CF3D technology developments for continuous fiber AM applications

Studies conducted by Continuous Composites, Lockheed Martin and the Air Force Research Laboratory advance aerospace applications of continuous fiber additive manufacturing.

Share

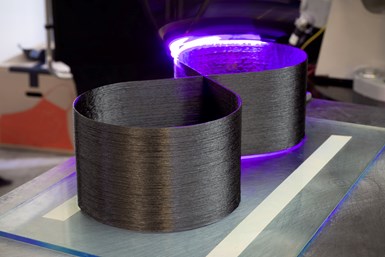

Photo Credit, all images: Continuous Composites

Based upon its foundational family of patents dating from 2012, Continuous Composites (Coeur d’Alene, Idaho, U.S.) has developed a process for continuous fiber 3D printing (CF3D) that utilizes dry, continuous fiber with UV snap cured thermoset resins. The resulting system produces true composite components within an additive manufacturing (AM) framework. Recent research and development (R&D), originally reported in the November/December 2021 SAMPE Journal, reviews continuous fiber AM as conducted on the CF3D technology, composite material developments and areas for future composites development.

Hardware development

The CF3D hardware system consists of a high-precision, high build volume, robotic platform that dynamically steers continuous fibers. The end effector provides in-situ wetting, consolidation and curing of the composite material as it is being additively manufactured (a diagram of this process can be viewed in this article, “Commercializing UV-curable thermosets for continuous fiber 3D printing”). SAMPE reports that rigorous lab testing, down-selection and a build upon previous iterations has led to the current CF3D end effector, which involves real-time active controls in each critical subsystem to accommodate challenges presented by continuous fiber manufacturing.

Active control systems manage fiber tension, creel torque, alignment, fiber cross-section geometry, impregnation, feed distances, cut positions, compaction and UV cure dose. A custom-designed no-pulsation pump system and hydrostatic impregnation module ensure accurate, consistent and user-specified fiber volume fractions. After impregnation, several fiber-handling subsystems direct, feed, clamp, cut and deliver a wetted tow to the tool center point (TCP).

CF3D end effectors have been deployed for use on both articulated robotic arms and gantry systems, but Continuous Composites has predominantly focused on working with robotic and numerical control manufacturers and precision linear drive component manufacturers to increase the accuracy of the manufacturing system. Precision laser trackers, scanners and static and dynamic compensation models have also been implemented for optimizing process accuracy and repeatability.

Material development

CF3D utilizes off-the-shelf fibers combined with custom resin solutions developed with Arkema (Colombes, France) and Sartomer (Exton, Penn., U.S.) as reported by CW. A wide availability of various commercial fibers (i.e., dry carbon, glass and aramid fiber like Kevlar, Spectra, Xylon and Dyneema; metal wire; and fiber optics) and the custom polymer UV snap cured thermoset resin enable the creation of products to meet specific application requirements and enhanced functionality. Continuous Composites and Arkema/Sartomer have also developed additional atypical matrix systems. These new material combinations will enable additive manufacturing of carbon-ceramic, carbon-carbon and ceramic-ceramic composites.

Future composites design

Cost-effective fabrication of topology optimized designs as well as structurally integrated multifunctionality are two capabilities of interest to Lockheed Martin (Bethesda, Md., U.S.) as it works with the AFRL to deliver Low Cost Attritable Aircraft (LCAA).

According to the SAMPE Journal (p. 17), current aerospace engineers mostly use topology optimization at the concept level of a design process. The free forms that naturally occur result in difficult-to-manufacture concepts. The problem is further magnified in structural composites incorporating continuous fiber reinforcement, often requiring tedious hand layup and complex hard tooling for composite consolidation and curing. CF3D’s ability to place, consolidate and snap cure without tooling support makes the manufacture of fully topology optimized design concepts possible, thus the interest in conducting more studies in this area.

In addition to reducing the costs associated with building topology optimized designs, Continuous Composites has also demonstrated the ability to embed fiber optic filaments and nichrome wires for in-situ cure monitoring and structural health monitoring (SHM) capabilities. The company has discovered, for example, that light sensing and light emitting fibers can be used in tandem to sense ice on the surface of composites, and nichrome or other embedded conductive wires can be used to deice the leading edges of wings. Other fibers in development include temperature sensing and energy storing fibers. In addition to functional fibers, polymers are in development that can be doped with additives for additional functionality such as manipulation of waves across the electromagnetic spectrum and electrical properties.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Continuous Composites demonstrates CF3D technology for Lockheed Martin, AFRL WiSDM project

Continuous Composites carbon fiber wing spar structural performance achieves 160% design limit load with no damage detected, offers potential for aerospace-grade composite printing.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More