring on the exterior of the joint.

Collins Aerospace set out to design a composite-to-metal joining technique that is adhesive-free, cost-effective to manufacture and transfers axial loads efficiently. The company has several patented joining technologies in development, but one, called a tooth joint, is the farthest along at technology readiness level (TRL) 6. Bernard explains that the joint is similar to a mechanical threaded connection — including screw-like matching grooves, or flanks, on both parts that need to be joined — but with some differences. In a typical threaded joint, he says, only half of the flanks on the thread are in contact, which can lead to separation when load is added to the joint. This movement of the composite part against metal can lead to fretting.

In Collins Aerospace’s patented tooth joint, the composite tube is designed to taper at the end, to the flanks, to match more exactly and prevent the metal tearing through the composite part. “This also gives us a massive boost in strength,” Bernard says. In addition, a hoop ring component, also made from composites, is placed over the top of the joint, to sandwich the tube and metal end fitting together and put the joint under radial compression. “When you fatigue this tooth joint, the flanks never lose contact; in fact, even below a micron, the composite doesn’t move relative to the metal teeth,” Bernard says.

The company aims to increase efficiency and automation for its filament-wound, straight composite tube structures, while investing in new technologies for more complex shapes and lower-cost processes.

He adds that the team decided against developing an adhesively bonded joint, which would have been another common option, because even though a bonded joint may be stronger at room temperature, “at the hot/wet environmental conditions, the bonded joint is much weaker,” he says. “At 100°C and fully saturated with moisture, a bonded joint kind of drops off a cliff, whereas the tooth joint only loses 10-15% of its room temperature unsaturated strength.” A riveted joint was also ruled out because it weakens the composite tube and adds weight to the part.

The simplicity of the composite tube and the joint enables “a very repeatable process,” Meddes says, “with a high level of automation.” Bernard notes that the filament winding process is fully automated, from the initial resin mixing through winding, curing and mandrel extraction. Target applications include wingbox and landing gear struts and interior rods at a variety of widths and lengths.

Holistic, automated process: Braided preforms and RTM

The company’s joining technology is the farthest toward commercialization, but Collins Aerospace’s Banbury facility is also diversifying by investing in braiding technology and automation for the development of complex-shaped pipes, pressure vessels, battery housings and other end-use products.

“We’re looking to diversify our manufacturing capability,” Meddes explains. “We have a large number of automated filament winding machines, which produce excellent products with excellent performance. But the main aim is to try and produce composite components as closely matched price-wise to metallic structures, so we have started looking into other manufacturing methods that can be done at a lower cost and produce products faster.”

Bernard notes that, initially, prepregs were the favored material type for this diversification, thanks mainly to their robust material properties and the fact that many are already widely qualified in the commercial aerospace industry; however, prepregs are expensive to produce. This prompted Collins to consider alternatives. “The industry, in my eyes, is moving towards [less expensive] resin infusion processes,” Bernard says, “especially with the emergence of snap-cure resin systems reducing in-mold times to only a few minutes, opening the door for RTM [resin transfer molding] and use of dry fibers.”

This strategy led to investment in a Herzog (Oldenburg, Germany) multi-axis braider and, Meddes says, a new R&D facility, currently under construction, dedicated to automated braiding and RTM technologies.

With the new addition of a Herzog braider, Collins Aerospace aims to use braided preforming to produce more complex-shaped aircraft components.

“It’s not just braiding technology,” Bernard explains, “but a holistic process, from braiding [a preform] to resin transfer molding.” The Herzog machine braids directly onto specially designed mandrels; braided preforms are then loaded onto an RTM tool for infusion. “What’s new is how we’re making the mandrel, and we’ve built the braiding and the RTM process around that,” he says. The process as a whole is currently at TRL 4, and a couple of years away from being ready to offer to customers.

With this new process and technology, Collins Aerospace intends to expand from its signature straight pipes and transmission shafts into more complex-shaped and curved tubular structures. The impetus for this is the company’s work producing glass fiber composite fuel pipes for Airbus. For years, the company has been producing these components for the A350, which are designed with a conductive particulate added to the matrix. The particulate makes the pipes partially conductive and thus able to dissipate static charge buildup caused by fuel running through the pipes. The pipes are not so conductive, however, that they draw lightning strikes into the fuel systems. At the time that it won the A350 fuel pipes contract, technology limits allowed Collins Aerospace to only build straight pipes, which restricted how the aircraft fuel system could be designed.

“For the next generation of planes, we need both a partially conductive pipe and one with complex shapes to enable OEMs to have greater flexibility in developing composite wings, without the constraint of straight fuel pipes,” Bernard explains.

In addition to complex-shaped pipes, the facility is also expanding its braided preform technology to include braided pressure vessels for storage of oxygen, as well as gaseous and liquid hydrogen for applications in the aerospace and automotive markets. Collins Aerospace hopes to offer a wide range of size options for its braided, lined Type IV and linerless Type V composite storage tanks. “We think a braided preform and RTM solution will give us a quicker production time [compared to other pressure vessels currently on the market], and therefore, an attractive cost,” Meddes says.

Related Content

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreAirbus selects Airborne to supply automated ply placement system

The pick-and-place system with software-driven automated will be the first in Airbus facilities, enabling highly efficient and flexible dry fiber preform manufacture for A350 structures.

Read MoreRead Next

Braided preforms and resin infusion for next-generation aerocomposites

Spintech shows significant cost and labor savings using its Smart Tooling, dry fiber preforms and RTM/VARTM technology on aircraft wing and inlet duct demonstrators.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)