EconCore licenses Fynotej for NA automotive applications and advances into high-performance thermoplastics (HPT)

Branded Fynocore, these panels have a PP honeycomb core with skins – thermally bonded in-line – in either solid PP sheet or including a non-woven surface finish.

Fynotej (Mexico City, Mexico), a well-known manufacturer of high-quality automotive non-wovens, is the first licensee in North America focused on automotive applications for EconCore’s (Leuven, Belgium) ThermHex thermoplastic honeycomb core production technology. Fynotej began production earlier this year with a range of polypropylene (PP) honeycomb sandwich panels for automotive interiors, including trunks. Branded Fynocore, these panels have a PP honeycomb core with skins – thermally bonded in-line – in either solid PP sheet or including a non-woven surface finish, combining low weight with high performance and esthetics.

“Fynocore products combine our expertise and experience in non-wovens with EconCore’s ThermHex honeycomb technology,” says Daniel Kalach, VP of Manufacturing at Fynotej. “They fit very well with automotive market trends: they are recyclable, moisture inert, conversion is clean and fast, parts are high in performance but low in weight, and, most of all, costs are competitive. We are excited to be able to offer these innovative products to our customers throughout North America.”

Daniel Kalach says Fynotej is already looking at high-volume non-automotive applications that will also benefit from the performance advantages of PP honeycomb panels. The company is eyeing building and industrial applications in particular. “We are very excited about our honeycomb production line which has now been started up in Mexico City. This highly versatile technology that offers an extensive range of opportunities but most importantly it meets the most critical market needs – performance and cost efficiency,” adds Kalach.

Tomasz Czarnecki, COO at EconCore, says the successful start-up of the Fynotej production line is a significant step forward for lightweight thermoplastics honeycomb composites in the North American automotive sector. “It is one of the latest additions to our network of licensees, which now spans Europe, Asia and North America, covering applications not only in automotive, but – depending on the evolutions, potentially also in commercial transportation, building and construction, reusable industrial packaging and more,” he says.

Czarnecki goes on to highlight the success of another EconCore licensee in North America, Wabash National Corp., the region’s leading producer of semi-trailer and truck bodies. “The combination of thermoplastic honeycomb core with metal skins is another example of the versatility of the EconCore technology. The light-weighting efforts of Wabash National fit well into the market trends. The transportation and logistics markets, with regards to fuel efficiency regulations but also in view of pure cost savings targeted by fleet managers, are asking for a change.”

High-performant thermoplastic (HPT) products in PC, PA 66 and PPS

EconCore is now further exploiting the versatility of the ThermHex technology. It has broadened its focus to high-performance thermoplastic (HPT) honeycomb core materials and sandwich panels. “The high speed continuous technology has been proven to be a logical fit for high-volume applications using commodity thermoplastics,” says Czarnecki. “Now we are extending its capabilities to produce honeycomb cores in engineering plastics, including modified polycarbonate, polyamide 66, polyphenylene sulfide (PPS) and others.”

EconCore has already successfully produced and tested honeycombs in several HPTs at its recently-refurbished R&D facilities in Leuven, Belgium.

HPT honeycombs will build on the intrinsic benefits of lightweight honeycomb structures, adding improved heat resistance (useful for such products as housings for electric vehicle batteries) and very good flame resistance (critical for building panels). EconCore is also working with materials modified for FST (flame, smoke, toxicity) compliance in railway and aerospace applications. It sees substantial potential in photovoltaic (PV) panels and numerous other products too.

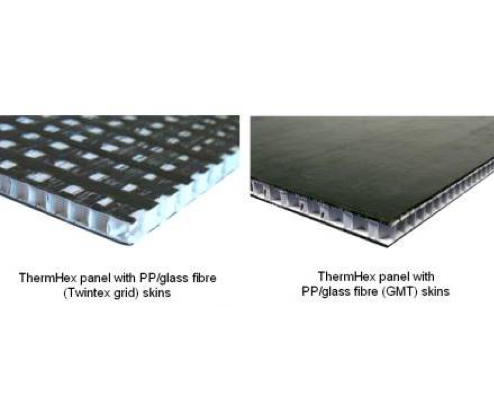

EconCore is readying a variant of the ThermHex technology for production of PP honeycomb cores thermally bonded between skins of PP reinforced with continuous glass fibers. These organosandwich materials offer an outstanding ratio of stiffness to weight and can be converted into final parts – also in-line if desired – using such quick and efficient processes as thermoforming and over-molding. Compared to more conventional composite and metal-based solutions, they offer superior light-weighting potential and important cost benefits.

Related Content

Seat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreHRC facilitates development of Karma Automotive ultra-luxury EV

Low-density GF-SMC decklids, fenders and headlamp brackets will be provided for the GS-6 EV model to achieve weight reduction and higher performance.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)