Continuous Composites selected by NASA for low-CTE open isogrid composite structure

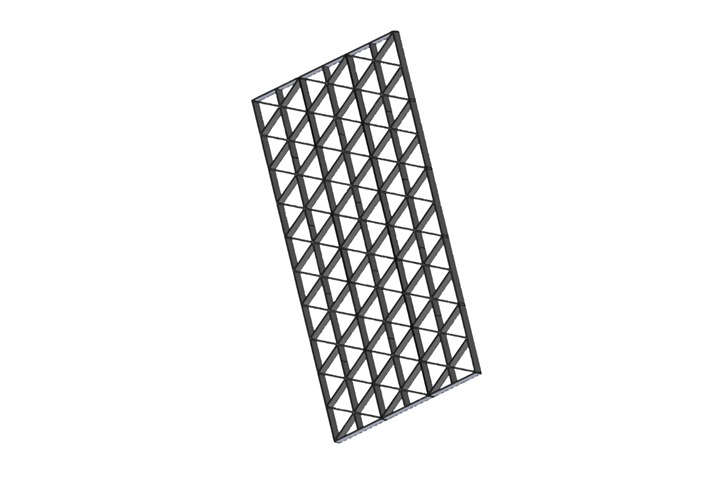

This NASA award will demonstrate CF3D’s robotic steering of individual, continuous carbon fiber tows to print and test a flat 1.6- x 3.3-foot open isogrid rib structure, which will have a low CTE.

Continuous Composites (Coeur d’Alene, Idaho, U.S.), an advanced composite 3D printing technology company, has been chosen by NASA’s (Washington, D.C., U.S.) Small Business Innovation Research (SBIR) Program to additively manufacture low coefficient of thermal expansion (CTE) open isogrid composite structures for space applications, using its patented Continuous Fiber 3D Printing (CF3D) technology.

In space, objects orbiting Earth experience drastic temperature changes when on the dark side of the earth compared to the light side. Therefore, precision objects such as satellites and optical benches require low to zero CTE to prevent warping or distortion from the expansion and contraction due to the significant temperature swings.

Continuous Composites says this NASA award will demonstrate CF3D’s advanced robotic steering of individual, continuous carbon fiber tows to print and test a flat 1.6- x 3.3-foot open isogrid rib structure, which will have a low CTE. CF3D-printed isogrid structures can reportedly be deposited onto a support surface of many different shapes, including flat, cylindrical, spherical, conical, etc. The resulting part can be optimized for the desired strength and stiffness depending on launch and space loads.

CF3D’s use of continuous fiber reinforcement, snap curing photopolymers and advanced robotics also enables the manufacture of composite structures which are impractical to produce with traditional fabrication methods more efficiently and at reduced costs. One such structure is this open isogrid rib structure, the company notes, which has applications in many industries, including space and aerospace.

“Given my background in composite design for space applications, I’m excited to demonstrate our unique fiber steering capabilities for this NASA project. This printed isogrid will have little to zero CTE which is the goal for these types of space structures,” John Brendel, application engineer and technical POC on this NASA SBIR, says. “This contract builds upon the work we have been doing in the DOD [Department of Defense] and commercial aerospace sector, and we’re excited to introduce our capabilities to the space industry.”

Related Content

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.