HX5 thermoplastic nanocomposite presents an alternative to aluminum for space applications

Alpine Advanced Materials’ HX5 demonstrated retention of 96% mechanical performance with exposure to five million rads of gamma radiation.

Share

Source | Alpine Advanced Materials

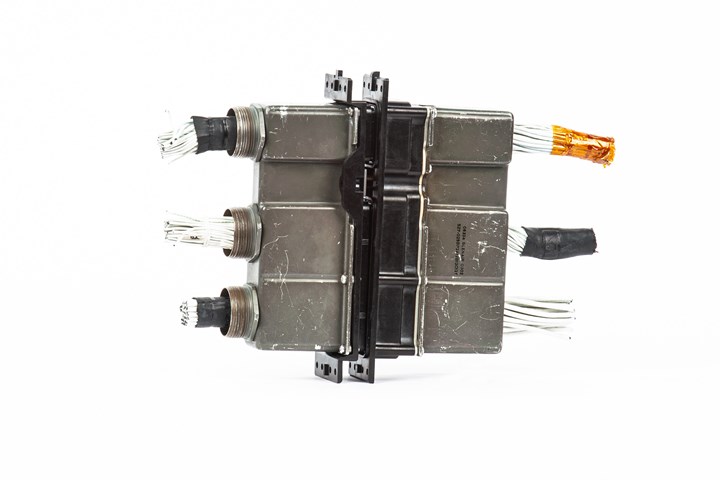

HX5, a lightweight military aviation grade thermoplastic nanocomposite offered by Alpine Advanced Materials (Dallas, Texas, U.S.) was recently reported to have demonstrated that it retains up to 96% of its original mechanical performance when subjected to five million rads of gamma radiation. Previously used for aircraft and defense applications, results from the mechanical and radiation testing performed by both the National Institute of Aviation Research (NIAR, Wichita, Kan., U.S.) and VPT Rad Radiation Lab (Chelmsfold, Mass., U.S.) are said to suggest that the material presents an alternative to aluminum for satellite providers and private companies focused on space exploration.

According to Alpine Advanced Materials, NIAR used the ASTM D6272 four-point bend test to validate and assure HX5’s uniform performance and consistency. With a reported gamma radiation-resistant up to five million rads, HX5 is said to meet the resistance requirements for satellites (around 500,000 rads), and interstellar space travel and flight (ranging from 1 to 10 million rads). Alpine says this means that traditionally aluminum parts and components used in space can now be made at half the weight.

“Reducing weight is one of the keys to making space flight both more possible and more affordable – every gram you save translates to less fuel you have to pay for and more distance you can travel,” says Roger Raley, president of Alpine Advanced Materials. “In the realm of space travel, making longer flights more achievable by reducing weight becomes a game changer.”

Developed by Lockheed Martin Skunk Works (Palmdale, Calif., U.S.), and with more than a decade of testing and validation with an R&D investment in excess of $50 million, Alpine notes that HX5 was engineered to replace machined aerospace-grade aluminum at half the weight. In addition to its durability in highly radioactive environments, HX5 is said to demonstrate high resistance to solvents, fuels, lubricants and chemicals, giving it the ability to withstand the most demanding applications. Already certified for use in rockets and satellites, HX5 reportedly satisfies NASA spacecraft limits on outgassing and radiation resistance stability, is highly temperature capable and has passed accelerated lifetime thermal cycling and high-temperature thermal stability.

“With its low thermal coefficient of expansion and low thermal conductivity, HX5 is an ideal material for use in space,” adds Peter Shpik, director of technical service for Alpine Advanced Materials. “While one surface is exposed to hot sunlight, the opposite side is in cold darkness, yielding a structure with little to no twisting or bending, and without high dimensional changes. HX5 also has little to no outgassing in a vacuum-like space, limiting the potential of material film developing on surfaces within a vehicle.”

Related Content

-

JEC World 2023 exhibit preview: Mito Materials Solutions

At the Startup Hub, Mito is availabile to discuss its ready-to-pour graphene resin options, customer applications and solutions for taking graphene from the lab to the real world.

-

Nanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

-

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.