GE finalizes supply contract for Haliade-X 13 MW variant

The Dogger Bank wind farm will comprise of 190 units of the 13 MW Haliade-X wind turbine, due for completion by 2026.

Photo Credit: GE Renewable Energy

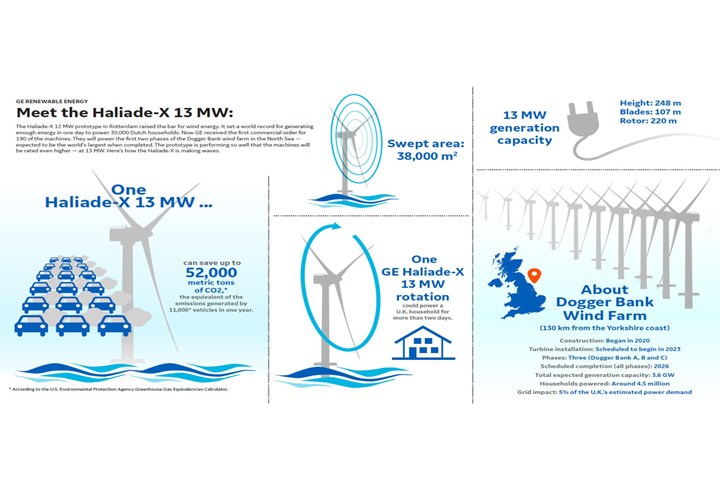

GE Renewable Energy (Paris, France) announced on Sept. 22 that it has finalized supply contracts (subject to final notification to proceed) with Dogger Bank Wind Farm off the east coast of Yorkshire, England (a 50:50 joint venture between SSE Renewables and Equinor) for the first two phases of what is said will become the world’s largest offshore wind farm. According to GE, these first two phases (Dogger Bank A and B) will each feature 95 Haliade-X 13-megawatt (MW) wind turbines. GE says this project will be the first to use these 13 MW variant wind turbines.

GE says the agreements will include a total of 190 units of the 13 MW Haliade-X wind turbine, and a five-year service and warranty agreement to provide operational support for the wind turbines. GE’s Service team will be co-located with the Dogger Bank Operational and Maintenance team, based out of the Port of Tyne (located in South Shields, England).

The Haliade-X 13 MW is said to be an enhanced version of the 12 MW unit which has been operating in Rotterdam since November 2019 and which recently secured its provisional type certificate from DNV-GL. The uprated 13 MW Haliade-X will also feature 107-meter long blades and a 220-meter rotor. One spin of the Haliade-X 13 MW is said to generate enough electricity to power a U.K. household for more than two days.

“We are delighted to take the next step in developing the most advanced proven technology in the market,” says John Lavelle, president and CEO, Offshore Wind at GE Renewable Energy. “In signing these agreements with Dogger Bank, our Haliade-X technology will now have an important role to play in the U.K.’s offshore wind ambitions [40 GW by 2030] and greenhouse emission reduction to “net-zero” by 2050.”

Photo Credit: GE Renewable Energy

It is further confirmed by GE that the project will bring economic benefits to the North East of England. The service and warranty agreements for the first two phases of Dogger Bank Wind Farm will account for around 120 of the operational and maintenance jobs that will be based from the Port of Tyne. In addition, GE Renewable Energy has also confirmed that it will establish its marshaling construction team activities at Able Seaton Port in Hartlepool, which will result in the creation of an additional estimated 120 jobs during the construction period. Recruitment activities are likely to begin early next year.

“I am thrilled to see so many green jobs on the way to the North East of England. Projects like Dogger Bank are absolutely crucial to building back greener from the coronavirus pandemic — creating jobs, growing the economy and tackling climate change. I look forward to watching its progress in the months and years ahead,” comments Energy Minister Kwasi Kwarteng.

The Dogger Bank wind farm is located more than 130 kilometers off the north-east coast of England and will be capable of powering up to 4.5 million homes each year when complete in 2026. Due to its size and scale, the site is being built in three consecutive phases; Dogger Bank A, Dogger Bank B and Dogger Bank C. Each project is expected to generate around six Terrawatt-hours (TWh) of electricity annually.

In the meantime, GE notes that the Haliade-X platform continues to undergo a rigorous series of tests at the U.K.’s Offshore Renewable Energy (ORE) Catapult testing facility in Blyth, at Boston’s Wind Technology Testing Center in the U.S. and at the prototype site in Rotterdam, Netherlands. This prototype unit in the Netherlands, which, according to GE, sets a world record in January 2020 by being the first wind turbine to produce 288 megawatt-hours (MWh) in one day, will start operating at 13 MW in the coming months as part of its ongoing testing and certification process.

Further, GE Renewable Energy will continue its testing and research and development activities on Haliade-X platform in the U.K. by partnering with ORE Catapult and other institutions to develop programs that reduce the time people spend at sea, to increase safety and the use of robotics, digital and remote operations to reduce energy costs.

Related Content

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreMingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

Read MoreAchieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More