Composite profiles bring consistent quality to Ant-X drones

Italian drone solutions provider enlists Exel Composites to deliver pultruded and pull-wound profiles that support prototype drone structure designs.

In 2020, a group of engineers working in the drone research lab at Politecnico di Milano, Italy (PoliMI) used their expertise in drone design, integration, flight testing and production to form new spinoff company. Today, Ant-X is a custom drone solutions provider with one foot in the research sphere of PoliMI and the other in the rapidly expanding global drone markets. Aware that the mechanical properties of composite materials — stiffness, durability and light weight — suit drone component requirements, Ant-X went in search of third-party composite suppliers, finally exclusively enlisting Exel Composites (Vantaa, Finland).

Remote-controlled drones are becoming increasingly popular in many sectors, such as transportation of goods and passengers, inspection, and defense, where being lightweight is critical. In addition, flight stability has fine margins and relies heavily on a drone’s configuration, so stiffness in strenuous, windy environments is necessary to remain airborne. Persistent exposure to the elements also demands resistance to corrosion and water damage. These are all important qualities that materials such as carbon fiber specialize in.

In the past, Ant-X relied on multiple third-party suppliers to source its composite structural units. This led to problems with delivery and quality, as the company had multiple supply chains and business relationships to manage, adding to its administrative burden. In particular, the quality of carbon fiber components supplied was inconsistent across the different suppliers, which made it more difficult for Ant-X to manufacture reliably performing drones.

“The known and repeatable mechanical properties of pultruded composites mean that they perform reliably and thus reduce variability and uncertainty in Ant-X’s engineering processes.”

“We found we didn’t have enough control over the timescales, the raw materials used and the general decision-making about the supply chains behind the composites we were receiving,” Simone Panza, CEO of Ant-X, says. “Insufficient influence over these aspects meant unstable foundations for design, prototyping, testing and production; we struggled to innovate in the ways that we intended.”

Meeting to decide the medium- to long-term direction of the company, Ant-X resolved that it was time to unite its composite provision needs into a single sourcing stream. In June 2022, the Italian drone company decided to take a new approach and reached out an entirely new composites partner, Exel Composites, to inquire about a solution.

“We turned to Exel Composites because of its reputation as a market leader and an expert in pultrusion and pull-winding manufacturing processes,” Panza explains. “Exel stands out for its ability to help customers overcome challenges using composites. As a company founded on our commitment to R&D and prototype design, we wanted a provider with the flexibility and expertise to help us innovate; and we found one.”

Exel Composites first supplied Ant-X with standard carbon fiber tubes for the testing stage, but soon decided a degree of specialization was needed.

“We specialize in custom composite solutions at Exel,” Luigi Cannone, area sales manager in Italy for Exel Composites, notes. “We began by providing standard pull-wound carbon fiber tubes, but we wanted to go deeper with Ant-X’s needs to understand how we could support prototype drone structure designs. We recognized the issues Ant-X had previously encountered with inconsistent composite parts and decided together that supplying modular pieces would be advantageous because of the continuous nature of pultrusion and pull-winding.”

In both of these processes, composite profiles are formed from resin-impregnated fibers which are pulled into a heated die that molds them into the desired shape. Finally, the profiles are cut to the specified length in line with the continuous process.

“The only limitations on length for cut sections are storage and transportation,” Cannone says. “The ability to run the same profile continuously through the manufacturing process yields high volume efficiency and technical advantages for the end customer. It’s more efficient to make composites this way than with more manual processes like prepreg where you need to stop and reset the machine. With pultrusion and pull-winding, the tubes that you get out are consistent batch-to-batch, both in their properties and behavior, as well as quality.”

“Ant-X cited this uniformity as a major reason for both wanting to change their supplier situation and wanting to work with Exel specifically,” Cannone continues. “The known and repeatable mechanical properties of pultruded composites mean that they perform reliably and thus reduce variability and uncertainty in Ant-X’s engineering processes.”

Composite-fueled innovation

In July 2020, a drone inspections company approached the Italian startup to develop a drone-based solution that could bring a payload featuring a sensor into contact with insulators on high-voltage powerlines, in order to collect measurements useful for maintenance purposes.

Such a tool would be of extreme interest to powerline infrastructure management companies and to maintenance operator companies: the drone would replace the need to send a human operator in proximity of the insulator to collect measurements, resulting in increased safety for workers, and reduced time and cost to carry out the operation.

As the drone needed to establish contact with an insulator and push a sensor against it, the conventional multi-rotor configuration with coplanar rotors was not suitable. It would not be able to handle contact with the environment and would have become unstable when trying to push against an object.

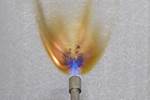

Using a non-conventional configuration featuring fixed-tilted rotors, Ant-X engineered the Aries smart drone to be capable of carrying an overhang payload and generating stable horizontal movement without disrupting flight even when establishing contact forces with its environment. Such a tool, developed for contact inspections of powerlines, is in principle capable of conducting nondestructive testing (NDT) contact inspections of many other infrastructures, for example civil infrastructures such as bridges or viaducts.

“The Aries drone is exactly the kind of project that Exel Composites’ supply will allow us to complete more of. Its composites are reliable, consistent and high-quality: exactly what we need to realize our designs. Our communications with Exel have been easy and clear throughout the partnership and its team is always enthusiastic to help us meet custom requests for upcoming projects,” Panza says. “Exel’s vision is aligned with ours and their support provides a strong foundation that we can continue to build on. I look forward to a long, mutually beneficial relationship.”

For additional related case studies, read “Exel Composites pultruded rods enhance Umbrosa parasol durability.”

Related Content

FST-rated thermoset resin with rapid, tunable cure is designed for infusion

CAMX 2023: The nonhalogenated Harp Rapid resin system presented by Trimer Technologies achieves a low-temperature, tunable cure while attaining high mechanical properties, demonstrating its effectiveness in aerospace applications.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

Read MorePulFlex introduces pultruded Flex Connect

Fiberglass T-slot, primarily used for automation, framing and other quick setup systems, competes with aluminum alternatives.

Read MoreBiocomposite for mobile architecture, low load-bearing applications

The German Institutes of Textile and Fiber Research and partners have developed a biocomposite well suited for support profiles and connecting nodes in construction applications.

Read MoreRead Next

Composites enable massive wastewater infrastructure project

To build complex drop shafts for New Zealand’s Central Interceptor project, RPC Technologies pushed the limits with glass and carbon fiber, vertical filament winding and UV-cure resins.

Read MoreExel Composites releases FST requirements guide for composites

In its latest white paper, Exel navigates the fire, smoke and toxicity (FST) considerations and complexities that can influence composites design.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More