Continuous Composites, Arkema partner to advance continuous-fiber 3D printing

The companies will combine Continuous Composites' CF3D process with Arkema's photocurable resins to develop and certify composite 3D-printing solutions.

Source | Business Wire

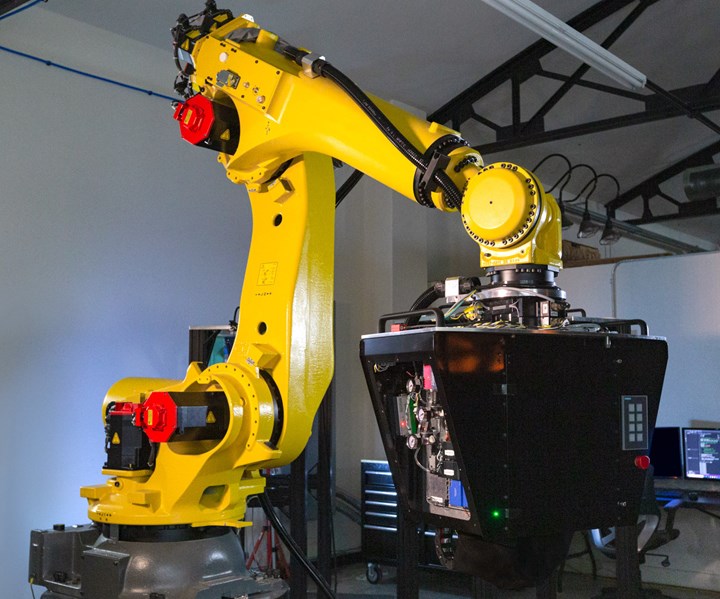

This week, Continuous Composites (Coeur d'Alene, Idaho, U.S.) announced a strategic partnership with Arkema (King of Prussia, Pa., U.S.), through its Sartomer business line, to combine Continuous Composites’ patented Continuous Fiber 3D (CF3D) Printing technology with Arkema’s photocurable resin solutions, to accelerate the advancement of additive manufacturing with composite materials.

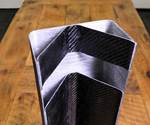

CF3D (reported on previously by CW, including a 2018 article and in a March 2019 feature) combines composite materials with a snap-curing 3D printing process to create a moldless, out-of-autoclave (OOA) manufacturing technology. The result is a scalable technology that is said to significantly reduce the cost of manufacturing with composite materials. Igniting the growth and adoption of manufacturing with composite materials, CF3D reportedly decreases lead times, reduces manual labor, removes the need for expensive capital equipment and enables complex geometries to be printed.

The combination of CF3D with Arkema’s advanced resins and laboratory testing facilities will reportedly enable development and certification of high-performance and lightweight material solutions. Through this strategic partnership, a library of advanced material solutions is expected to be established and commercialized.

“As an industry leader in materials, our strategic partnership with Arkema opens the door for us to merge CF3D with their cutting-edge UV curable materials and apply Arkema’s long history in the composites field,” says Tyler Alvarado, CEO of Continuous Composites. “This partnership will expedite the development and deployment of CF3D across a broad spectrum of industries and applications.”

“With Continuous Composites’ strong technical team and IP, this strategic partnership allows us to develop and position our materials with this revolutionary technology,” says Sumeet Jain, global business director for 3D printing at Sartomer. “We are excited to leverage our materials expertise in developing CF3D, disrupting traditional composites manufacturing, and bringing these advanced composite materials to new industries.”

Related Content

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

-

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

.jpg;width=70;height=70;mode=crop)