Grafen AB introduces graphene-coated textiles

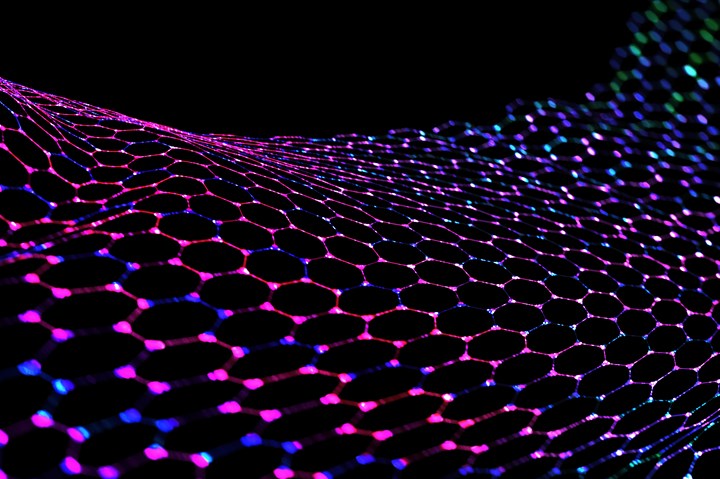

The G-Heatex series uses graphene flakes to entirely impregnate textiles for uniform electrical resistance properties. It is available for a range of textile substrate types.

Share

Photo Credit: Getty Images

Grafren AB (Linköping, Sweden) has introduced G-Heatex, a series of graphene-coated textiles, which reportedly supply powerful and uniform heat while remaining soft, flexible, breathable and ultra-lightweight.

Grafren AB has recently patented two innovations, which are now covering its full production cycle. The company now has the technology for separating high-quality graphene flakes from any grade of incoming material. The access to the high-quality graphene will enable the company to work on graphene textiles.

“We invented the method to incorporate [the] smallest flakes of graphene inside of the fabric on the nanoscale level,” says Grafren’s Technical Director, Dr. Mike Zhyback. Graphene nanoparticles — or flakes — are entirely impregnated inside the fabric and coating layer by layer in every individual textile fiber. Because of the high electrical conductivity of graphene, attached flakes create a “conductive skin” on every fiber, which makes the entire fabric electrically active. Graphene can be coated on diverse textile substrates and the electrical resistance can be tailored depending on the application requirements.

Graphene textiles are said to have applications in defense, aerospace, healthcare, mobility and automotive due to the number of functions it possesses. Grafren says it is currently focused on the heating function of the fabric, as well as creating fully textile electrical heating elements to deliver uniform, homogeneous heat. The company claims that this is the only solution of its kind on the market.

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.