ILAuNCH Trailblazer project to use AM technologies to produce large-scale composite rockets

ILAuNCH partnership, joined by ANU and New Frontier Technologies, will develop a qualified manufacturing process that will directly contribute to the development of launch vehicle development.

Share

Read Next

(Left to right): ANU professor, Patrick Kluth with NTF Paul Compston and Dr. Victoria Zinnecker. Source | iLAuNCH

The latest Innovative Launch, Automation, Novel Materials, Communications and Hypersonics (iLAuNCH) Trailblazer project, a $180 million program building Australia’s enduring space capability through the commercialization of projects, a fast-track accelerator and skills development, is underway to apply the design flexibility and speed of additive manufacturing (AM) technology to develop large-scale carbon fiber composite structures for rockets.

“This is another world-class approach to lay up space-grade carbon fiber and then digitally model that for scale and repeatable design,” notes iLAuNCH Trailblazer executive director, Darin Lovett. “As we make progress in developing sovereign capability for space applications, we know these products will also benefit defense, aerospace and other sectors that require high-value, bespoke composite structures.”

As in past iLAuNCH projects, this one will again use the design and advanced manufacture expertise of startup company New Frontier Technologies Pty Ltd (NFT, Canberra, Australia) to create structures suitable for launch vehicle applications, along with the Australian National University’s (ANU, Canberra) Australian Advanced Instrumentation Centre (AITC), and the X-ray Computed Tomography laboratory (CTLab) for testing.

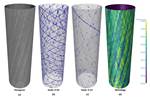

Using an ANU high-resolution CT scanner to assess and mature the manufacturing process, the collaboration will build a functional digital twin of the rocket bodies to assess, qualify and enhance the fidelity of structural models for simulation.

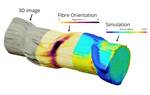

The application of X-ray CT and 3D multi-scale modeling at ANU will enable high-fidelity simulation. The CT will capture the detailed microstructure features, such as fiber alignment and voids, that can be reflected in the simulation models. 3D models will provide a detailed digital profile, with capability for performance simulation of every manufactured component, which is the foundation for digital certification.

The project lead, NFT, has developed design-for-manufacture (DfM) strategies for scalable AM of space-grade carbon fiber structures using laser-assisted automated tape placement (ATP).

“This is the only ATP manufacturing capability of its kind in Australia and has been proven in European (ESA) projects for manufacture of high-performance composite structures for space applications,” contends NFT director and CEO, Paul Compston.

ILAuNCH is a collaborative partnership between the University of Southern Queensland, University of South Australia and ANU, supported by the Australian Government Department of Education.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.