FRP bridge prototype uses large-scale 3D printing

Royal HaskoningDHV, CEAD and DSM produced a pedestrian bridge prototype using large-scale additive manufacturing of continuous fiber-reinforced thermoplastics.

Source | CEAD

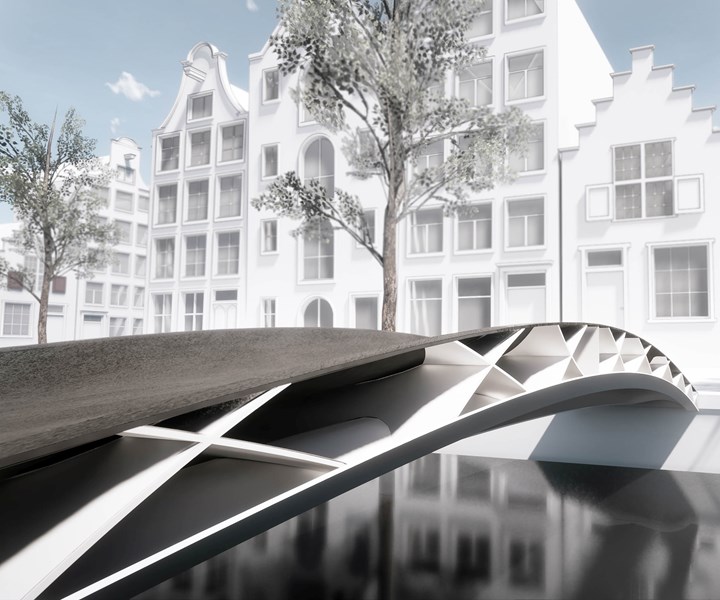

Royal HaskoningDHV (Amersfoort, Netherlands), CEAD (Delft, Netherlands) and DSM (Amsterdam, Netherlands) have designed a lightweight, 3D-printed, fiber-reinforced polymer (FRP) pedestrian bridge prototype. The bridge consists of a glass fiber-filled thermoplastic PET (Arnite) reinforced with continuous glass fibers during the 3D printing process. This combination is said to offer high strength, versatility and sustainability.

To build the bridge, Royal HaskoningDHV, an international engineering and project management consultancy, partnered with DSM, a global science-based company whose specialties include 3D printing materials, and CEAD, supplier of 3D printing equipment including large-scale composite additive manufacturing machines.

Watch the 3D-printing process:

“This partnership is bringing about a paradigm shift in the way we think about the form and function of bridges in our society,” says Maurice Kardas, business development manager at Royal HaskoningDHV.

According to Kardas, sensors are included in the design, enabling them to build a digital twin of the bridge that can predict and optimize maintenance. The sensors, he says, can also incorporate functionalities like monitoring environmental aspects and providing real-time reports on bridge conditions.

The companies used their combined experiences in generative design and predictive modelling to design a more efficient bridge, optimizing the printing process and eliminating waste material.

Source | CEAD

“Using a material such as Arnite has huge benefits for the construction of bridges. Rather than using traditional materials such as steel or concrete, these bridges can be much more sustainable and offer greater flexibility in design using recyclable materials,” says Patrick Duis, segment leader of additive manufacturing at DSM.

“This 3D-printed bridge prototype demonstrates the huge strides that we are making which will transform the future of this industry, not only speeding up construction, but also making the process more cost and time efficient. We developed this technology for exactly these industry applications, making them more sustainable and easier to manufacture,” says Maarten Logtenberg, CEO of CEAD.

Related Content

-

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

-

Sinonus launches energy-storing carbon fiber

Swedish deep-tech startup Sinonus is launching an energy-storing composite material to produce efficient structural batteries, IoT devices, drones, computers, larger vehicles and airplanes.

-

Syensqo becomes new Solvay specialty materials company

Syensqo represents what was Solvay Composite Materials, focused on delivering disruptive material technologies and supporting growing customer needs.

.jpg;width=70;height=70;mode=crop)