Development of dry fiber preforms and other technologies for Smart Rotors

Airborne, KVE Composites, RHIA, Royal NLR and TU Delft partner in EU project for ultra-efficient propeller/rotor blades in hybrid and electric aircraft, UAM and drones.

An important step towards more sustainable aviation, as well as parcel and passenger transport via drones, was taken with the €1.44 million grant awarded to the Smart Rotors project by the European Fund for Regional Development (EFRO). With the cooperation of InnovationQuarter, the grant enables the Dutch partners Airborne, KVE Composites, RHIA (Rotterdam The Hague Innovation Airport), Royal NLR and TU Delft to advance development of ultra-efficient propeller and rotor blades, specifically for hybrid and electric aircraft, urban air mobility (UAM) and drones.

Smart Rotors: Why?

The development of ‘smart rotors’ is an important step towards more sustainable aviation, less emissions and less noise pollution, as well as parcel delivery via drones and will also support the further development of UAM.

Rotors can be either the blades of a propeller intended for the propulsion of aircraft or the blades of a rotor intended for the propulsion of helicopters and drones. The project aims to design the rotors for hybrid and electric aircraft and for drones so that they operate more efficiently, perform better and produce less noise.

“In addition, smarter production methods are being looked into, so that future aircraft and drones can be equipped with suitable propeller and rotor blades faster and on a larger scale,” says Ruben Nahuis, technical project leader at Royal NLR. The project is part of the Next Aviation Fieldlab, which focuses on developing, testing and implementing sustainable aviation technology in a real airport environment at Rotterdam The Hague Airport (RTHA).

Propellers: More efficient, less noise

Densely populated areas around airports experience nuisance from flight activities, such as local climate and noise pollution. The project contributes to a reduction of local climate effects in the form of fewer emissions and less noise pollution in and around the airport, with a positive effect on the immediate living environment.

Tomas Sinnige, Assistant Professor at TU Delft, explains how smart propellers contribute to the emission reduction that can be achieved: “Propellers are more energy-efficient than jet engines. The savings on fuel and thus emissions can be as much as 25% depending on the type of aircraft and the circumstances. And if you combine propellers with electric motors, you can also greatly reduce noise emissions, up to 8 to 20 decibals for regional aircraft, for example. But then you have to design the rotors in such a way that their noise emissions are minimal with the highest possible propulsion efficiency and that is exactly what we are going to investigate in this project.”

More efficient production

In addition, smarter production methods are being explored, so that future aircraft and drones can be equipped with suitable propeller and rotor blades with less lead time and on a larger scale.

The switch to electric propulsion, perhaps even supplied with energy by hydrogen in the future, is an important step in the development of aviation. In practical terms, this often means that a device no longer has one motor with one propeller, but that a larger number of smaller electric motors are installed, each with its own propeller. “Where we used to have to make one set of rotor blades for a device, now we have to make eighteen sets of blades for a new device,” says Maarten Labordus, responsible for R&D at KVE. “The market expectation of this specific device is that hundreds of them will have to be produced per year, which also includes several thousand blades. With our current production processes, we are not automatically able to achieve these numbers.”

Sarah De Smet, program manager for Smart Rotors at automation and composites production specialist Airborne agrees. “The potential market for these electric aircraft and drones is very large and therefore the production will be at a much larger scale compared to the current aviation industry numbers,” she explains. “The current production methods can support a reasonable growth but even increasing the amount of automation with the current processes will not be sufficient to support this. During this project, we will revisit the production process, develop a concept production line and work on new technologies that are required to realize this production line of the future.”

Airborne’s scope includes:

- Concept design of a line for the manufacturing of the blades and identify the technology required to achieve this

- Development of technologies such as automated preforming with dry fibers

- Proof of concept (POC)/pilot line.

The South Holland region is the aviation region

“It is precisely in the region around RTHA that it is possible to develop innovations in the aviation sector,” says Miranda Janse, director RHIA. “For example, South Holland is a hotspot for aerospace activities. More than 150 companies are already working on the future of aviation. Both the surrounding area and the airport itself form the ultimate location for the realization of a testing ground and, in the longer term, the creation of an Aviation District. With this we want to strengthen the position of Dutch aviation. ”

Ruben Nahuis at NLR wants to connect many facets with this project, from research to industry: “We have a very nice consortium of partners from both the research world and the industry. By making this project a success, we can assume a leading and international position in the market.”

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

AMRC, NCC, Dowty Propellers to develop lightweight composite propeller blades

The collaborators aim to create innovative designs and manufacturing processes for braided aircraft propeller blades.

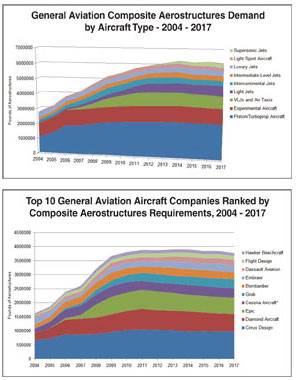

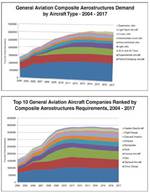

Read MoreAviation Outlook: Composite aerostructures in General Aviation

Although the math is fuzzy and once helpful category distinctions are blurring, the forecast for this sector’s use of fiber-reinforced polymer remains strong.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)