Firefly Inspect drone outfitted with infrared vision and AI to transform wind turbine, aircraft inspection

Drone technology combined with active thermography reported to offers faster, cheaper and more in-depth inspection of composites used in wind turbine blades and aircraft wings.

Two Cambridge-based companies, Innvotek (U.K.) and Mapair (U.K.), have successfully trialed a drone system that uses infrared technologies and artificial intelligence (AI) to inspect composite structures — including wind turbines and aircraft wings — for defects.

Firefly Inspect can hover above wind turbine blades and aircraft using a 1,000-watt heat lamp to test for defects. According to both companies, this is the first time that such a powerful heat source has been fitted to a drone.

Firefly Inspect was originally a concept for inspecting airplane wings when they are stationary within hangars. Thanks to a collaboration with the Offshore Renewable Energy (ORE) Catapult (Blyth, U.K.), an R&D center aiming to accelerating the creation and growth of U.K. companies in this end market, the technology has now been adapted to include inspection of on- and offshore wind turbines.

“The use of drones for asset inspection is now normal, however new inspection techniques together with increased autonomy is required to ensure operating costs remain low while gathering higher value information to make better decisions,” says Alex Williamson, director, Mapair.

During recent trials at ORE Catapult’s National Renewable Energy Centre, the drones demonstrated their ability to hover autonomously and maneuver close to vertically suspended wind turbine blades. The active thermography module enabled capture of variations in surface temperatures of blades when heated, revealing hidden imperfections that were not visible on the surface. According to Innvotek and Mapair, regular inspections, which are required to prevent small faults becoming critical failures in the composite structures, are often performed manually. However, robotics are able to offer a faster, more accurate and safer way of inspection.

Photo Credit: Innvotek, Mapair

Firefly Inspect’s ability to detect hidden structural defects and automatically locate their position using AI will help operators make informed decisions and extend the service life of composite components, both partners acknowledge. A further innovation is the use of OptiTrack motion capture technology for navigation, avoiding reliance upon GPS which can be subject to signal interference out at sea. This also enables indoor inspections (inside aircraft hangars) where GPS does not work.

“Robotic technologies offer a range of health and safety benefits while more regular and cost-effective inspections can reduce turbine downtime, but that is not the whole story,” comments Andrew Macdonald, offshore wind development and operations director at ORE Catapult. “Offshore wind is set on a course of rapid expansion across the world. The sheer scale of operations, the supersizing of turbines and their deployment ever further from shore — all these factors make human-led inspections more fraught, risky and costly. U.K. developers like Innvotek are gaining the first-mover advantage in creating the robotic and digitalized solutions of the future.”

The technology’s development was joint funded by Innovate UK and Canada’s National Research Council with additional support from Cranfield University (U.K.), Université Laval (Quebec, Canada) and BI Expertise (Quebec). The project (Multiple Robotic Inspection of Composite Aircraft Structures Using Active Thermography – MultiAcT) has been awarded the EUREKA label for outstanding research and development (R&D) achievement.

“The success of the trials is a major milestone in our overall development program. We now look to make refinements to the system as we move towards commercialization in the wind energy and aerospace sectors,” says Michael Corsar, CTO for Innvotek. “There is huge potential to reduce costs, enhance safety and generate critical data that will benefit integrity management for asset owners in both these industries.”

Related Content

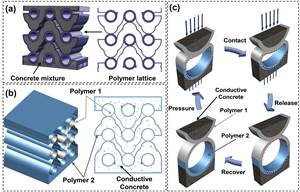

21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

Read MoreEOLIAN kicks off bio-based wind blade development

EU project will develop bio-based, repairable and recyclable vitrimer composites and advanced sensors for highly reliable, sustainable wind blades.

Read MoreAcellent SHM 4.0 software supports real-time composites monitoring

Integrity and condition of a variety of metal and composite parts and structures is made possible through end-to-end software suites.

Read MoreAcellent contracted to supply SHM systems for KAI KF-21 aircraft

Adaptable custom structural health monitoring (SHM) technology will be used to monitor damage and load of composite aerostructures.

Read MoreRead Next

Mistras receives patent for Sensoria wind blade monitoring technology

The remote rotor blade monitor offers edge-to-edge intelligence that detects and reports damage in real time, enabling better-informed wind blade integrity management.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More