21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

Concrete is the most used material in the construction industry and dates to the Roman Empire. Engineers at the University of Pittsburgh (Pitt, Pittsburgh, Pa., U.S.) Swanson School of Engineering are now re-imagining its design for the 21st century.

New research introduces metamaterial concrete for the development of smart civil infrastructure systems. The paper, "Multifunctional Nanogenerator-Integrated Metamaterial Concrete Systems for Smart Civil Infrastructure," presents a new concept for lightweight and mechanically tunable concrete systems that have integrated energy harvesting and sensing functionality.

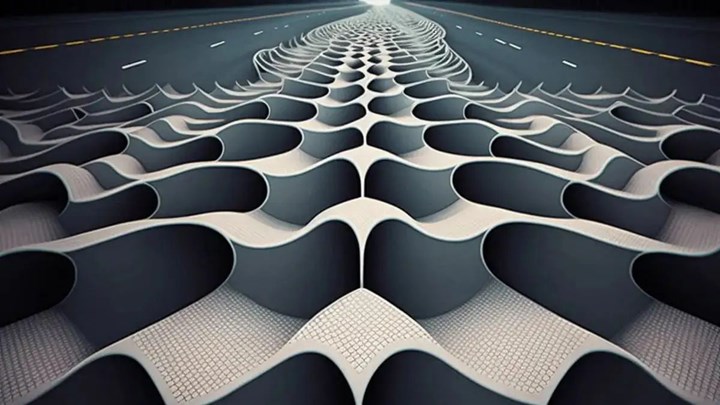

Future relevance of the proposed nanogenerator-integrated metamaterial concrete in smart infrastructure systems: a) A high energy absorbing engineered materials arresting system; b) A shock absorbent bike lane pavement; c) Metamaterial concrete base isolation system. Photo Credit: Fig. 5, “Multifunctional Nanogenerator-Integrated Metamaterial Concrete Systems for Smart Civil Infrastructure” by Kaveh Barri, Amir Alavi, et al., Adv. Mater. 2023, 2211027.

“Modern society has been using concrete in construction for hundreds of years,” says Amir Alavi, assistant professor of civil and environmental engineering at Pitt, who is the corresponding author on the study. “Our massive use of concrete in infrastructure highlights the need for developing a new generation of concrete materials that are more economical and environmentally sustainable yet offer advanced functionalities. We believe that we can achieve all of these goals by introducing a metamaterial paradigm into the development of construction materials.”

Alavi and his team have previously developed self-aware metamaterials and explored their use in applications like smart implants. This new study introduces the use of metamaterials in the creation of concrete, making it possible for the material to be specifically designed and tailored in its attributes such as load-bearing capability, flexibility and shapeability. These can be fine-tuned in the creation of the material, enabling builders to use less material without sacrificing strength or durability.

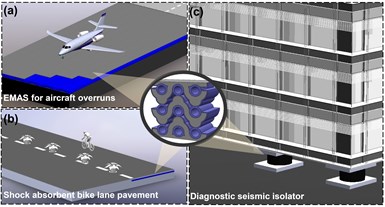

Multifunctional metamaterial concrete. a) Schematic of metamaterial concrete with 3 × 3 unit cells. b) Composition of nanogenerator-integrated metamaterial concrete matrix with embedded conductive and non-conductive layers. c) Working mechanism of the unit cells of a nanogenerator-integrated metamaterial concrete. Photo Credit: Fig. 1, “Multifunctional Nanogenerator-Integrated Metamaterial Concrete Systems for Smart Civil Infrastructure”.

“This project presents the first composite metamaterial concrete with super compressibility and energy harvesting capability,” said Alavi. “Such lightweight and mechanically tunable concrete systems can open a door to the use of concrete in various applications such as shock absorbing engineered materials at airports to help slow runaway planes or seismic isolation systems.”

The material is also capable of generating electricity — not enough to send power to the electrical grid, but more than enough to power roadside sensors. The electrical signals self-generated by the metamaterial concrete under mechanical excitations can also be used to perform structural health monitoring (SHM), measuring damage inside the concrete structure or to monitor loads and stresses during earthquakes.

Eventually, these smart structures may even power chips embedded inside roads to help self-driving cars navigate on highways when GPS signals are too weak, or when LIDAR is not working.

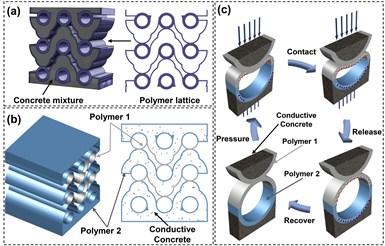

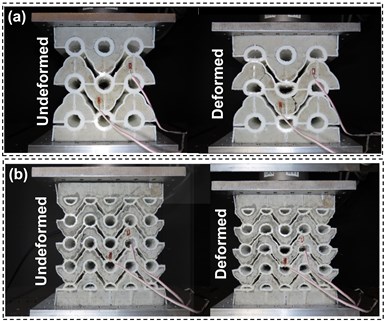

Super-compressible metamaterial concrete systems fabricated at the University of Pittsburgh with 3×3 unit cells (left) and 5×5 unit cells (right). The proposed concrete systems are tuned to achieve up to 15% compressibility under cycling loading. Photo Credit: Fig.2, “Multifunctional Nanogenerator-Integrated Metamaterial Concrete Systems for Smart Civil Infrastructure”.

The material developed at Pitt comprises reinforced auxetic polymer lattices embedded in a conductive cement matrix. The composite structure induces contact-electrification between the layers when triggered mechanically. The conductive cement, which is enhanced with graphite powder, serves as the electrode in the system. Experimental studies show that the material can compress up to 15% under cyclic loading and produce 330 microwatts of power.

Alavi and his research team are partnering with the Pennsylvania Department of Transportation (PennDOT) through the IRISE Consortium at Pitt to develop this metamaterial concrete for use on Pennsylvania roads. The project also included researchers from Johns Hopkins University, New Mexico State University, the Georgia Institute of Technology and the Beijing Institute of Nanoenergy and Nanosystems.

Related Content

Acellent SHM 4.0 software supports real-time composites monitoring

Integrity and condition of a variety of metal and composite parts and structures is made possible through end-to-end software suites.

Read MoreEOLIAN kicks off bio-based wind blade development

EU project will develop bio-based, repairable and recyclable vitrimer composites and advanced sensors for highly reliable, sustainable wind blades.

Read MoreAcellent contracted to supply SHM systems for KAI KF-21 aircraft

Adaptable custom structural health monitoring (SHM) technology will be used to monitor damage and load of composite aerostructures.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More