Hufschmied virtual masterclass demonstrates machining of carbon fiber winglet

Masterclass details how to efficiently manufacture demanding components from high-performance materials with a PPS CFRP winglet as an example.

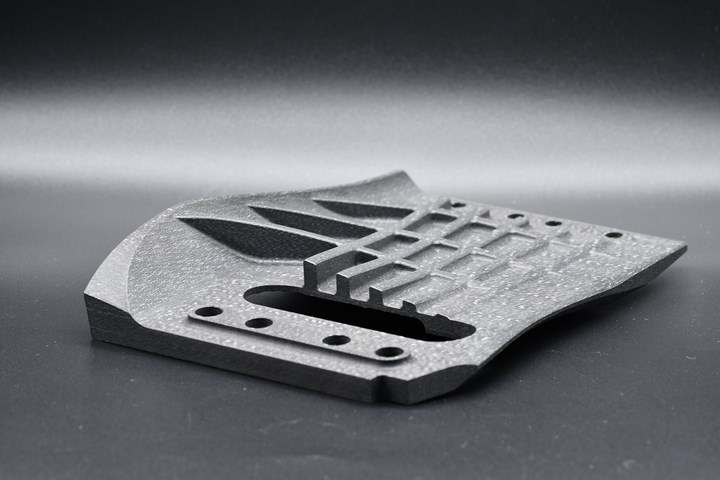

CFRP winglet. Photo Credit: Hufschmied Zerspanungssysteme GmbH

Hufschmied Zerspanungssysteme GmbH’s (Bobingen, Germany) virtual masterclass, “Machining Thermoplastic Carbon Winglet,” held on Feb. 23, 2021, demonstrated the machining of a composite winglet carried out by CNC machine manufacturer Fehlmann AG Maschinenfabrik (Seon, Switzerland) and Ensinger Composites Schweiz GmbH (Otelfingen). Now, the demonstration video is available in English.

According to Hufschmied, in order to efficiently manufacture demanding components from high-performance materials, the machine, machining strategy and tool must be coordinated. During the masterclass, Hufschmied, Ensinger and Fehlmann machined a carbon fiber-reinforced polyphenylene sulfide (PPS) TECATEC PPS CW50 PL winglet with complex free-form contours. The component was machined with Hufschmied's Graftor tools, 065SMC drill milling cutter and FB162 drill on Fehlmann's VERSA 645 linear five-axis high-performance milling center.

The virtual masterclasses, which Hufschmied hosts regularly with partners, offer manufacturing and process managers, machining technicians and machine operators concrete assistance for practical work in machining production. Dates and topics for future virtual masterclasses can be viewed here.