German National Railway Certifies Essentium HSE Printing Platform, Materials

Essentium’s additive manufacturing solutions will enable Deutsche Bahn to increase its fleet availability through easy and fast replacement of parts and tools.

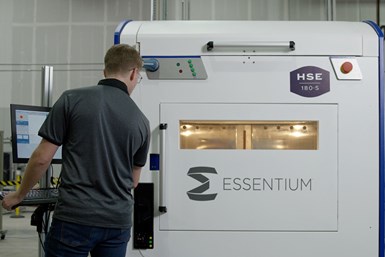

Germany’s national railway company, Deutsche Bahn (DB), has certified the use of Essentium’s High Speed Extrusion (HSE) 3D printing platform as well as its high-performance materials for 3D printed train parts and tools at the DB location in Neumunster. Essentium’s 3D printing technology, including flame-retardant Essentium 9085 and HTN-CF25 thermoplastics, has been tested to demonstrate that it complies with the AM Standard ISO/ASTM 52920:2023 and ISO 52920.

The Essentium AM solutions will enable DB to increase the availability of its fleet through fast and efficient replacement of parts and tools. By leveraging Essentium’s AM technology, DB aims to overcome supply chain issues and raw materials shortages for obsolete parts.

DB maintains a digital warehouse housing virtual technical drawings of spare parts. These parts can be 3D printed on demand, with around 1,000 models currently available. DB aims to raise the number to 10,000 components by 2030. The Essentium HSE 3D Printing Platform in Neumunster and its materials will help DB enhance delivery speed and lower costs by creating low-run parts on demand rather than mass manufacturing and storing vast quantities.

Related Content

-

Thermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

.jpg;maxWidth=300;quality=90)