Hexagon Purus to deliver composite storage systems for hydrogen vehicle prototypes

Hydrogen storage systems will be supplier to clean mobility company, Keyou, for internal combustion engine bus and truck projects, with first deliveries slated for November 2021.

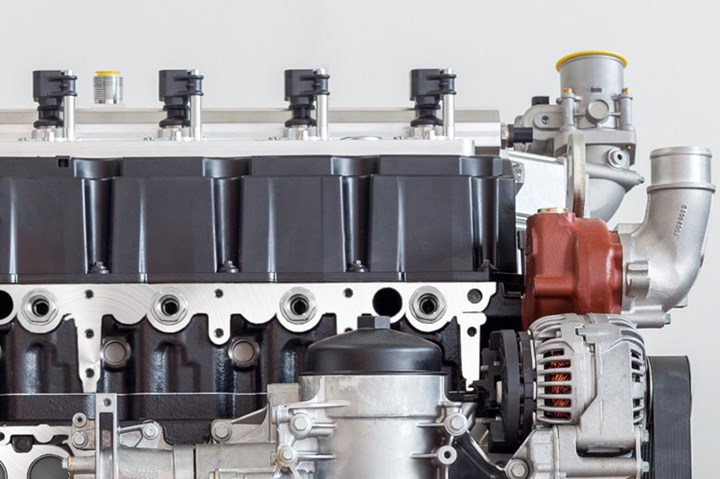

Redesigned ICE engine for hydrogen capabilities. Photo Credit: Keyou

Hexagon Purus (Ålesund, Norway) has received an order for composite hydrogen storage systems for clean mobility company Keyou GmbH (Munich, Germany). Hexagon Purus will supply hydrogen storage systems for Keyou’s H2 combustion engine DEMO bus with a leading European OEM and its DEMO truck project. Hexagon Purus’ storage systems will be supplied from its Kassel, Germany and Kelowna, Canada facilities, with first deliveries slated for November 2021.

Keyou’s successfully redesigned internal combustion engine (ICE), which can now be fueled by hydrogen, has led to a large leap in the company’s propulsion development, offering emissions-free and cost-effective options for commercial vehicles without compromising on performance, capacity or range.

“Keyou and Hexagon Purus share a common vision and a common interest —to drive the energy transition and achieve clean air everywhere,” says Michael Kleschinski, EVP Hexagon Purus. “As more European countries and cities announce strategic policies to promote the decarbonization of mobility, more commercial vehicles — especially city buses and heavy-duty trucks —will be rapidly transitioned. Keyou is dedicated to accelerating this development, and we are pleased to be a part of this project.”

This order follows Hexagon Purus’ agreement with Air Liquide and its selection by Nikola Corp. to further develop the company’s Type IV hydrogen cylinders.

Related Content

-

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

-

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.