Hexcel HexPly M79 prepregs receive DNV GL Type Approval Certification

The new verification allows the materials to be used in all DNV GL classed vessels.

Source | Hexcel

Hexcel (Stamford, Conn., U.S.) announced on May 5 that its HexPly M79 prepreg materials have received Type Approval Certification by DNV GL (Oslo, Norway). This third party verification allows HexPly M79 materials to be used in all DNV GL classed vessels and provides ship and boat builders with additional independent assurance of the product’s quality, performance and consistency, Hexcel says.

Hexcel has supplied advanced composite materials to the marine industry since the 1970s and supplies a comprehensive range of products including woven reinforcements, multiaxial fabrics and DNV GL certified prepregs.

The company says its HexPly M79 prepregs are suited to marine composite applications since they can be cured at temperatures as low as 70°C for eight hours or 80°C for four hours, reducing tooling costs and increasing build rates.

The latest DNV GL Type Approval Certificate includes:

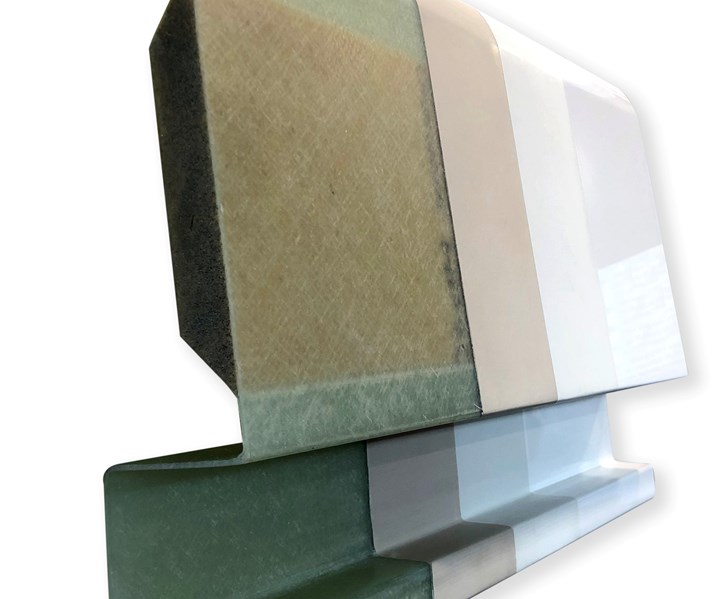

- HexPly M79 carbon fiber and glass fiber prepregs

- The newly launched HexBond 679 adhesive film

- Fully compatible HexPly SuperFIT semi-preg

- HexPly XF2 ready to paint surface technology prepregs

Hexcel says it is continuing to develop new technologies to help marine manufacturers improve their designs for lighter, safer and more efficient watercraft.

“This is a major step forward in establishing our M79 product portfolio in the marine market and will enable great opportunities in the near future,” says Andreas Sageder, product manager of Industrial Specialties at Hexcel. “With the new certification of the HexPly M79 product portfolio, we can now offer ship and boat builders a complete package of DNV GL approved prepreg materials optimized for low temperature curing and short cycle times.”

Related Content

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

.jpg;width=70;height=70;mode=crop)