Fortify, Roger Corp. partner to develop 3D-printed dielectric material systems

Combination of low-loss material systems and the Flux 3D printer series’ advanced composite processing capabilities augment radio-frequency device manufacture.

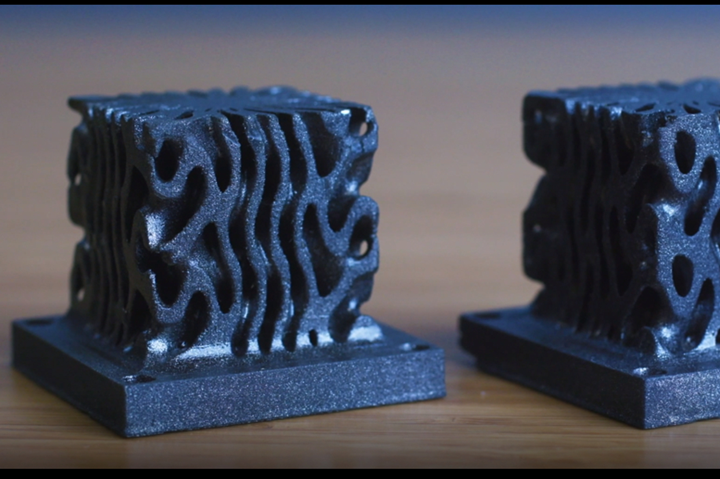

Photo Credit: Fortify

On May 25, Fortify (Boston, Mass., U.S.) a 3D printing startup, and Rogers Corp. (Chandler, Ariz., U.S.) an engineered materials company for advanced connectivity and power electronics, announced a partnership to enable the additive manufacturing (AM) of low-loss dielectric materials for radio frequency (RF) devices and electronics using Fortify’s Flux 3D printer series for fiber- and particle-filled photopolymers.

The partnership will allow the leveraging of both company’s areas of expertise to unlock scalable manufacturing of high-value RF components. For example, Roger Corp.’s market dominance in low-loss, RF materials and Fortify’s advanced composite processing capabilities will enable customers to efficiently design and print precision substrates, Luneberg-like Gradient Refractive Index lenses and end-use components. Fortify’s Continuous Kinetic Mixing (CKM)-powered digital light processing (DLP) platform enables high-throughput production of fine-featured parts out of heavily loaded materials that are otherwise difficult to process.

“As our world becomes increasingly connected, so does the need for faster and higher capacity wireless connections,” Trevor Polidore, new product development group leader at Rogers Corp. says. “Partnering with Fortify will allow Rogers to deliver a complete solution for the manufacturing of 3D-printed dielectric components, enabling our customers to create the next generation of wireless systems.”

Complex 3D dielectrics have historically been difficult or impossible to manufacture with the necessary cost, quality and repeatability to meet practical manufacturing requirements.

According to Roger Corp., wireless communications and SATCOM systems have led the expansion of active antenna systems (AAS) use into mainstream consumer applications. By taking advantage of AAS’s ability to generate highly directive signals that can be electronically steered and form various beam patterns, the latest applications such as 5G and high-throughput satellites (HTS) can reportedly deliver services previously inaccessible with conventional antennas.

However, many AAS technologies are expensive and complex to manufacture, Roger Corp. says, with multitudes of performance tradeoffs that often require new technologies and high-cost devices to yield competitive solutions. The company says it is possible to address some of these challenges with intricate 3D dielectric materials, but complex 3D dielectrics have historically been difficult or impossible to manufacture with the necessary cost, quality and repeatability to meet practical manufacturing requirements.

“The photopolymers available today are an order of magnitude more lossy than thermoplastics, yet 3D printing complex parts at scale out of thermoplastics is time consuming,” Phil Lambert, senior applications engineer at Fortify notes. “With the right low-loss material systems from Rogers combined with Fortify’s printers, we can offer a solution that provides excellent feature resolution, great RF properties and high throughput capabilities for end-use parts.”

While traditional DLP platforms struggle to print highly viscous materials, Fortify says, the CKM technology employed on all Fortify Flux Series printers allow for the processing of advanced materials, such as Rogers’ low-loss materials, while maintaining material quality and consistency throughout the manufacturing process.

“With Rogers, we are positioned to commercialize the first scalable, low-loss 3D-printed RF dielectric materials,” Josh Martin, CEO and co-founder of Fortify says. “This partnership is a great example of how innovative materials and technology companies can come together and provide a differentiated value proposition to a rapidly growing market. Fortify has a scalable way of manufacturing continuously varying dielectric material, which is a game changer for the scanning beam antenna market [5G, surveillance, remote sensing and security].”

New application technology include passive lens devices that augment gain and directivity for single- or multi-feed systems found in RF sensing and SATCOM On-The-Move commlinks, and 5G AAS systems to widen field of view and reduce sidelobe levels.

Fortify’s says the advantages of its 3D printers for printed RF dielectric technology include: lower weight, wide bandwidth, scalable manufacturing, structure design freedom, quick turnaround parts and more. The two companies continue to collaborate to optimize printing processing parameters to realize all these benefits and more.

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)